Composite material frangible cover enabling direction-pinpointed ejection and manufacturing method thereof

A composite material and fragile cover technology, which is applied in the direction of offensive equipment, rocket launchers, weapon types, etc., can solve the problems of throwing direction uncertainty, cumbersome use, and overall performance decline, and achieve simple and easy molding process, Easy to operate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A directional throw composite material frangible cover, the preparation process of which comprises the following steps:

[0019] 1) Clean the mold, apply low-temperature grease on the mold, and stick polyester fragile plastic paper;

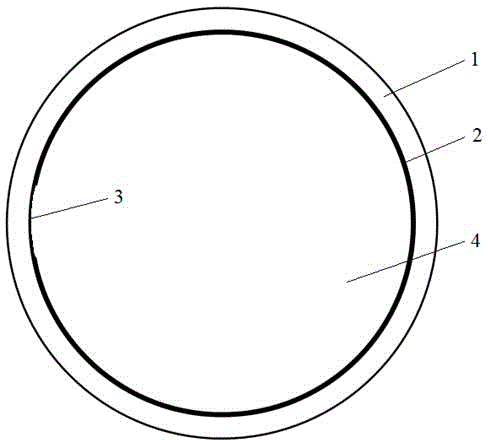

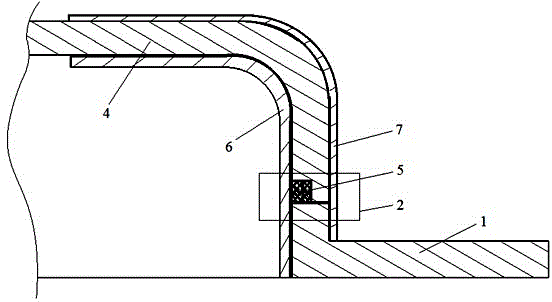

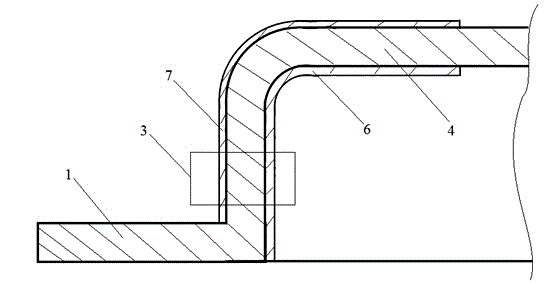

[0020] 2) Cut the glass fiber cloth according to the set size of the fragile cover. The main structure, that is, the material used for the frame 1 and the ejection body 4 is glass fiber two-way twill cloth;

[0021] 3) Configure epoxy resin glue;

[0022] 4) Lay layer by layer according to the laying order of [(0 / 90)(±45)(0 / 90)(±45)(0 / 90)(±45)(0 / 90)], and make each layer The glue penetrates the fiber cloth evenly;

[0023] 5) After curing at room temperature for 24 hours, heat treatment at 50°C for 3 hours, and demoulding after cooling;

[0024] 6) Divide the fragile cover prefabricated parts at the height of the separation area, leaving the conjoined area 3 undivided. The length of the conjoined area 3 is 1 / 12~1 / 8 of the 4th circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com