Shunting type discarding flow filter device

A waste flow filtration and split flow technology, which is applied in water supply equipment, grease/oily substance/suspended matter removal devices, water/sludge/sewage treatment, etc., can solve the problems of troublesome sediment removal and high cost of use, and achieve low cost Low, reduced impact, easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

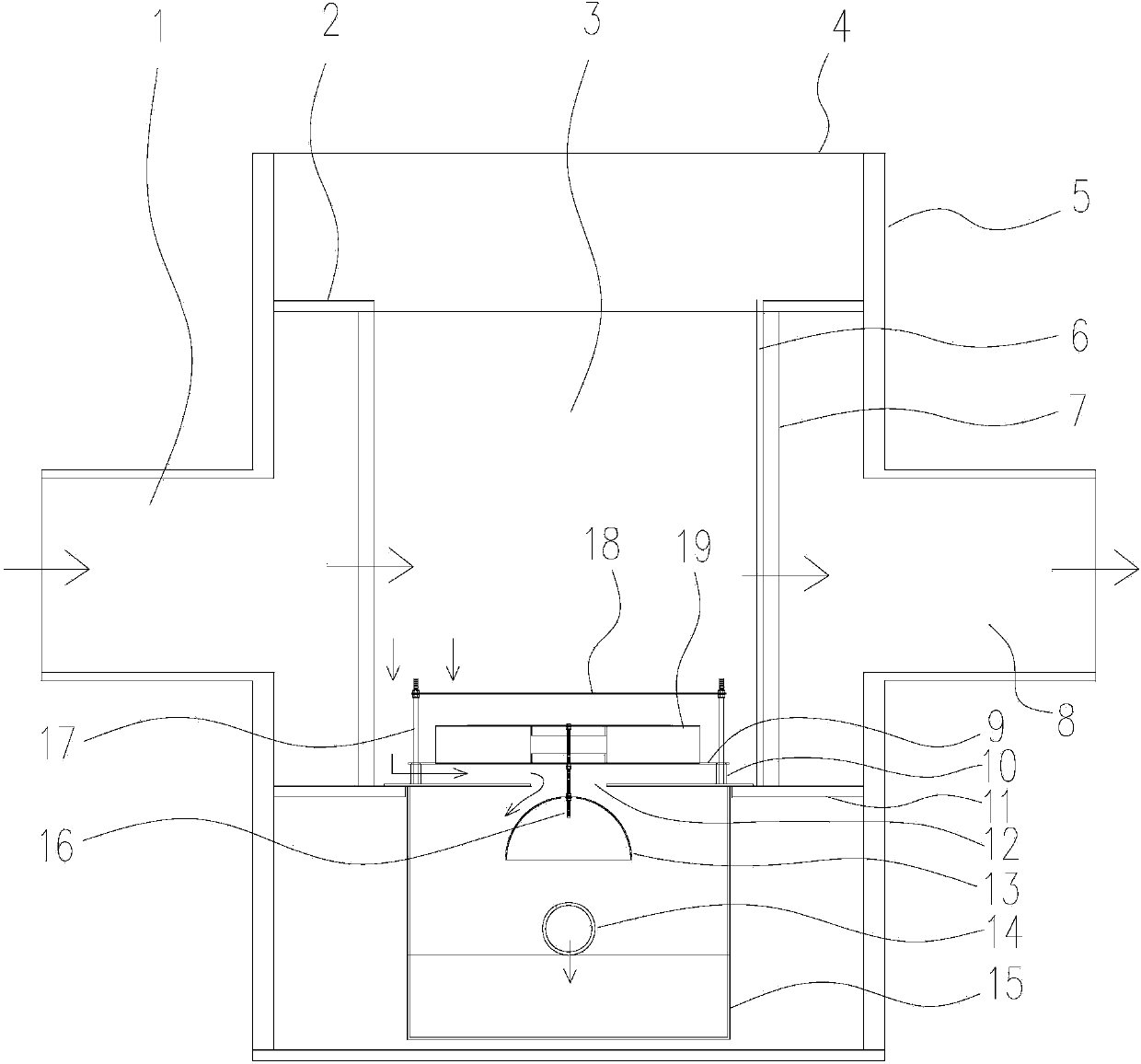

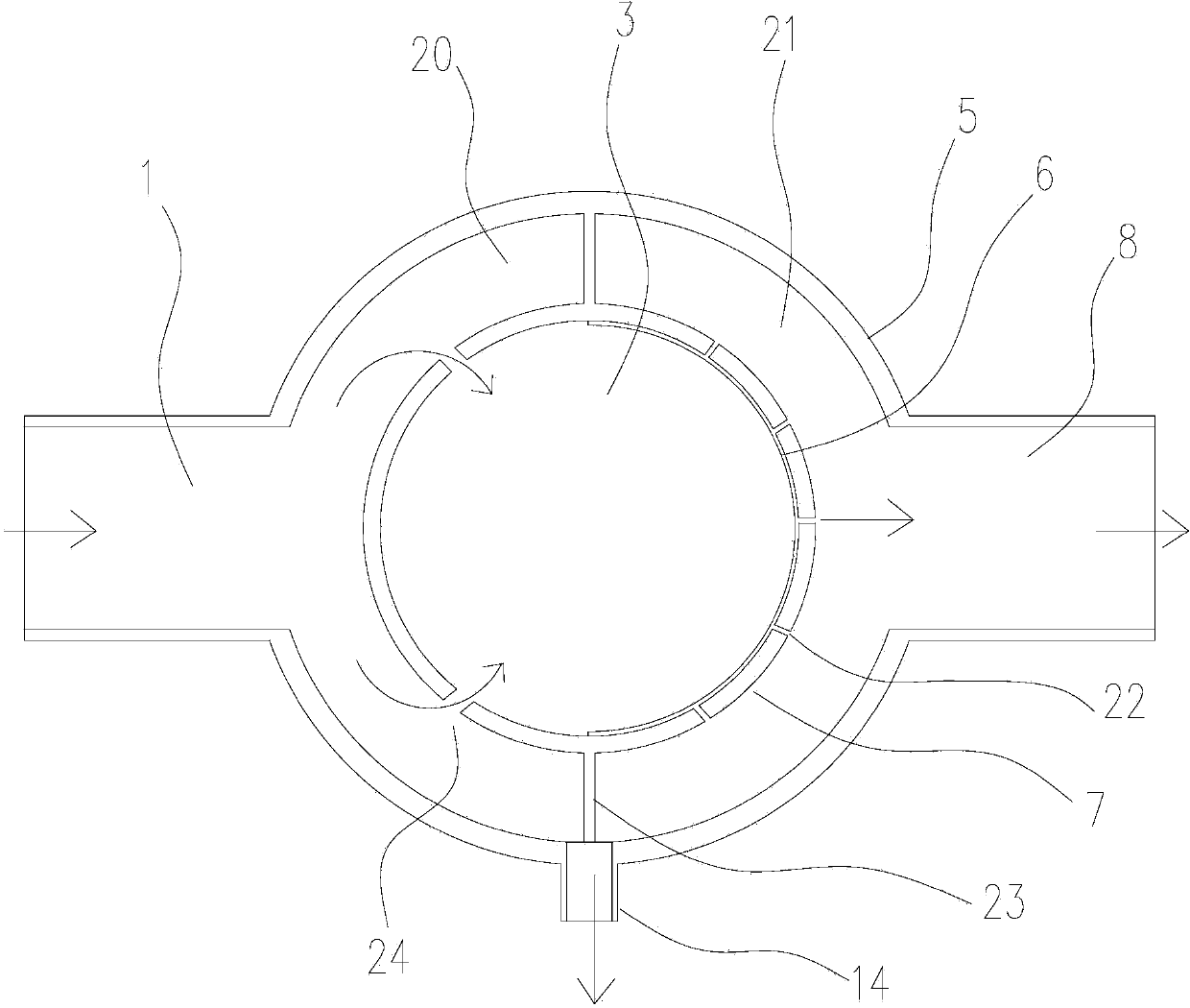

[0020] Such as figure 1 and figure 2 A shunt type discarding filter device shown includes an outer cylinder 5, an inner cylinder 7, a hanging cylinder 15 and a float valve 19, and the inner cylinder 7 is welded and fixed on the inner wall of the outer cylinder 5 through the upper partition 2 and the lower partition 11 , the upper partition 2 can prevent unfiltered rainwater from overflowing into the outer cavity, the lower partition 11 can place the hanging tube 15, the inner tube 7 and the outer tube 5 can be made of plastic materials, such as PE plastic or UPVC plastic, and the outer tube The two sides of 5 are provided with water inlet 1 and water outlet 8, and the water inlet 1 and water outlet 8 are connected with the outer cylinder 5 in a detachable manner such as threaded way, and the water inlet is connected to the sewage interception equipment, and the rainwater passes through the sewage interception equipment. The water inlet enters, and the water outlet 8 is conne...

Embodiment 2

[0023]The difference between this embodiment and Embodiment 1 is that the top of the stabilizing bar 17 is fixed with a steady flow plate 18, and the steady flow plate 18 is located above the float valve 19, the two are not in direct contact, the steady flow plate can be circular or For other shapes, as long as it is not smaller than the float valve, the rainwater falling down from both sides will not directly hit the light float valve below, effectively stabilizing the float valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com