Preparation method and application of C3N4@Ag3PO4/PDA@PVDF bionic composite catalytic membrane

A C3N4, catalytic membrane technology, used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation and recovery of photocatalysts, short life, etc. Excellent separation stability, the effect of solving difficult separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1C 3 N 4 @Ag 3 PO 4 Preparation of / PDA@PVDF biomimetic composite catalytic membrane

[0032] (1) Graphite carbon nitride (g-C 3 N 4 ) preparation

[0033] g-C 3 N 4 The preparation adopts the method of thermally polymerizing melamine: weigh 20 g of melamine in a semi-closed crucible, place it in a drying oven at 80° C. for 48 hours, and then transfer the crucible to a temperature-programmed tube furnace. Heat the temperature-programmed tube furnace at a heating rate of 2.3°C / min to 550°C and keep it warm for 4 hours; after cooling down to room temperature naturally, take it out and grind it into powder with a mortar for later use;

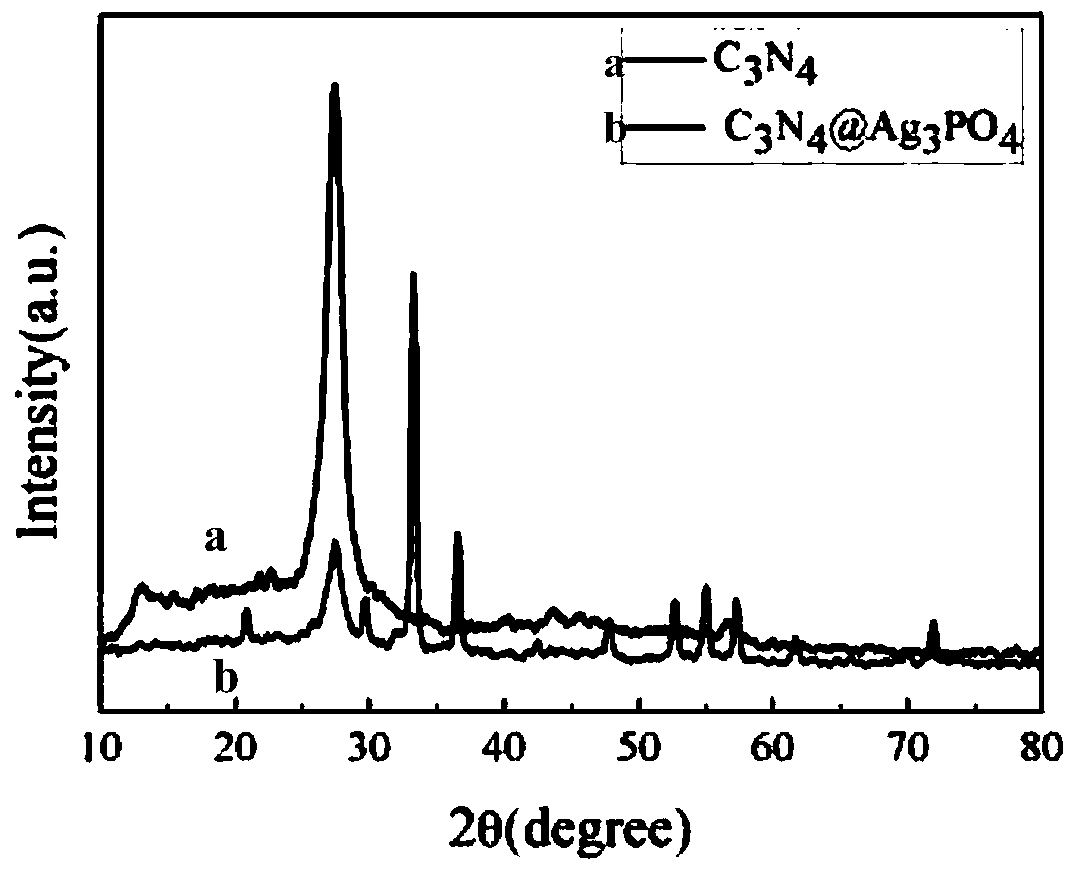

[0034] (2) Binary compound semiconductor materials (C3N4@Ag 3 PO 4 ) preparation

[0035] Weigh 33.97mg AgNO 3 Solids and 80mg g-C 3 N 4 The powder was dissolved in 100mL deionized water, stirred magnetically for 1h to obtain mixed solution A, and 50mL 0.507g / L sodium phosphate solution (Na 3 PO 4 ) was added dropwis...

Embodiment 2

[0045] Example 2C 3 N 4 @Ag 3 PO 4 Preparation of / PDA@PVDF biomimetic composite catalytic membrane

[0046] (1) Graphite carbon nitride (g-C 3 N 4) preparation of

[0047] g-C 3 N 4 The preparation adopts the method of thermally polymerizing melamine: weigh 20 g of melamine in a semi-closed crucible, place it in a drying oven at 80° C. for 48 hours, and then transfer the crucible to a temperature-programmed tube furnace. Heat the temperature-programmed tube furnace at a heating rate of 2.3°C / min to 550°C and keep it warm for 4 hours; after cooling down to room temperature naturally, take it out and grind it into powder with a mortar for later use;

[0048] (2) Binary compound semiconductor materials (C 3 N 4 @Ag 3 PO 4 ) preparation

[0049] Weigh 16.985mg AgNO 3 Solids and 80mg g-C 3 N 4 The powder was dissolved in 100mL deionized water, stirred magnetically for 1h to obtain mixed solution A, and 50mL 0.2535g / L sodium phosphate solution (Na 3 PO 4 ) was add...

Embodiment 3

[0059] Example 3C 3 N 4 @Ag 3 PO 4 Preparation of / PDA@PVDF biomimetic composite catalytic membrane

[0060] (1) Graphite carbon nitride (g-C 3 N 4 ) preparation

[0061] g-C 3 N 4 The preparation adopts the method of thermally polymerizing melamine: weigh 20 g of melamine in a semi-closed crucible, place it in a drying oven at 80° C. for 48 hours, and then transfer the crucible to a temperature-programmed tube furnace. Heat the temperature-programmed tube furnace at a heating rate of 2.3°C / min to 550°C and keep it warm for 4 hours; after cooling down to room temperature naturally, take it out and grind it into powder with a mortar for later use;

[0062] (2) Binary compound semiconductor materials (C 3 N 4 @Ag 3 PO 4 ) preparation

[0063] Weigh 67.94mg AgNO 3 Solids and 80mg g-C 3 N 4 The powder was dissolved in 100mL deionized water, stirred magnetically for 1h to obtain mixed solution A, and 50mL 1.014g / L sodium phosphate solution (Na 3 PO 4 ) was added d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com