Graphene oxide/isostearic acid composite separation membrane and its preparation method and application

A technology of isostearic acid and graphene, which is applied in the field of graphene oxide/isostearic acid composite separation membrane and its preparation, can solve the problem of many factors affecting the separation of oil-water emulsion by graphene oxide composite membrane, graphene oxide film mechanical Unstable performance, composite membrane rejection rate, low water flux and other problems, to achieve the effect of excellent separation stability and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

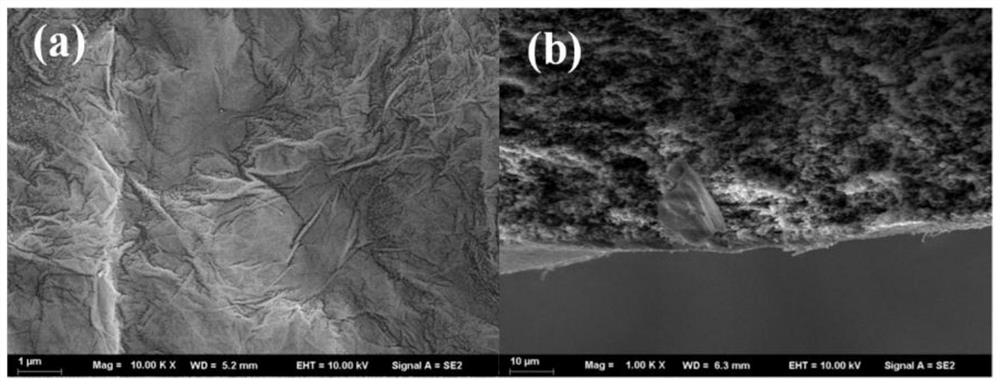

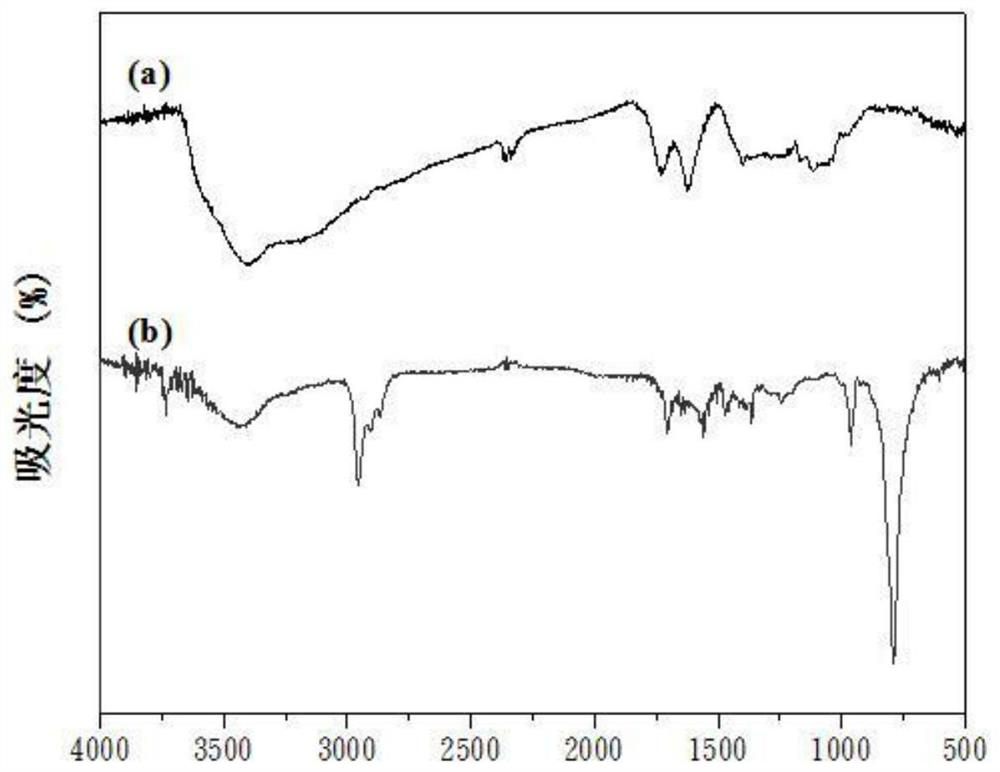

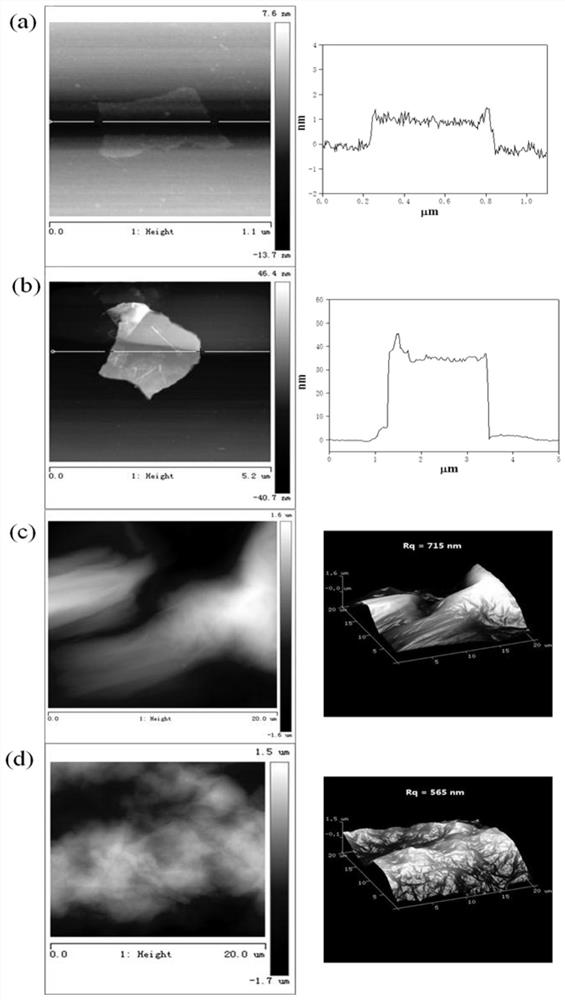

[0024] (1) Preparation of graphene oxide / isostearic acid composite:

[0025] Take 100mg of graphene oxide and dissolve in 50mg of absolute ethanol to obtain mixed solution 1; then take 100mg of isostearic acid and dissolve in 50mg of absolute ethanol to obtain mixed solution 2; combine mixed solution 1 and mixed solution 2 The mixture was mixed uniformly by ultrasonic to obtain the mixture 3 and sealed with plastic wrap; the mixture 3 was placed at 70°C and continuously stirred in a water bath to heat and react for 10 hours, and then the obtained reaction solution was vacuum dried at 80°C for 12 hours to evaporate the ethanol. The graphene oxide / isostearic acid composite is obtained.

[0026] (2) Preparation of graphene oxide / isostearic acid composite separation membrane:

[0027] In a 50mL beaker, take 5mg of graphene oxide / isostearic acid complex (GO-ISA nanocomposite) and dissolve it in 30mL of deionized water, magnetically stir for 20min, and ultrasonic for 20min to obtain 30mL ...

Embodiment 2

[0029] (1) Preparation of graphene oxide / isostearic acid composite:

[0030] Take 50mg of graphene oxide and dissolve in 50mg of absolute ethanol to obtain mixed solution 1; then take 100mg of isostearic acid and dissolve in 50mg of absolute ethanol to obtain mixed solution 2; combine mixed solution 1 and mixed solution 2 The mixture was mixed uniformly by ultrasonic to obtain the mixture 3 and sealed with plastic wrap; the mixture 3 was placed in a water bath with continuous stirring at 70°C for 10 hours, and then the resulting reaction solution was vacuum dried at 80°C for 12 hours to evaporate the ethanol. The graphene oxide / isostearic acid composite is obtained.

[0031] (2) Preparation of graphene oxide / isostearic acid composite separation membrane:

[0032] In a 50mL beaker, take 10mg of graphene oxide / isostearic acid complex (GO-ISA nanocomposite) and dissolve it in 20mL of deionized water, magnetically stir for 30min, and ultrasonic for 30min to obtain 20mL of mixed solution...

Embodiment 3

[0037] (1) Preparation of graphene oxide / isostearic acid composite:

[0038] Take 50mg of graphene oxide and dissolve in 50mg of absolute ethanol solution to obtain mixture 1; then respectively take 150mg of isostearic acid and dissolve in 50mg of absolute ethanol to obtain mixture 2; combine mixture 1 and mixture 2 The mixture was mixed uniformly by ultrasonic to obtain the mixture 3 and sealed with plastic wrap; the mixture 3 was placed in a water bath with continuous stirring at 70°C for 10 hours, and then the resulting reaction solution was vacuum dried at 80°C for 12 hours to evaporate the ethanol. The graphene oxide / isostearic acid composite is obtained.

[0039] (2) Preparation of graphene oxide / isostearic acid composite separation membrane:

[0040] In a 50mL beaker, take 15mg of graphene oxide / isostearic acid complex (GO-ISA nanocomposite) and dissolve it in 10mL of deionized water, magnetically stir for 40min, and ultrasonic for 40min to obtain 10mL of mixed solution 4 (GO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com