Improved oil-water separation device

An oil-water separation device and an improved technology are applied in the field of the improved oil-water separation device and the improved oil-water separation device, which can solve the problems of increased separation difficulty, easily broken oil droplets, and narrow application range, and achieve a compact and good device structure. Compatibility and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] Below in conjunction with accompanying drawing and example, the present invention is described in further detail, and specific implementation is as follows:

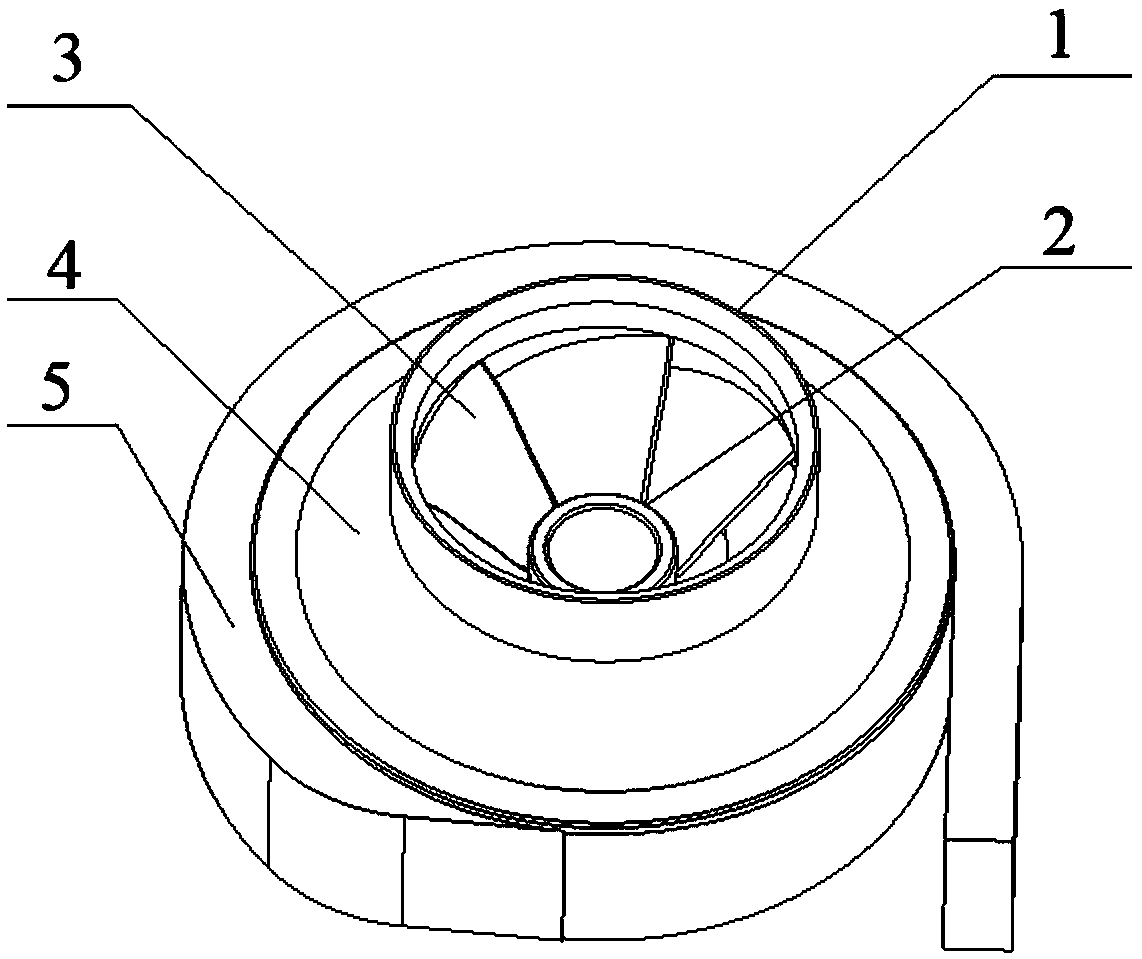

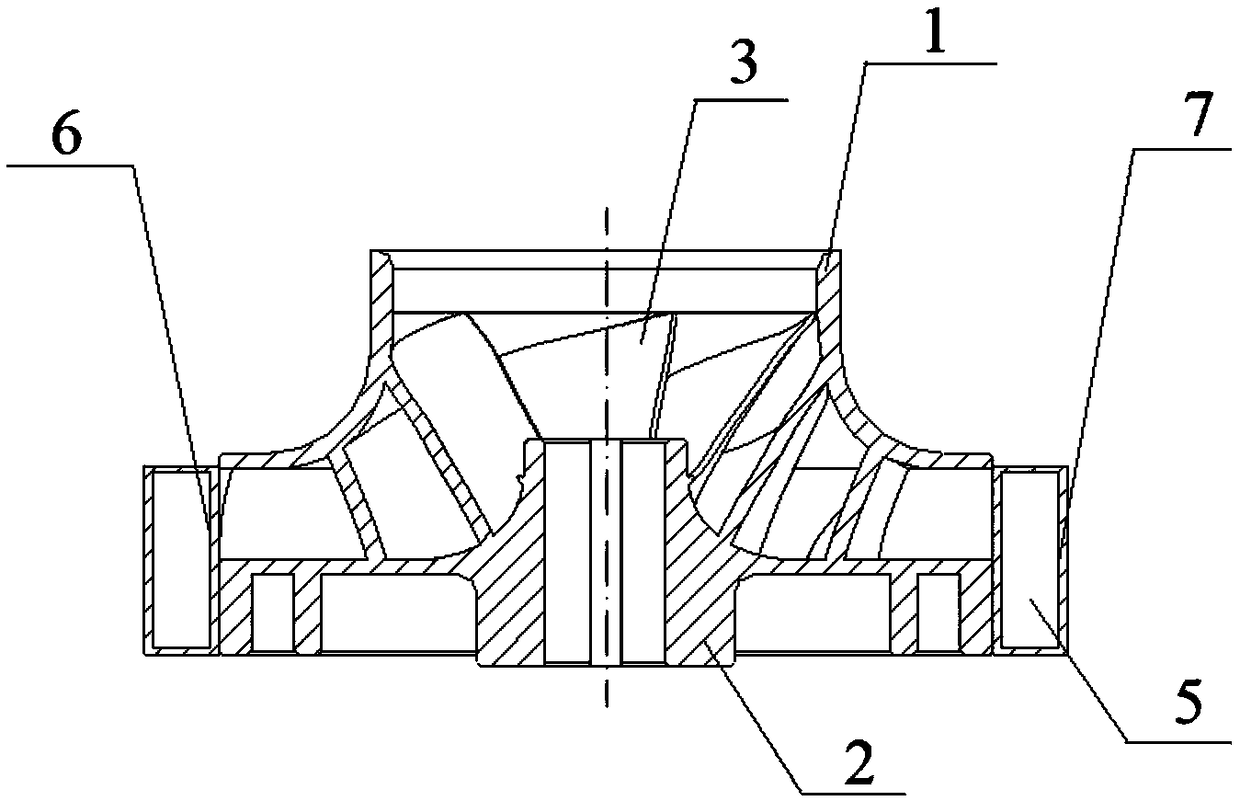

[0021] Such as Figure 1~2 As shown, an improved oil-water separation device includes a mixture inlet 1 , a drive shaft 2 , an impeller 3 , an acceleration zone 4 and a separation zone 5 .

[0022] Among them, the separation zone 5 adopts a spiral pipeline with a rectangular cross-section. Inside the pipeline, the wall near the acceleration zone 4 is an oil-friendly and hydrophobic inner wall 6, and the wall on the side away from the acceleration zone 4 is a hydrophilic-oleophobic outer wall. 7.

[0023] The transmission shaft 2 is located at the center of the device, from which the impeller 3 and the separation area 5 are in turn outward, the impeller 3 is fixedly connected to the outside of the transmission shaft 2, the external motor drives the transmission shaft 2 to drive the impeller 3 to rotate, and a mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com