Blowing type device for recovering cut tobacco in rejected stem slivers

A shredded tobacco recovery device and blowing-type technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the waste of shredded tobacco, increase the production cost of tobacco enterprises, and increase the smoking capacity of cigarette machines. Issues such as the air flow rate of the orifice plate of the wire forming system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

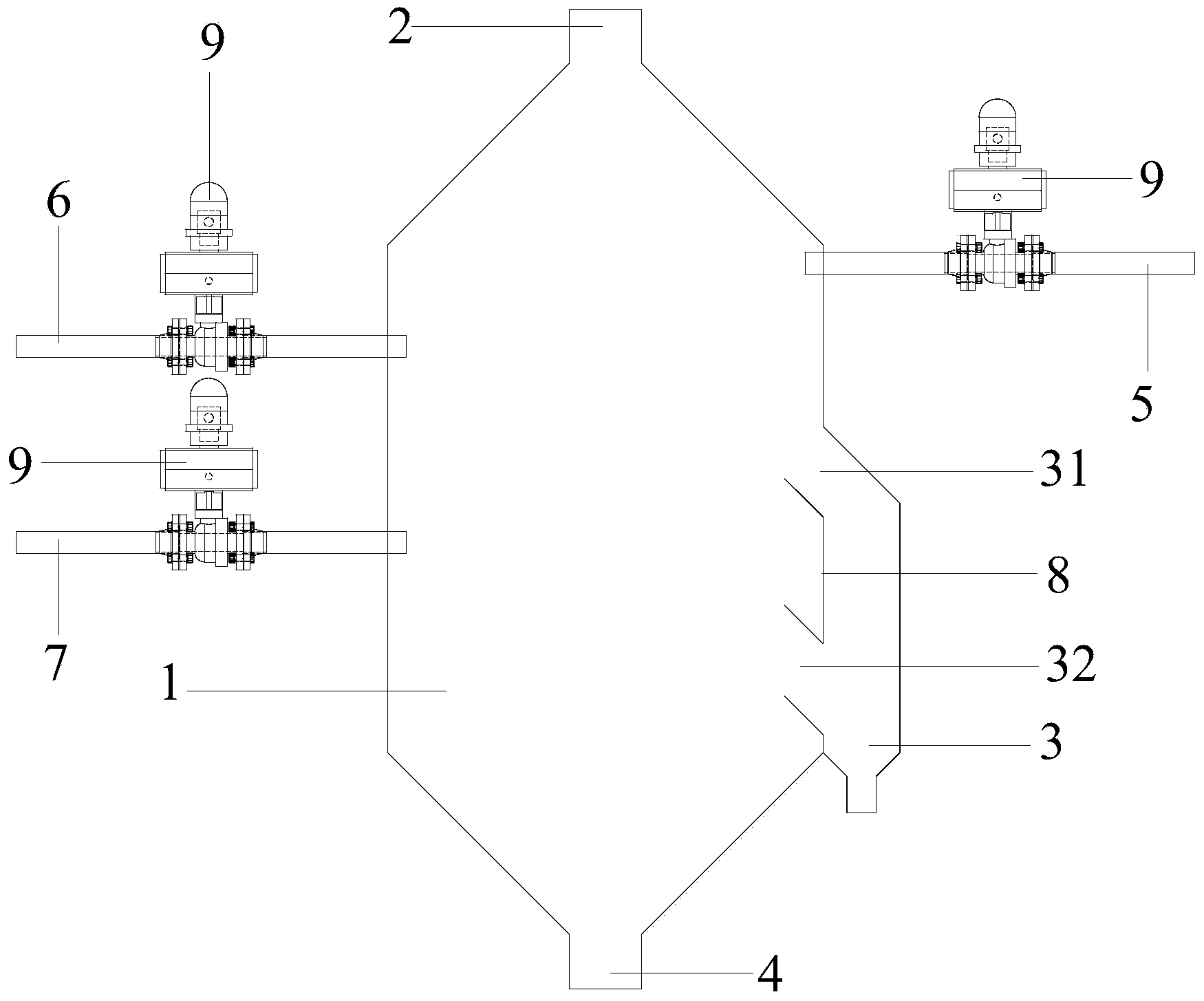

[0021] See figure 1 , which is a schematic structural view of the shredded tobacco recovery device in the blowing-type stem stick rejects according to the embodiment of the present invention.

[0022] The device for recovering shredded tobacco from the ejected stem stick rejects provided by the embodiment of the present invention includes a separation chamber 1. The separation chamber 1 is provided with an inlet 2 for stem pick rejects, an outlet 3 for shredded tobacco, and a discharge port 4 for stem stick rejects. The inlet 2 is arranged on the top of the separation chamber 1, the stem drop opening 4 is arranged on the bottom of the separation chamber 1, the shredded tobacco outlet 3 is arranged in the middle and lower side of the side of the separation chamber 1; the shredded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com