Method for preparing polymer heterogeneous Fenton-like catalyst-polyvinylidene fluoride (PVDF) catalytic membrane

A polymer and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. and other problems, to achieve the effect of simple method, easy operation and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

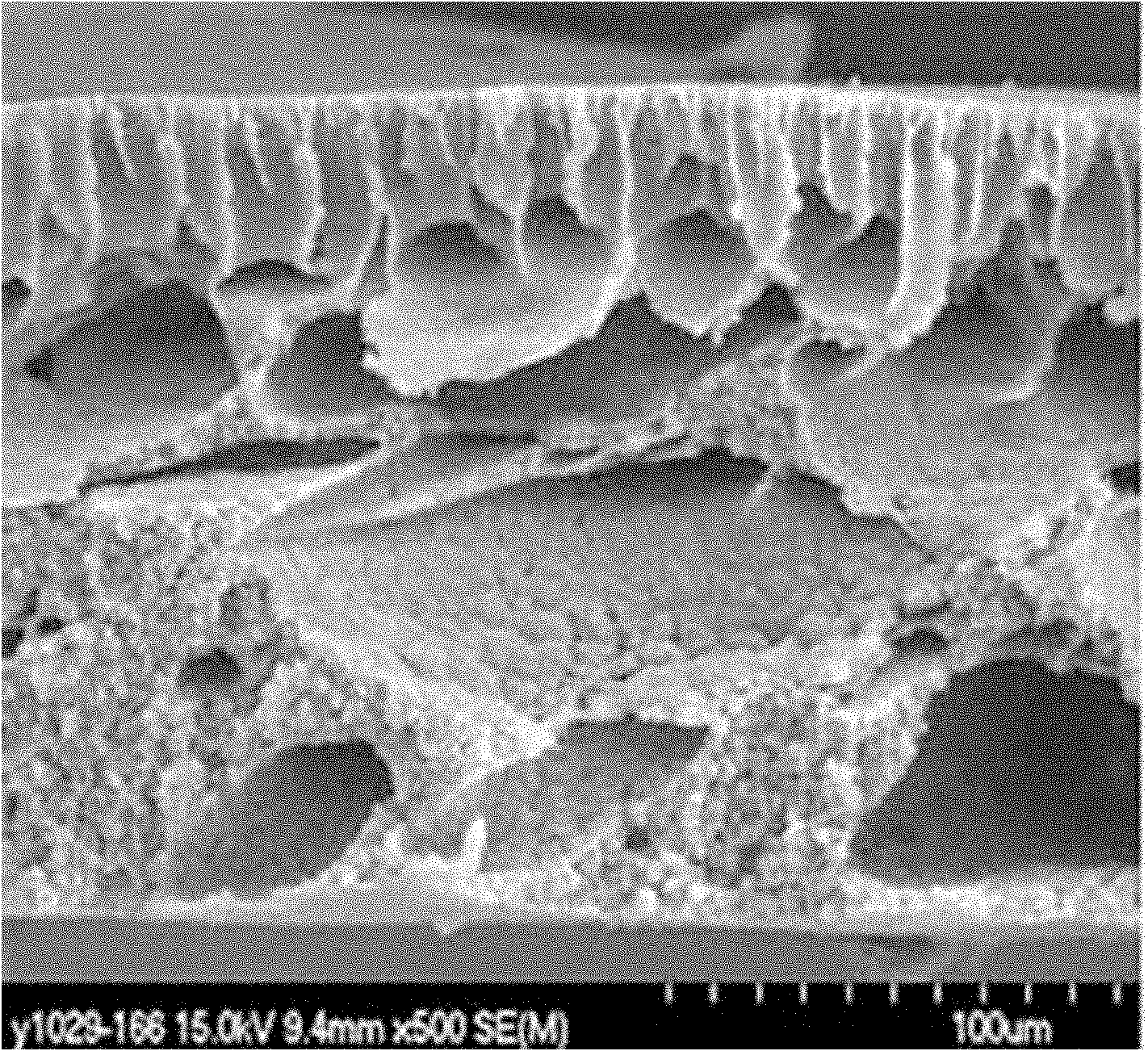

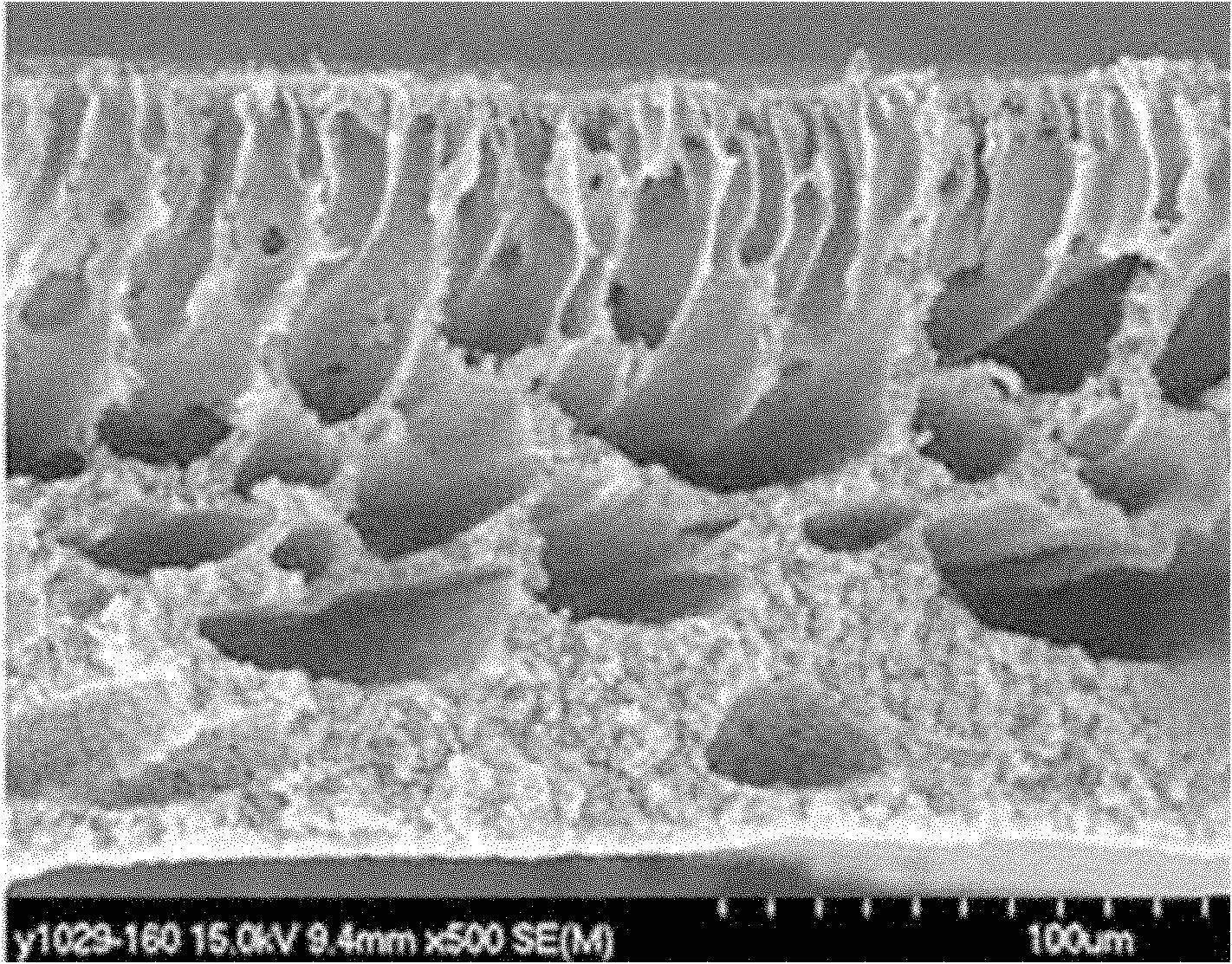

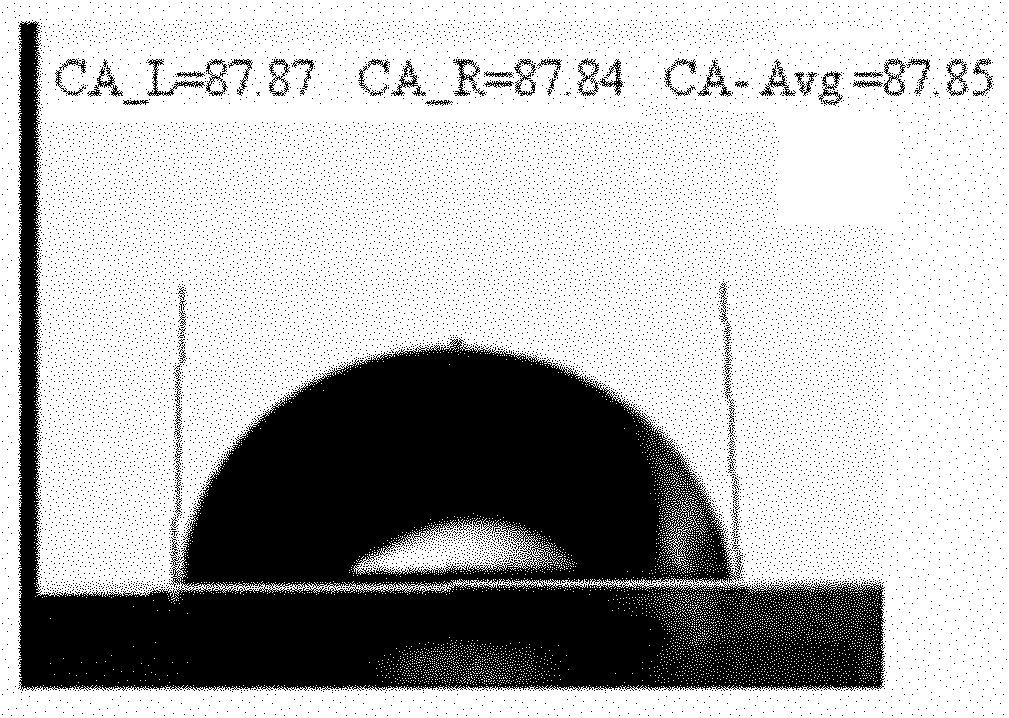

[0008] Specific embodiment one: The preparation method of the polymer heterogeneous Fenton-like catalyst-PVDF catalytic membrane in this embodiment is carried out in the following steps: 1. Weigh 4 to 20 parts of polyvinylidene fluoride, 50 parts by mass, respectively ~90 parts of solvent and 0.1~10 parts of additives are mixed, then stirred at 45℃~60℃ until completely dissolved, kept at constant temperature for 30min~30h at 30℃~55℃, and then scraped the film on a clean glass plate , then immerse in a coagulation bath (distilled water) for 30min to 24h to obtain a PVDF membrane; 2. Put the PVDF membrane prepared in step 1 into an ethanol solution with a volume concentration of 50% to 75% for pretreatment for 5min to 120min, Then treat it with deionized water for 10min to 120min; 3. Put the PVDF membrane treated in step 2 into an alkali solution with a concentration of tetrabutylammonium bromide of 0.1 to 4mg / mL, and then base it at 0°C to 70°C Treat for 5min to 15min, and wash...

specific Embodiment approach 2

[0009] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 8-15 parts of PVDF, 60-80 parts of solvent and 1-8 parts of additives are weighed and mixed according to the ratio of parts by weight. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, 10 parts of PVDF, 70 parts of solvent and 5 parts of additives are weighed and mixed according to the ratio of parts by weight. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com