Automatic spraying device for preparing fuel cell membrane electrode

A fuel cell membrane, automatic spraying technology, applied in the direction of injection device, device for coating liquid on the surface, coating, etc., to achieve the effects of improving swelling deformation, improving sedimentation and agglomeration, and improving swelling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

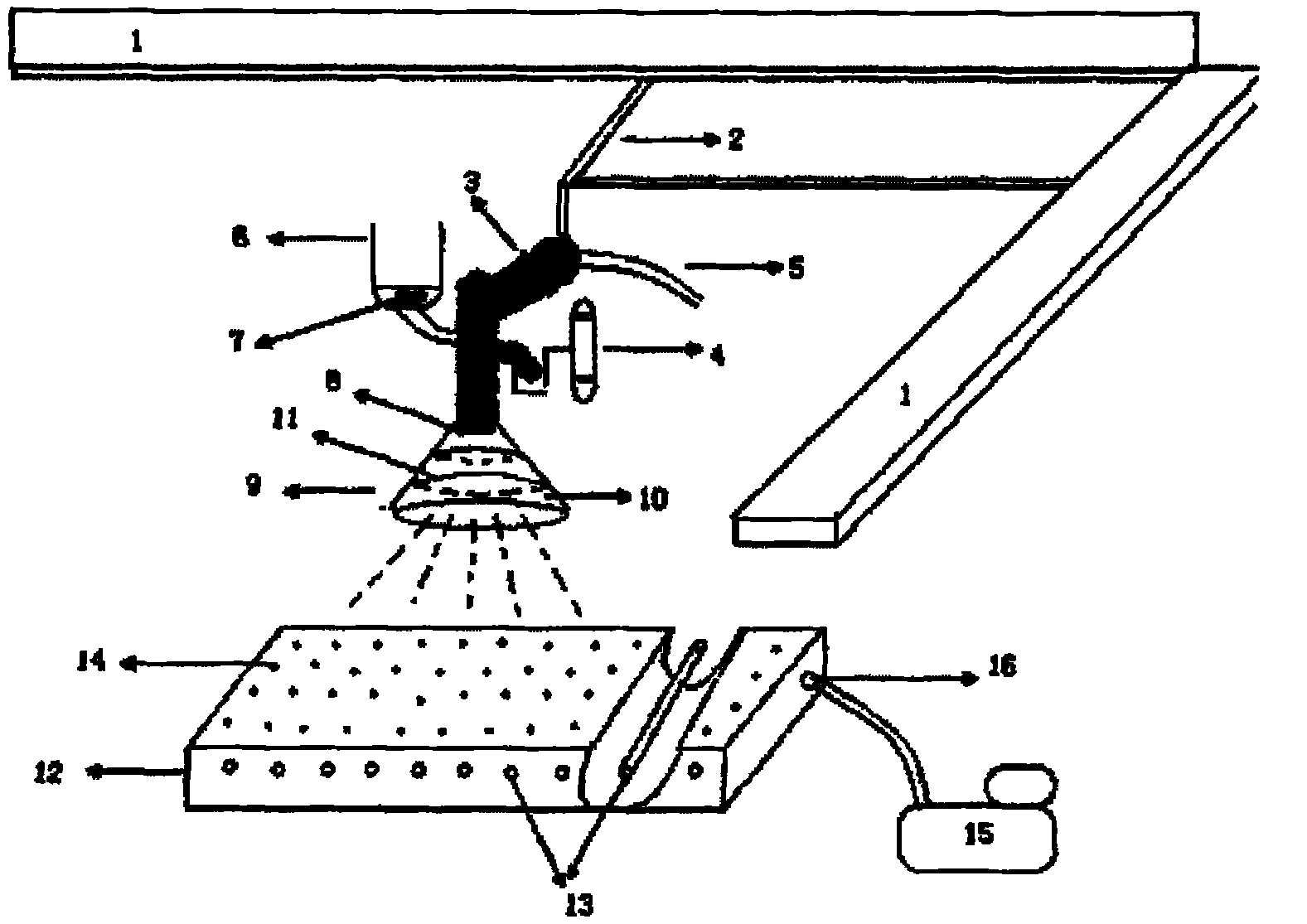

[0041] Such as image 3 As shown, an automatic spraying machine for preparing fuel cell membrane electrodes includes a workbench and a spray gun. On the basis of the existing HY-5S automatic sprayer, the workbench, spray gun, and liquid storage hopper are newly improved;

[0042] The workbench is a vacuum heating platform, which is a hollow box, and an electric heating wire is arranged in the box. The box is connected to the vacuum pump through a pipeline, and the upper surface is flat. orifice in the body cavity;

[0043] The spray gun is connected with the liquid storage hopper of the spraying machine through a pipeline, and an ultrasonic oscillator is arranged at the bottom of the hopper; an umbrella-shaped heating mantle is arranged at the nozzle of the spray gun, and the nozzle extends into the umbrella body from the top of the umbrella-shaped heating mantle Inside, the material liquid sprayed from the nozzle is heated, and the umbrella-shaped heating cover is composed o...

Embodiment 2

[0048] The difference from Example 1 is that the distance between the vacuum holes is set to 1 cm, the distance between the spray gun and the table is 5 cm, and the spraying speed is 3 cm / s.

Embodiment 3

[0050] The difference from Example 1 is that the temperature of the hot stage and the temperature of the heating mantle in the spraying environment are set to 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com