Battery size measurement method, device and equipment and storage medium

A measurement method and battery technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as liquid leakage, battery swelling deformation, battery spontaneous combustion, etc., and achieve the effect of improving the quality of the module and avoiding swelling and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

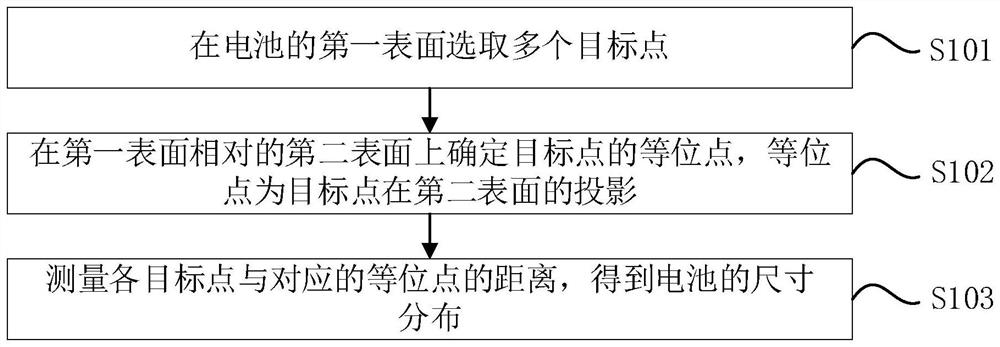

[0063] figure 1 It is a flow chart of a battery size measurement method provided by Embodiment 1 of the present invention. This embodiment is applicable to the case where the surface of the battery has unevenness and undulations. The method can be performed by the battery size measurement device provided by the embodiment of the present invention. , the device can be implemented by software and / or hardware, and is usually configured in computer equipment, such asfigure 1 As shown, the method specifically includes the following steps:

[0064] S101. Select multiple target points on the first surface of the battery.

[0065] In the embodiment of the present invention, the battery may be a soft-pack lithium battery, and the soft-pack lithium battery is a liquid lithium-ion battery covered with a polymer shell. In terms of structure, it is packaged with aluminum-plastic film. In the event of a safety hazard, the soft-pack battery will at most explode and burst, and eventually cat...

Embodiment 2

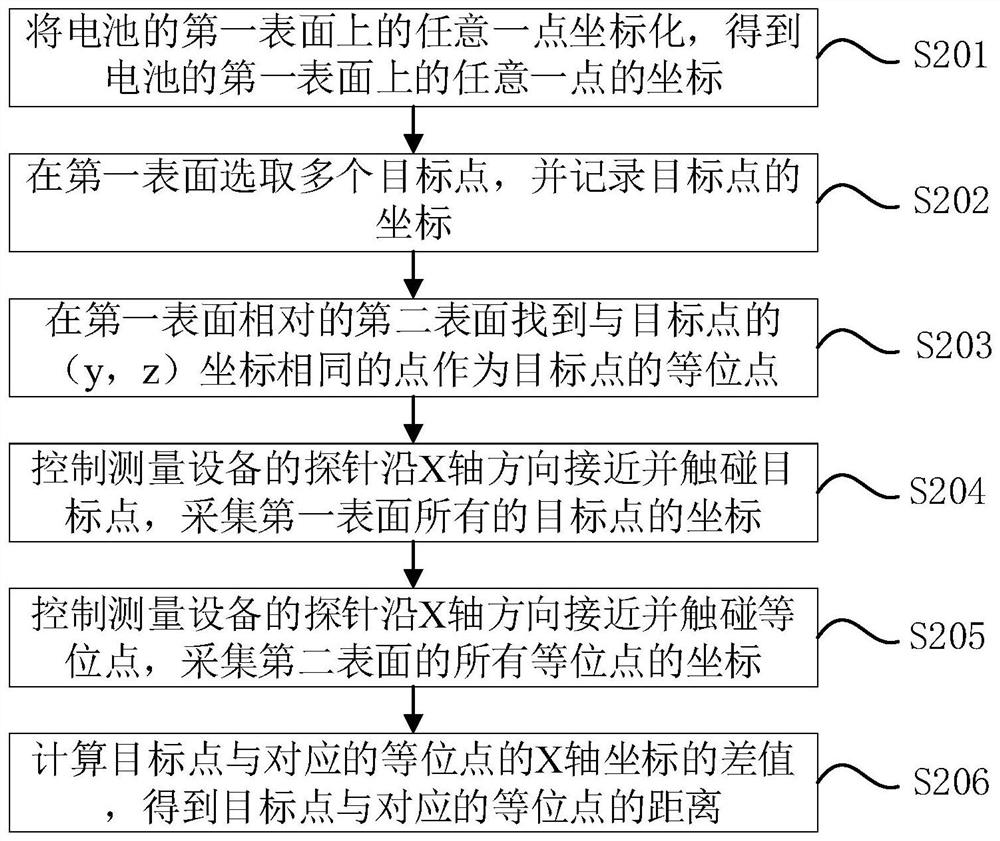

[0074] Figure 2A It is a flow chart of a battery size measurement method provided by Embodiment 2 of the present invention. This embodiment is further refined on the basis of the above-mentioned Embodiment 1, and describes in detail the specific process of each step in the battery size measurement method, as shown in Figure 2A As shown, the method includes:

[0075] S201. Coordinate any point on the first surface of the battery to obtain the coordinates of any point on the first surface of the battery.

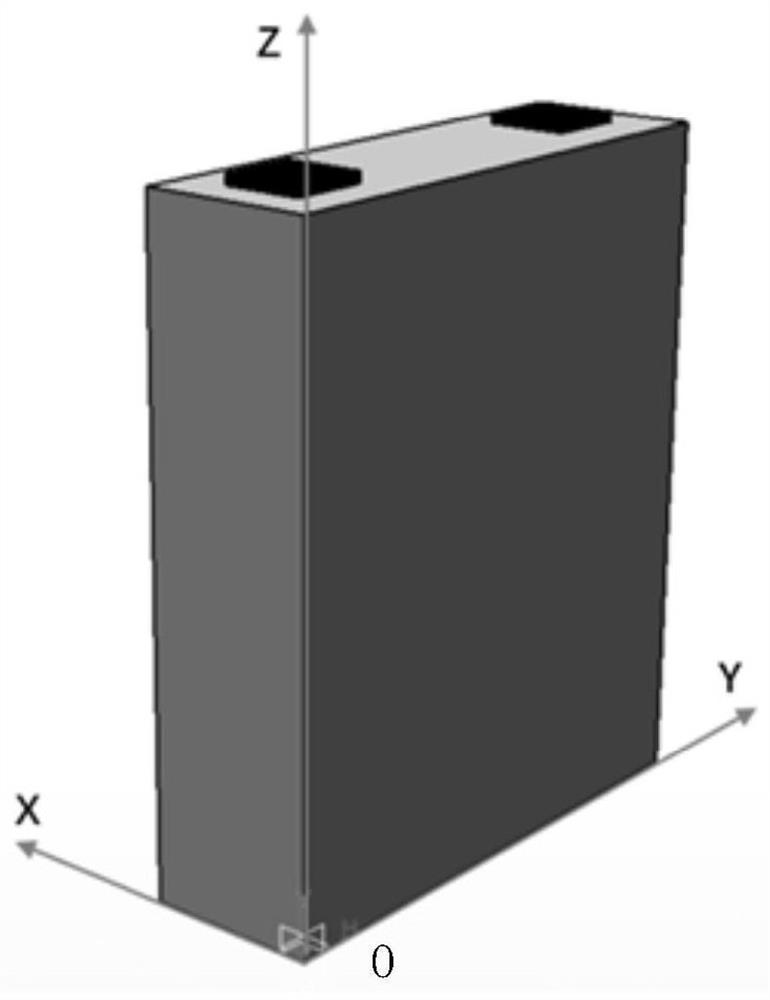

[0076] In the embodiment of the present invention, a space rectangular coordinate system is established, and any point on the first surface of the battery is coordinateized to obtain the coordinates of any point on the first surface of the battery.

[0077] In some embodiments of the present invention, the process of establishing a space Cartesian coordinate system is as follows:

[0078] 1. Select a local area on the first surface of the battery whose flatness is greater ...

Embodiment 3

[0104] image 3 A schematic structural diagram of a battery size measuring device provided in Embodiment 3 of the present invention, as shown in image 3 As shown, the device includes:

[0105] A target point selection module 301, configured to select a plurality of target points on the first surface of the battery;

[0106] an isotropic point determining module 302, configured to determine the isotropic point of the target point on a second surface opposite to the first surface, the isostatic point being a projection of the target point on the second surface;

[0107] The measurement module 303 is configured to measure the distance between each target point and the corresponding equipotential point to obtain the size distribution of the battery.

[0108] In some embodiments of the present invention, the target point selection module 301 includes:

[0109] A coordinate submodule, configured to coordinate any point on the first surface of the battery to obtain the coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com