Bi2WO6 photocatalysis membrane loaded by base with high specific surface, method and application thereof

A technology of high specific surface area and photocatalytic film, applied in chemical instruments and methods, applications, separation methods, etc., can solve problems affecting the effective area of catalysts, unfavorable environmental purification applications, small specific surface area of substrates, etc., and achieve good cycle stability Sexuality, low production cost, easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Bi 2 WO 6 Using Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O (analytical pure) is synthesized as a raw material, and according to the stoichiometric ratio, weigh 0.97gBi(NO 3 ) 3 ·5H 2 O and 0.329gNa 2 WO 4 2H 2 O was dissolved in ethylene glycol respectively, and the above two solutions were mixed uniformly to obtain a clear solution, which was then transferred to a hydrothermal kettle and heated at 160°C for 16 hours. After the reaction, the obtained product was centrifuged, washed and then dried at 60° C. for 4 hours. Dip the clean stainless steel wire mesh in the evenly dispersed Bi 2 WO 6 In the ethanol suspension of nanopowders, the Bi 2 WO 6 Membrane, after drying, repeat the number of pulls until about 20gm on the load -2 Bi 2 WO 6 , and finally heat-treated at 200 °C to prepare the stainless steel mesh-loaded Bi 2 WO 6 photocatalytic film.

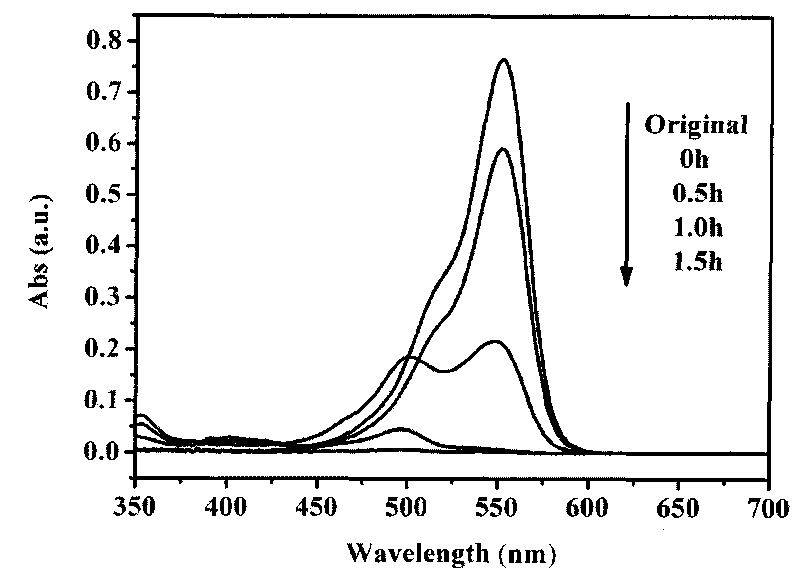

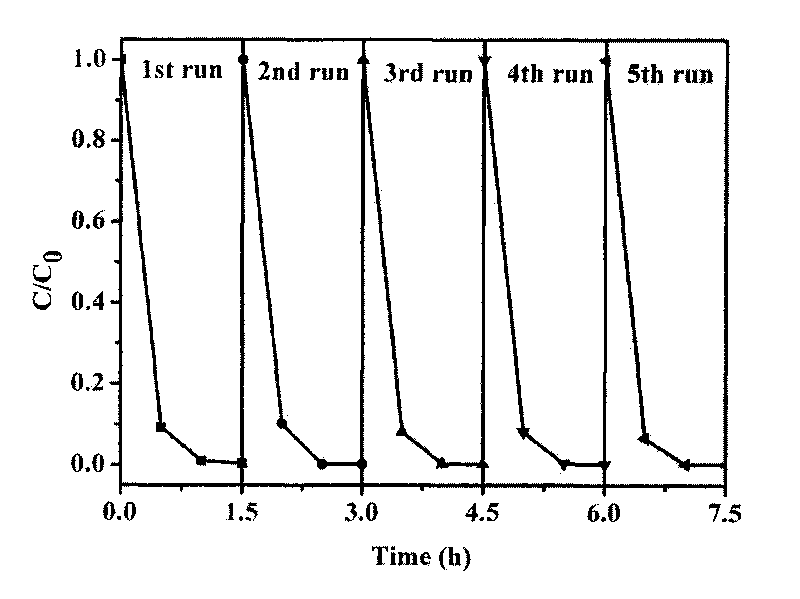

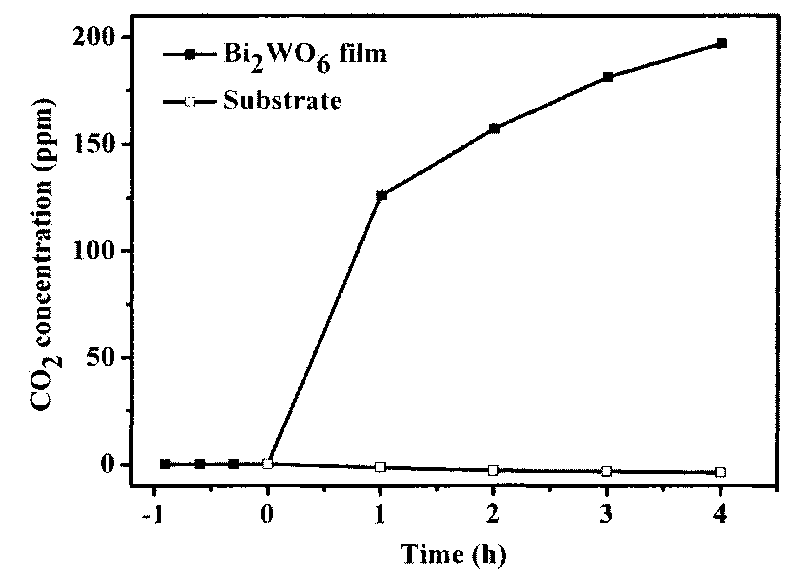

[0026] In order to study the performance of the prepared photocatalytic film in the application of sewa...

Embodiment 2

[0030] Adopt the method identical with embodiment 1, by stoichiometric ratio with Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O (analytically pure) is used as raw material, and ethylene glycol is used as solvent to synthesize Bi 2 WO 6 , and the Bi 2 WO 6 The nanopowder is loaded on the nickel foam substrate. After comparative experiments, the obtained Bi 2 WO 6 The film degraded 90% of RhB (such as Figure 4 shown).

Embodiment 3

[0032] Adopt the method identical with embodiment 1, by stoichiometric ratio with Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O (analytically pure) is used as raw material, and ethylene glycol is used as solvent to synthesize Bi 2 WO 6 , and the Bi 2 WO 6 Nanopowder loaded on porous TiO 2 on a ceramic sheet. After comparative experiments, the obtained Bi 2 WO 6 The film degraded 95% of RhB after 4 hours of irradiation with visible light with wavelength λ > 420 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com