Application method of MnxCe(1-x)O2 nanoparticles

An application method and nanoparticle technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrical components, etc., can solve the problems of high cost, low catalytic activity of catalysts, complex synthesis process, etc. Achieve good electrochemical performance, high electrocatalytic activity, and improve energy density and power performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

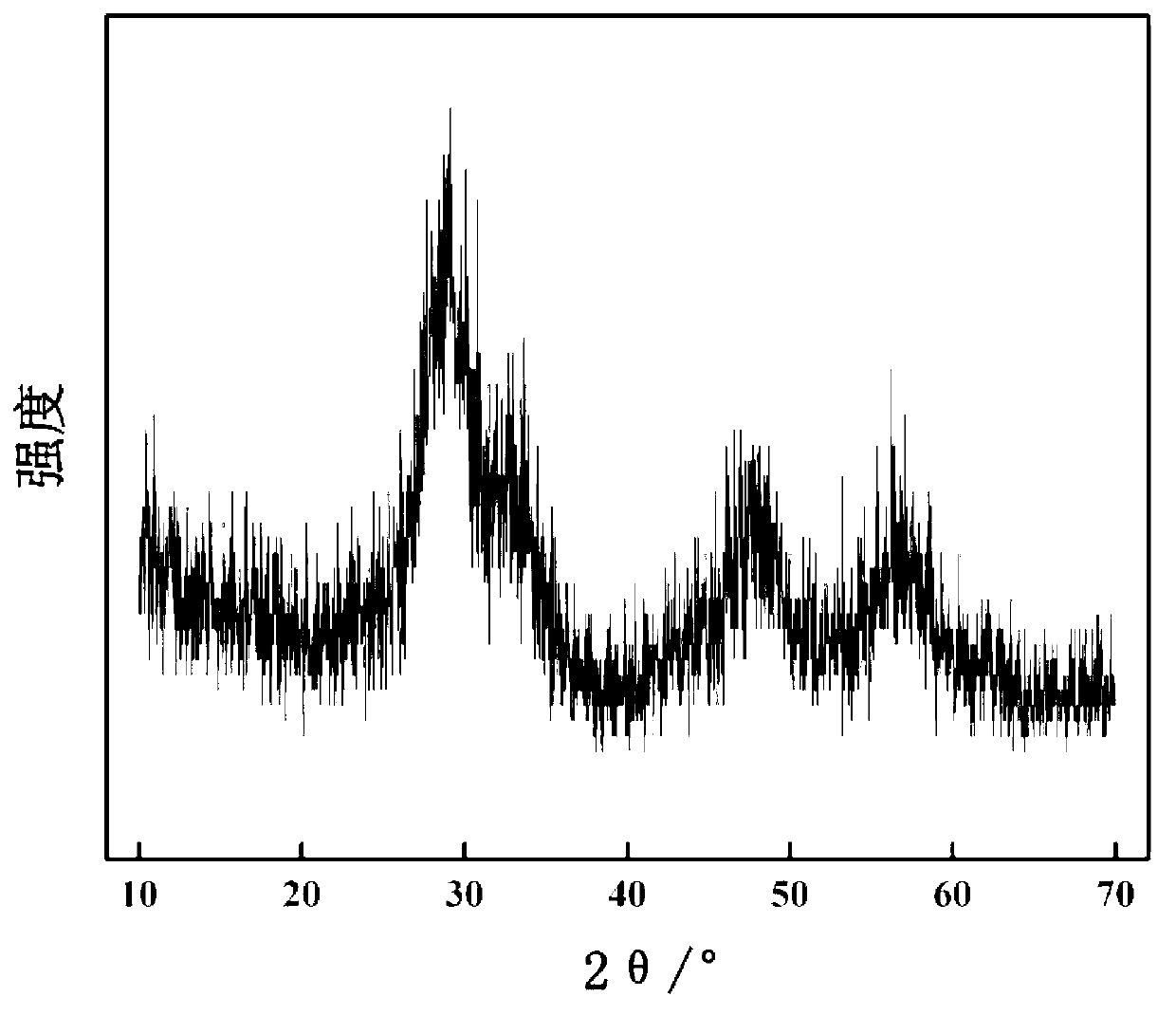

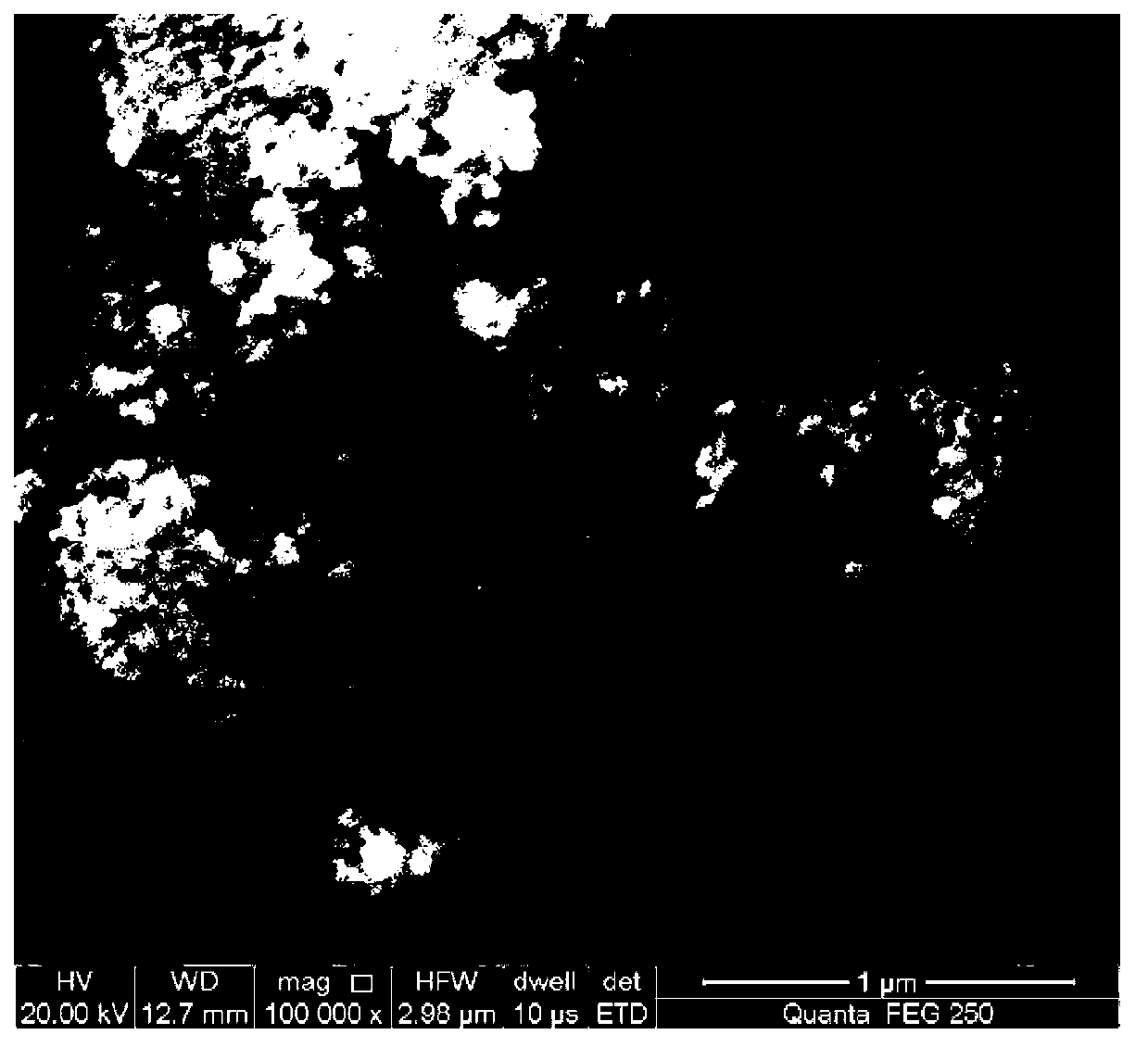

[0030] According to the material molar ratio Mn: Ce=1:2, weigh 0.6g of 50% manganese nitrate solution, 0.13g of potassium permanganate, and 1.74g of cerium nitrate hexahydrate, dissolve these three compounds in deionized water, and transfer to 50 In a water bath at ℃, add 2 mol / L KOH drop by drop under magnetic stirring until the pH reaches 10, and then continue to age for 2 hours. After cooling, filter under reduced pressure, wash to obtain the precursor, and vacuum dry at 60 ℃ for 24 hours. Calcined at 350°C for 5 hours in a muffle furnace to obtain the target product. Its crystal structure is shown in figure 1 . It can be seen from the XRD curve that the prepared product belongs to CeO with cubic fluorite structure. 2 , since the radius of manganese ions is smaller than that of cerium particles, manganese ions will be inserted into CeO during the calcination process 2 A solid solution is formed in the crystal lattice, so XRD detection can only find CeO 2 characteristic ...

Embodiment 2

[0033] Weigh 0.6g of 50% manganese nitrate solution and 0.13g of potassium permanganate, without adding cerium nitrate hexahydrate, the product obtained is MnO 2 , Dissolve these two compounds in deionized water, transfer them to a 50°C water bath, add 2mol / L KOH drop by drop under magnetic stirring until the pH reaches 10, continue to age for 2 hours, and filter under reduced pressure after cooling , washed to obtain a precursor, vacuum dried at 60°C for 24 hours, and then calcined in a muffle furnace at 350°C for 5 hours to obtain the target product. The manufacturing process and testing methods of the air electrode are the same as those in Example 1. Image 6 Polarization curves of the air electrode were recorded. It can be seen from the figure that at the polarization potential of -0.55V (vsHg / HgO), the polarization current density reaches 355mA / cm 2 .

Embodiment 3

[0035] Weigh 1.74g of cerium nitrate hexahydrate, without adding manganese nitrate solution and potassium permanganate, the product obtained is CeO 2 , dissolve it in deionized water, transfer it to a 50°C water bath, add 2mol / L KOH drop by drop under magnetic stirring until the pH reaches 10, and continue to age for 2 hours. After cooling, filter under reduced pressure and wash. The precursor was obtained, dried in vacuum at 60°C for 24 hours, and then calcined in a muffle furnace at 350°C for 5 hours to obtain the target product. The manufacturing process and testing methods of the air electrode are the same as those in Example 1. Image 6 Polarization curves of the air electrode were recorded. It can be seen from the figure that at the polarization potential of -0.55V (vsHg / HgO), the polarization current density reaches 244mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com