Preparation method and application of fiber composite membrane catalyst

A fiber composite and catalyst technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problems of reduced catalytic performance, easy agglomeration, etc. , to avoid agglomeration, the effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of fiber composite membrane catalyst comprises the following steps:

[0029] 1) Select cotton dissolving pulp, beat and disperse to obtain cellulose pulp with a mass fraction of 4%; add 5ml of 15% sodium hydroxide solution to 1g of cellulose pulp, and carry out alkalization reaction at room temperature, After reacting for 3 hours, add 5ml of 20% sodium chloroacetate solution to carry out etherification reaction at 60°C, react for 4 hours, and finally wash the fiber with absolute ethanol at room temperature until neutral to obtain carboxymethyl fiber;

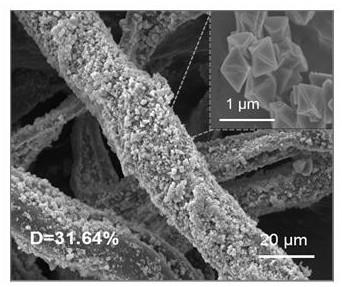

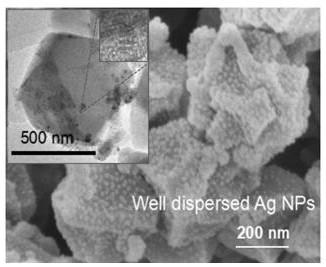

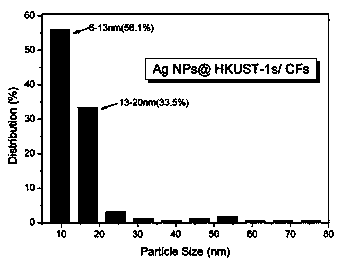

[0030] 2) Prepare two 100ml mixed solutions of N,N-dimethylformamide (DMF), ethanol and water as solution A and solution B, N,N-dimethylformamide (DMF), ethanol and water The volume ratio is 1:1:1; add 2g of copper acetate to solution A, add 1g of trimesic acid to solution B, and stir thoroughly; weigh 2g of carboxymethyl fiber and soak it in solution A for 30min, then Transfer to B solution for 30...

Embodiment 2

[0034] The preparation method of fiber composite membrane catalyst comprises the following steps:

[0035] 1) Select DQP bleached bamboo pulp, and after beating and dispersing, a cellulose pulp with a mass fraction of 6% is obtained; 8ml of a 20% sodium hydroxide solution is added to 0.5g of the pulp, and alkalization is carried out at room temperature. After reacting for 2 hours, add 8ml of sodium chloroacetate solution with a concentration of 25% to carry out etherification reaction at 50°C, react for 3 hours, and finally wash the fibers with absolute ethanol at room temperature until neutral to obtain carboxymethyl fibers;

[0036] 2) Prepare two 100ml DMF, the mixed solutions of ethanol and water are recorded as solution A and solution B, the volume ratio of N,N-dimethylformamide (DMF), ethanol and water is 1:1:1; Add 2g of copper nitrate to solution A, add 1g of terephthalic acid to solution B, and stir thoroughly; weigh 1g of carboxymethyl fiber and soak it in solution A...

Embodiment 3

[0039] The preparation method of fiber composite membrane catalyst comprises the following steps:

[0040] 1) Select hardwood pulp, beat and disperse to obtain cellulose pulp with a mass fraction of 10%; add 10ml of 25% sodium hydroxide solution to 2g of cellulose pulp, and carry out alkalization reaction at room temperature , after reacting for 4 hours, add 10ml of sodium chloroacetate solution with a concentration of 25% to carry out etherification reaction at 40°C, react for 5 hours, and finally wash the fiber with absolute ethanol at room temperature until neutral to obtain carboxymethyl fiber;

[0041] 2) Prepare two 100ml mixtures of N,N-dimethylformamide (DMF), ethanol and water as solution A and solution B, N,N-dimethylformamide (DMF), ethanol and water The volume ratio is 1:1:1; add 2g of copper sulfate to solution A, add 1g of terephthalic acid to solution B, and stir thoroughly; weigh 3g of carboxymethyl fiber and soak it in solution A for 120min, then After transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com