Method for separating high-salt-containing concentrated water by light-assisted catalytic membrane for decoloration

A high-salt, light-assisted technology, which is applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., can solve the difficulty of increasing engineering of equipment stability, increasing the cost of catalyst recycling, ozone Problems such as high investment cost and operating cost, achieve the effect of adding a secondary enhanced catalytic system, avoiding high investment cost and operating cost, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

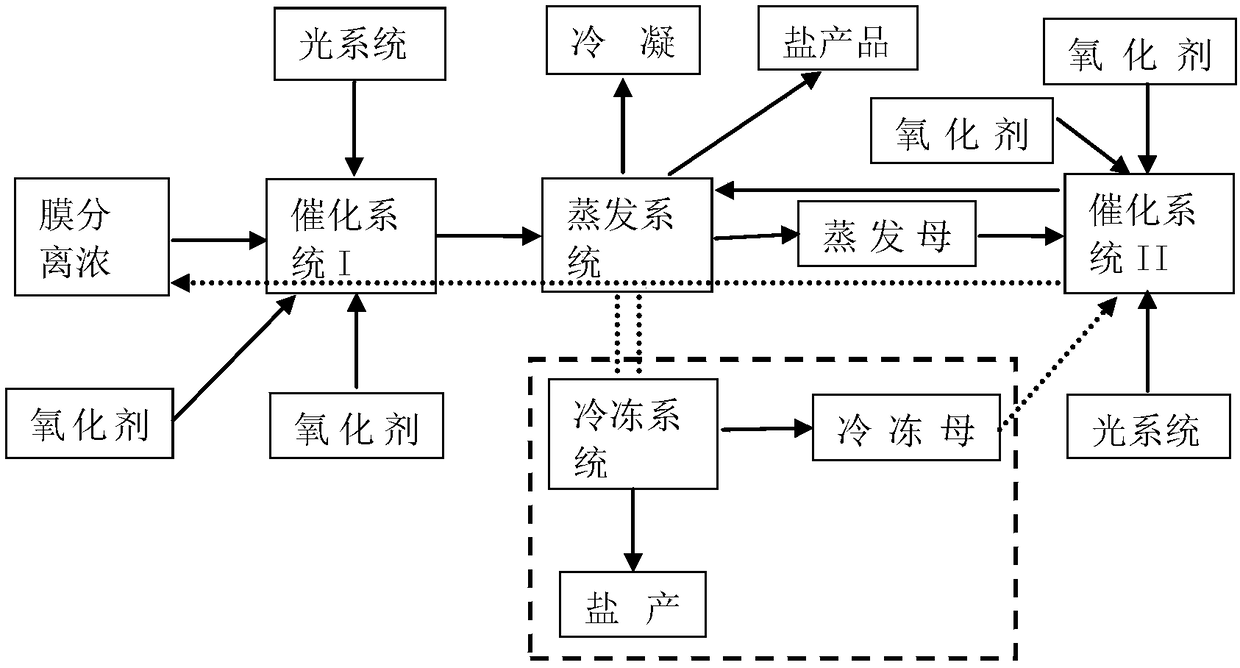

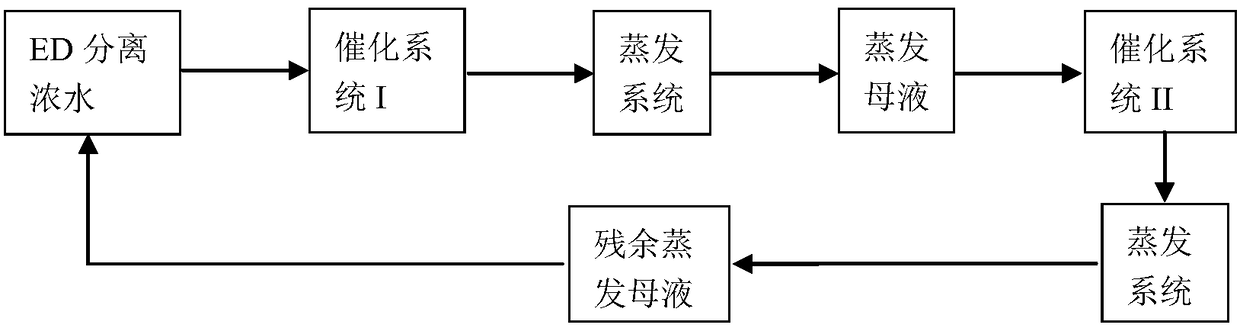

[0051] According to attached figure 2 The process structure shown is implemented:

[0052] S1: Concentrated electrodialysis water in a petrochemical industry contains 7.2-10.5% sodium chloride by weight, chroma 410, and COD 3250. Take 300ml and add it to a 1000ml beaker.

[0053] Use isopropyl titanate to hydrolyze under the condition of 0.2mol / L nitric acid aqueous solution, the hydrolysis temperature is 60°C, the time is 8h, apply it on the FTO conductive glass, and then bake it at 500°C for 2h to obtain nc-TiO 2 / FTO. The thickness of the catalyst is 1.2 μm, the cut area is 6cm×5cm, and the nc-TiO 2 / FTO was put into the beaker, and the distance between the catalyst and the liquid surface was adjusted to be 2cm.

[0054] S2: Infuse air from below the catalyst, balance for 30 minutes, and add 0.5% sodium hypochlorite;

[0055] S3: A 500W xenon lamp is used as the light source, and the light spot shines vertically on the liquid surface of the catalyst from the top of the...

Embodiment 2

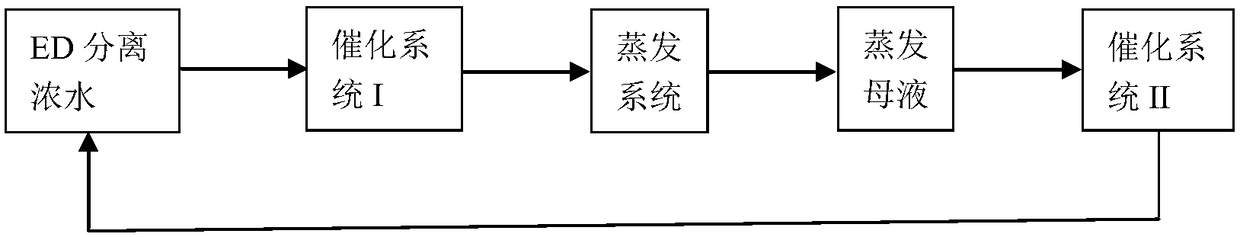

[0059] According to attached image 3 The process structure shown is implemented:

[0060] S1: Concentrated electrodialysis water in a petrochemical industry contains 7.2-10.5% sodium chloride by weight, chroma 410, and COD 3250. Take 300ml and add it to a 1000ml beaker.

[0061] Use isopropyl titanate to hydrolyze under the condition of 0.2mol / L nitric acid aqueous solution, the hydrolysis temperature is 60°C, the time is 8h, apply it on the FTO conductive glass, and then bake it at 500°C for 2h to prepare nc-TiO 2 / FTO. The thickness of the catalyst is 1.2 μm, the cut area is 6cm×5cm, and the nc-TiO 2 / FTO was put into the beaker, and the distance between the catalyst and the liquid surface was adjusted to be 2cm.

[0062] S2: Infuse air from below the catalyst, balance for 30 minutes, and add 0.5% hydrogen peroxide;

[0063] S3: A 500W xenon lamp is used as the light source, and the light spot shines vertically on the liquid surface of the catalyst from the top of the b...

Embodiment 3

[0067]According to attached Figure 4 The process structure shown is implemented:

[0068] Electrodialysis concentrated water in a petrochemical industry contains 7.2-10.5% sodium chloride by weight, 410 chroma, and 3250 COD. Take 300ml, add 300ml to a 500ml round bottom flask, heat with an electric furnace, distill under reduced pressure, and evaporate About 200ml of water was produced, a large amount of salt was precipitated, the heating was stopped, and the brine was separated by centrifugation to obtain 9.3g of sodium chloride. The salt was slightly yellow, and it was obvious that viscous organic matter remained in the salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com