Preparation method of benzotriazole ultraviolet light absorber

A technology of benzotriazoles and benzotriazoles is applied in the field of preparation of ultraviolet absorbers and can solve problems such as residues and product discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

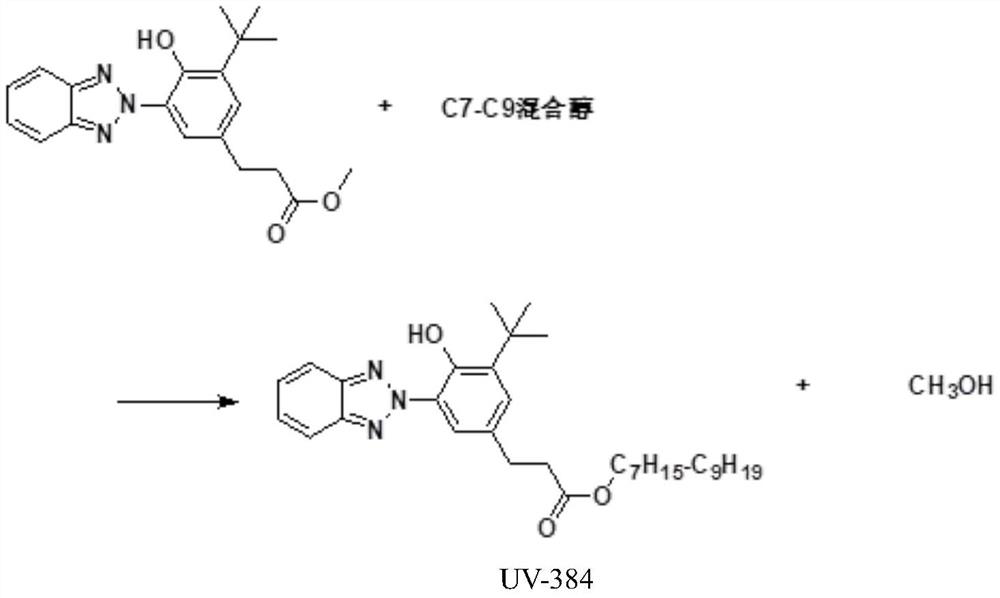

[0022] A preparation method of benzotriazole ultraviolet absorber: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propane Acid methyl ester, C 7 -C 9 The alkyl alcohol is used as a raw material, and a transesterification reaction occurs under the action of a catalyst to prepare 3-(2hydro-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4- Hydroxy-C 7 -C 9 Alkyl ester; the catalyst is lithium methylate and / or zinc isooctanoate.

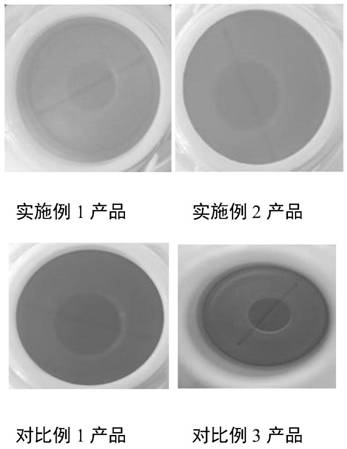

[0023] The study found that in the above reactions, the catalyst has a greater impact on the quality of the product. When p-toluenesulfonic acid is selected as the transesterification catalyst, due to the high temperature of the reaction system, p-toluenesulfonic acid is a strong acid substance, which is easy to cause corrosion of production equipment; also because of its strong acidity, the product is easy to change color under high temperature, resulting in The appearance of the product is dark in color and high in chroma. At the same time...

Embodiment 1

[0037] (1) Synthetic reaction: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid methyl ester 183.0g, C 7 -C 9 Add 100.0g of mixed alcohol into the reaction kettle, stir and heat up to 100-120°C, and remove light components under reduced pressure; then add 0.20g of catalyst lithium methoxide and 0.20g of zinc isooctanoate, heat up to 150-160°C, and gradually Start to decompress and react for 6 hours; the content of 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid methyl ester in the system is less than 0.5% After that, continue to increase the vacuum degree, and the excess C 7 -C 9 The mixed alcohol is removed; then the temperature is lowered to 100-120°C.

[0038] (2) Decolorization and post-treatment: Add 8.0 g of activated clay to the dealcoholization reaction solution obtained in step (1), stir at 110-115° C. for 1 hour, carry out catalyst adsorption and decolorization, and the chromaticity of sampling detection is 3.2 ...

Embodiment 2

[0040] (1) Synthetic reaction: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid methyl ester 183.0g, C 7 -C 9 Add 100.0g of mixed alcohol into the reaction kettle, stir and heat up to 100-120°C, remove light components under reduced pressure; then add 0.40g of catalyst lithium methoxide and 0.20g of zinc isooctanoate, heat up to 150-160°C, and gradually Start to decompress and react for 4.5 hours; the content of 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid methyl ester in the system is less than 0.5 % After that, continue to increase the vacuum degree, the excess C 7 -C 9 The mixed alcohol is removed; then the temperature is lowered to 100-120°C.

[0041] (2) Decolorization and post-treatment: Add 10.0 g of activated clay to the dealcoholization reaction solution obtained in step (1), stir at 110-115° C. for 1 hour, carry out catalyst adsorption and decolorization, and the chromaticity of sampling detection is 3.4 Gardn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com