Preparation method for noble wine flavored high-alcohol sweet bear

A technology of alcohol content and flavor, applied in beer fermentation methods, beer brewing, malt preparation, etc., can solve the problems of impossible development of beer with rich fruity aroma, etc., and achieve high saccharification power, high amino nitrogen content, and full dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

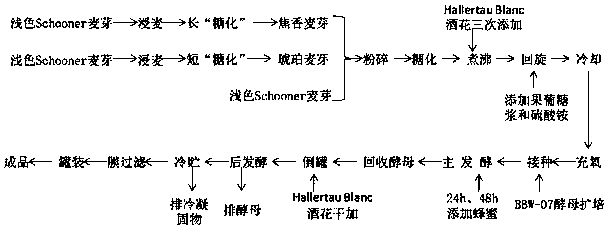

[0043] Production of high-alcohol sweet beer with noble rot wine flavor in 30L fermentation line, the process route is as attached in the manual figure 2 Shown:

[0044] Schooner light-colored malt for saccharification: saccharifying power 340°WK, α-amino nitrogen 210mg / 100mL, pool value 47.6%, chroma 4.1EBC, pH 5.71.

[0045] Preparation and indicators of Schooner caramel malt for saccharification: Soak 10 kg of Schooner light-colored malt in warm water at 35°C for 10 hours, so that the malt particles can fully absorb water to 45%, and then drain for 0.6 hours. Put the drained malt into the Zhejiang Guansheng 2550-100 multifunctional drum-type roaster, heat up to 69°C, and keep warm for 1.49h. Slowly raise the temperature to 90°C for 45 minutes to drain the moisture, and control the moisture at 28% after the moisture is drained. Then rapidly raise the temperature to 110°C for baking and coloring, and the baking time is 100 minutes. After roasting, spread the malt thinly, l...

Embodiment 2

[0066] The production of high-alcohol sweet beer with noble rot wine flavor on the 100L Zunhuang Fermentation Line, the process route is as attached in the manual figure 2 Shown:

[0067] Schooner light-colored malt for saccharification: saccharification power 345°WK, α-amino nitrogen 220mg / 100mL, pool value 46.5%, chroma 4.08EBC, pH 5.72.

[0068] Preparation and indicators of Schooner caramel malt for saccharification: Soak 10 kg of Schooner light-colored malt in warm water at 35°C for 10 hours, so that the malt particles can fully absorb water to 45%, and then drain the water for 0.6 hours. Put the drained malt into the Zhejiang Guansheng 2550-100 multifunctional drum-type roaster, heat up to 69°C, and keep warm for 1.49h. Slowly raise the temperature to 90°C and drain the moisture for 45 minutes, and control the moisture at 28% after the moisture is drained. Then rapidly raise the temperature to 110°C for baking and coloring, and the baking time is 100 minutes. After r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com