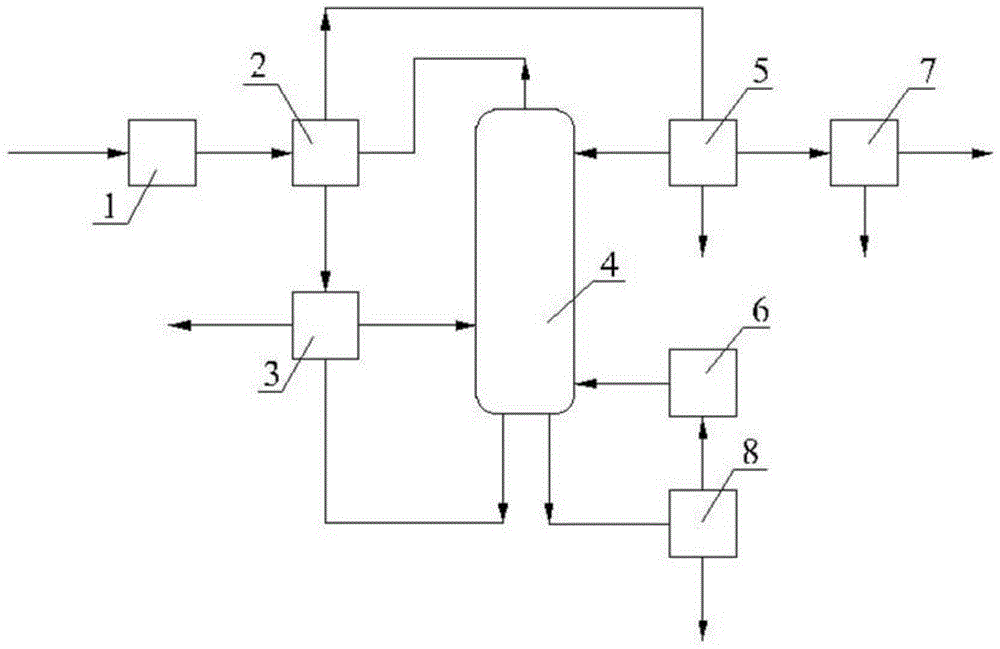

Continuous treatment process and equipment for neopentyl glycol condensation water washing mother liquor

A technology of neopentyl glycol and mother liquor, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of long operation period, large loss of neopentyl glycol, low production efficiency, etc., to reduce production costs, Effects of improving appearance characteristics and increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Implementation example 1: The feed rate of neopentyl glycol condensation water washing mother liquor is 4000 kg / h, the temperature rises from 20°C to 70°C after passing through the primary preheater, and the temperature rises to 90°C after passing through the secondary preheater , The temperature of the bottom material of the rectification tower dropped from 109°C to 75°C, and the steam consumption was 450 kg / hour. The treatment time of 20 tons of neopentyl glycol solution is about 5 hours, the volume of dichloromethane produced at the top of the tower is 800 liters, and the volume of petroleum ether is 500 liters. After the water produced at the top of the tower passes through the water separator, the neopentyl glycol content is 8ppm and the COD is 236 mg / liter, and the mass fraction of neopentyl glycol produced at the bottom of the tower is 70%, wherein dichloromethane and petroleum ether Not detected.

Embodiment 2

[0032] Implementation example 2: The feed rate of neopentyl glycol condensation water washing mother liquor is 4000 kg / h, the temperature rises from 20°C to 75°C after passing through the first-stage preheater, and the temperature rises to 95°C after passing through the second-stage preheater , The temperature of the bottom material of the rectification tower dropped from 108°C to 70°C, and the steam consumption was 400 kg / hour. The treatment time of 20 tons of neopentyl glycol solution is about 5 hours, the volume of dichloromethane extracted from the tower top is 830 liters, and the volume of petroleum ether is 550 liters. After the water produced at the top of the tower passes through the water separator, the content of neopentyl glycol is 9ppm and the COD is 156 mg / liter, and the mass fraction of neopentyl glycol produced at the bottom of the tower is 68%, of which dichloromethane and petroleum ether The concentration is 1ppm.

Embodiment 3

[0033] Implementation example 3: The feed rate of neopentyl glycol condensation water washing mother liquor is 5000 kg / hour, the temperature rises from 20°C to 65°C after passing through the primary preheater, and the temperature rises to 92°C after passing through the secondary preheater , The temperature of the bottom material of the rectification tower dropped from 108°C to 72°C, and the steam consumption was 550 kg / hour. The treatment time of 20 tons of neopentyl glycol solution is about 4 hours, the volume of dichloromethane extracted from the tower top is 850 liters, and the volume of petroleum ether is 520 liters. After the water produced at the top of the tower passes through the water separator, the neopentyl glycol content is 5ppm and the COD is 221 mg / liter, and the concentrated mass fraction of neopentyl glycol produced at the bottom of the tower is 67%, of which dichloromethane and petroleum The ether concentration was 1 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com