Coagulant for treating polysulfonate slurry sewage

A coagulant and mud technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of low chroma treatment efficiency, achieve the effect of improving chroma removal rate and accelerating flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

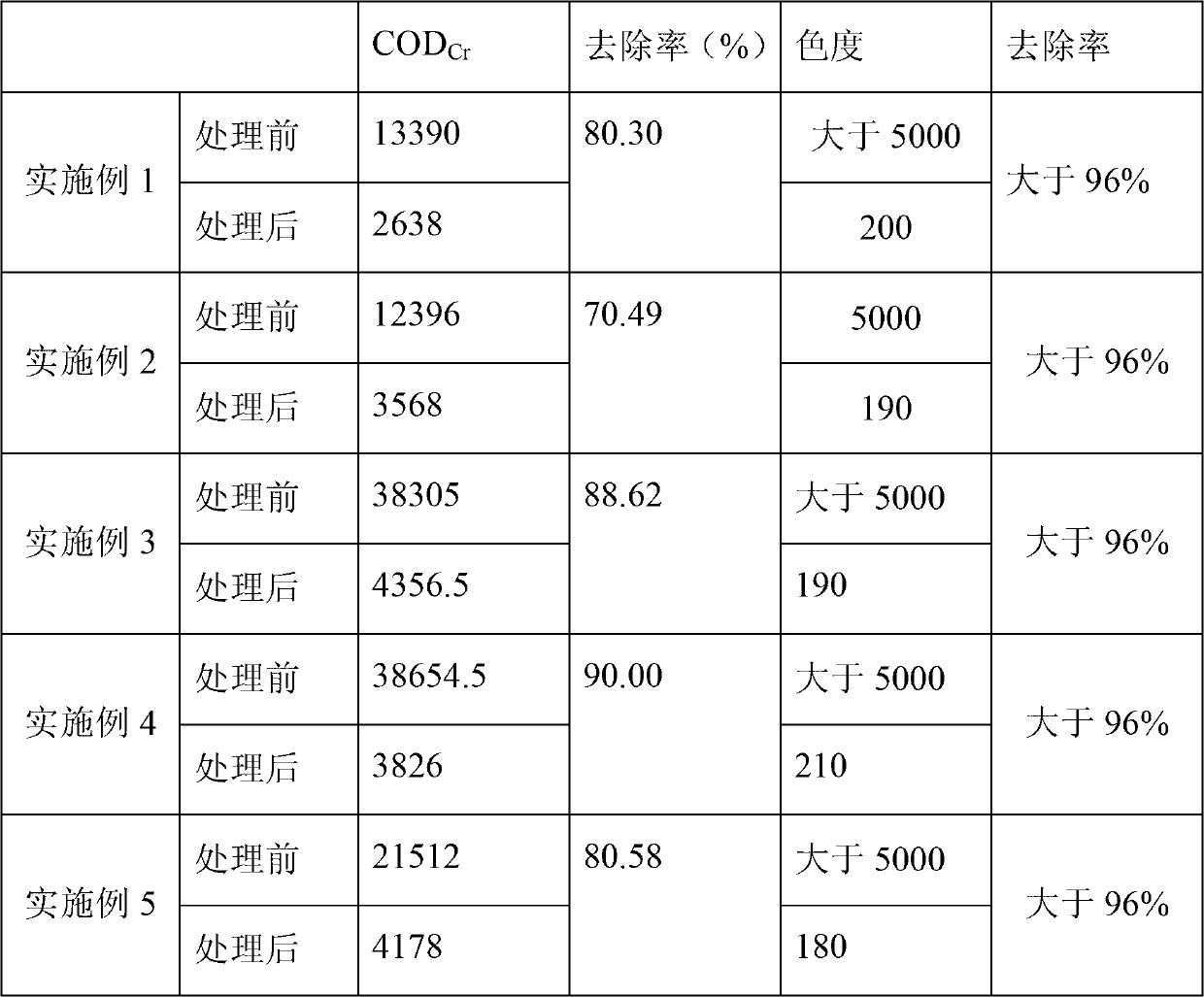

Embodiment 1

[0017] Select I1L of polysulfide mud sewage sample from drilling in a certain area of Sichuan to analyze the COD in the sewage Cr And measure chromaticity with dilution multiple method, add the coagulant that the processing polysulfide mud sewage provided by the present invention is processed in order then, wherein calcium hydroxide add-on is 4g, and ferrous sulfate add-on is 11.5g, analysis and treatment after sewage.

Embodiment 2

[0019] Select II1L of polysulfide mud sewage sample from drilling in a certain area of Sichuan to analyze the COD in the sewage Cr And measure chromaticity with dilution multiple method, then add the coagulant that the present invention provides to process polysulfide mud sewage in order and process it, wherein calcium hydroxide add-on is 5g, and ferrous sulfate add-on is 11.5g, analyzes Treated sewage.

Embodiment 3

[0021] Select III1L of polysulfide mud sewage sample from a certain area in Sichuan to analyze COD in sewage Cr And measure chromaticity with dilution multiple method, then add the coagulant that the present invention provides in order to process polysulfide mud sewage and process it, wherein calcium hydroxide add-on is 4g, ferrous sulfate add-on is 8.7g, then Then, 50 mg of polyacrylamide was added to the sewage treated by the above treatment steps, and the treated sewage was analyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com