Composite water quality agglutination purifying agent and preparation method thereof

A composite, purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The problem of slow hydrolysis speed of flocculant can achieve the effect of improving long-term treatment effect, increasing stability and fast sedimentation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

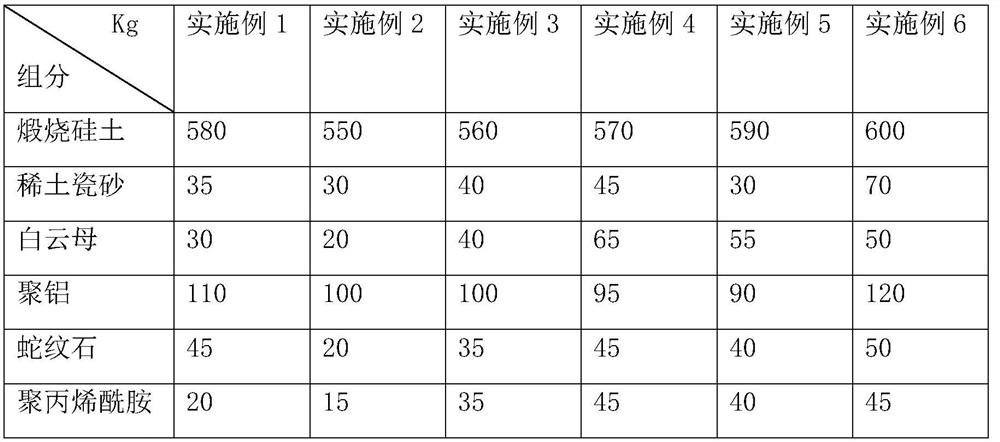

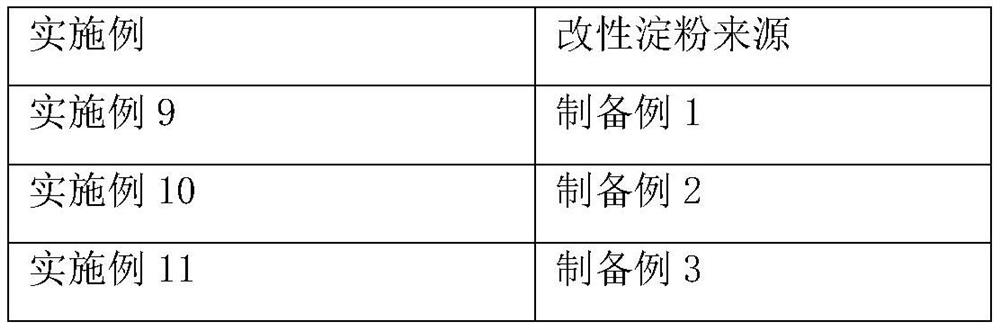

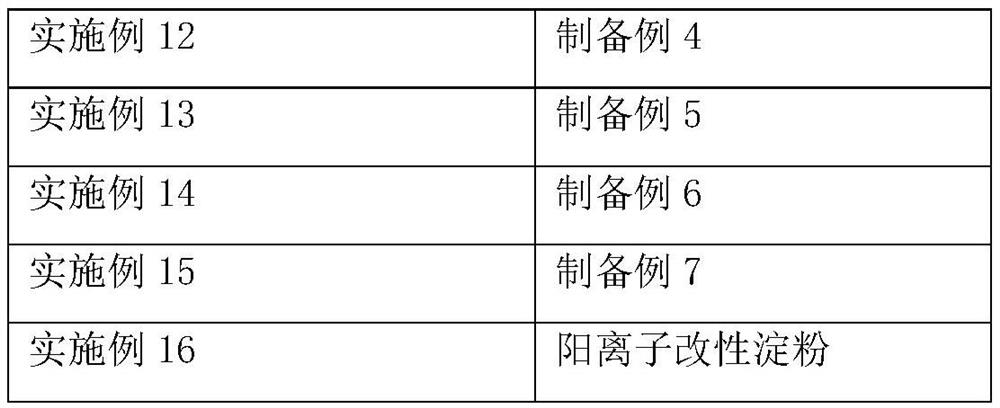

Examples

preparation example 1

[0061] Preparation Example 1: (1) Mix 8Kg starch with 1.5Kg oxidant, after mixing evenly, under the action of 400W microwave, heat at 60°C for 7min, adjust the pH value to 8, add 1Kg carboxymethyl cellulose and 0.1Kg Sodium tetraborate, defoaming after stirring evenly, the oxidizing agent is the potassium permanganate that weight percent concentration is 1%;

[0062] (2) Mix 1.1Kg of sodium bentonite and 2Kg of distilled water to make a suspension, heat to 80°C, add 0.5Kg of glycerin, keep stirring for 30 minutes, then add 2.5Kg of PVA, keep stirring for 1 hour, centrifuge, dry and grind;

[0063] (3) Mix the product of step (1) with the product of step (2), add 0.5Kg initiator and 5Kg distilled water, heat up to 45°C, keep stirring for 4h, and dry at 50°C. The initiator is ammonium persulfate.

preparation example 2

[0064] Preparation Example 2: (1) Mix 10Kg starch with 2Kg oxidizing agent, after mixing evenly, under the action of 400W microwave, heat at 75°C for 3min, adjust the pH value to 10, add 1.5Kg carboxymethyl cellulose and 0.3Kg Sodium tetraborate, defoaming after stirring evenly, oxidizing agent is the hydrogen peroxide that weight percent concentration is 30%;

[0065] (2) Mix 1.5Kg of sodium bentonite and 3Kg of distilled water to make a suspension, heat to 90°C, add 1Kg of glycerol, keep stirring for 40min, then add 3Kg of PVA, keep stirring for 2h, centrifuge, dry and grind;

[0066] (3) Mix the product of step (1) with the product of step (2), add 1Kg initiator and 7Kg distilled water, heat up to 60°C, keep stirring for 3h, and dry at 60°C. The initiator is ammonium persulfate.

preparation example 3

[0067] Preparation Example 3: The difference from Preparation Example 1 is that the product of step (2) is not added in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com