A kind of composite water agglutination and purification agent and preparation method thereof

A composite, purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The problem of slow hydrolysis speed of flocculant can increase the stability, improve the long-term treatment effect, and achieve the effect of fast sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

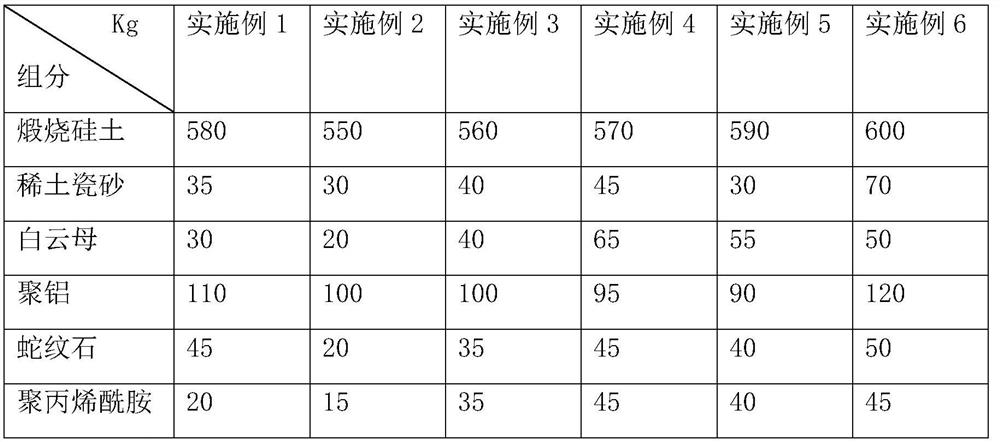

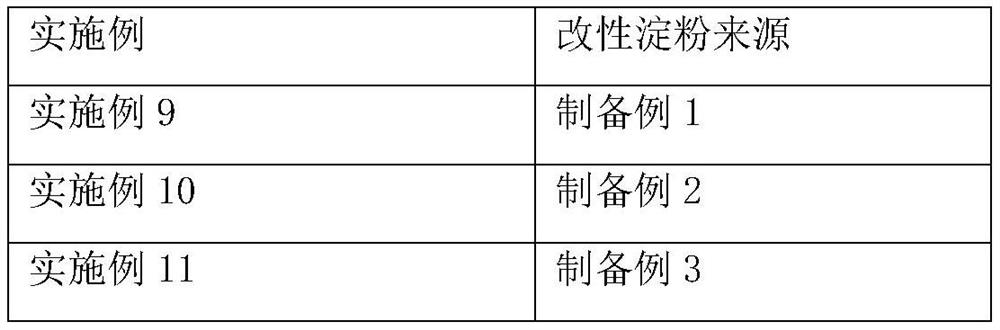

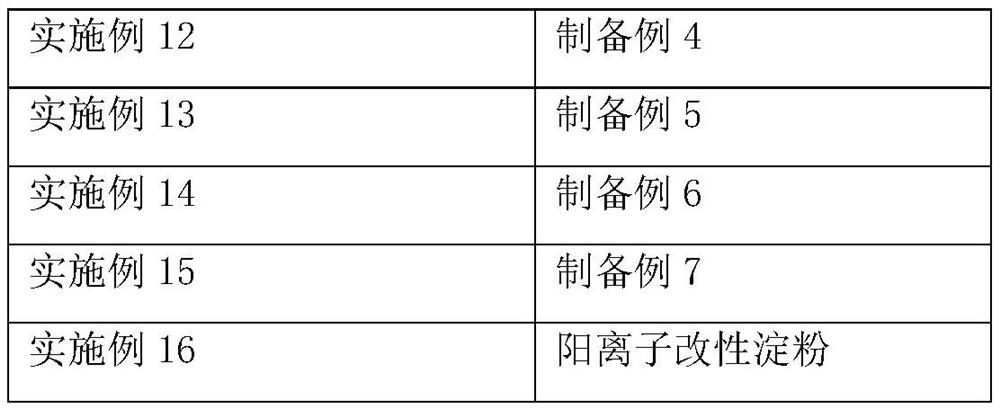

Examples

preparation example 1

[0061] Preparation Example 1: (1) Mix 8Kg starch with 1.5Kg oxidant, and after mixing evenly, under the action of 400W microwave, heat at 60°C for 7min, adjust the pH value to 8, add 1Kg carboxymethyl cellulose and 0.1Kg Sodium tetraborate, after stirring, defoaming, the oxidant is potassium permanganate with a concentration of 1% by weight;

[0062] (2) Mix 1.1Kg sodium bentonite with 2Kg distilled water to make a suspension, heat to 80°C, add 0.5Kg glycerol, keep stirring for 30min, add 2.5Kg PVA, keep stirring for 1h, centrifuge, dry and grind;

[0063] (3) Mix the result of step (1) with the result of step (2), add 0.5Kg initiator and 5Kg distilled water, heat up to 45°C, keep stirring for 4h, and dry at 50°C, and the initiator is ammonium persulfate.

preparation example 2

[0064] Preparation Example 2: (1) Mix 10Kg of starch with 2Kg of oxidizing agent, after mixing evenly, under the action of 400W microwave, heat at 75°C for 3min, adjust the pH value to 10, add 1.5Kg of carboxymethyl cellulose and 0.3Kg Sodium tetraborate, after stirring evenly, defoaming, the oxidant is hydrogen peroxide with a concentration of 30% by weight;

[0065] (2) Mix 1.5Kg of sodium bentonite with 3Kg of distilled water to make a suspension, add 1Kg of glycerol after heating to 90°C, keep stirring for 40min, then add 3Kg PVA, keep stirring for 2h, centrifuge, dry and grind;

[0066] (3) Mix the resultant of step (1) and the resultant of step (2), add 1Kg of initiator and 7Kg of distilled water, heat up to 60°C, keep stirring for 3h, and dry at 60°C, and the initiator is ammonium persulfate.

preparation example 3

[0067] Preparation Example 3: The difference from Preparation Example 1 is that the product of step (2) is not added in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com