Integrated combination device for physicochemical treatment of black liquid

A combination of equipment and black liquor technology, applied in papermaking black liquor physical and chemical treatment equipment, refers to the field of papermaking black liquor treatment equipment, which can solve the problem of low extraction rate of high-concentration black liquor, high silicon content, increasing the difficulty of middle-stage water compliance and governance Investment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

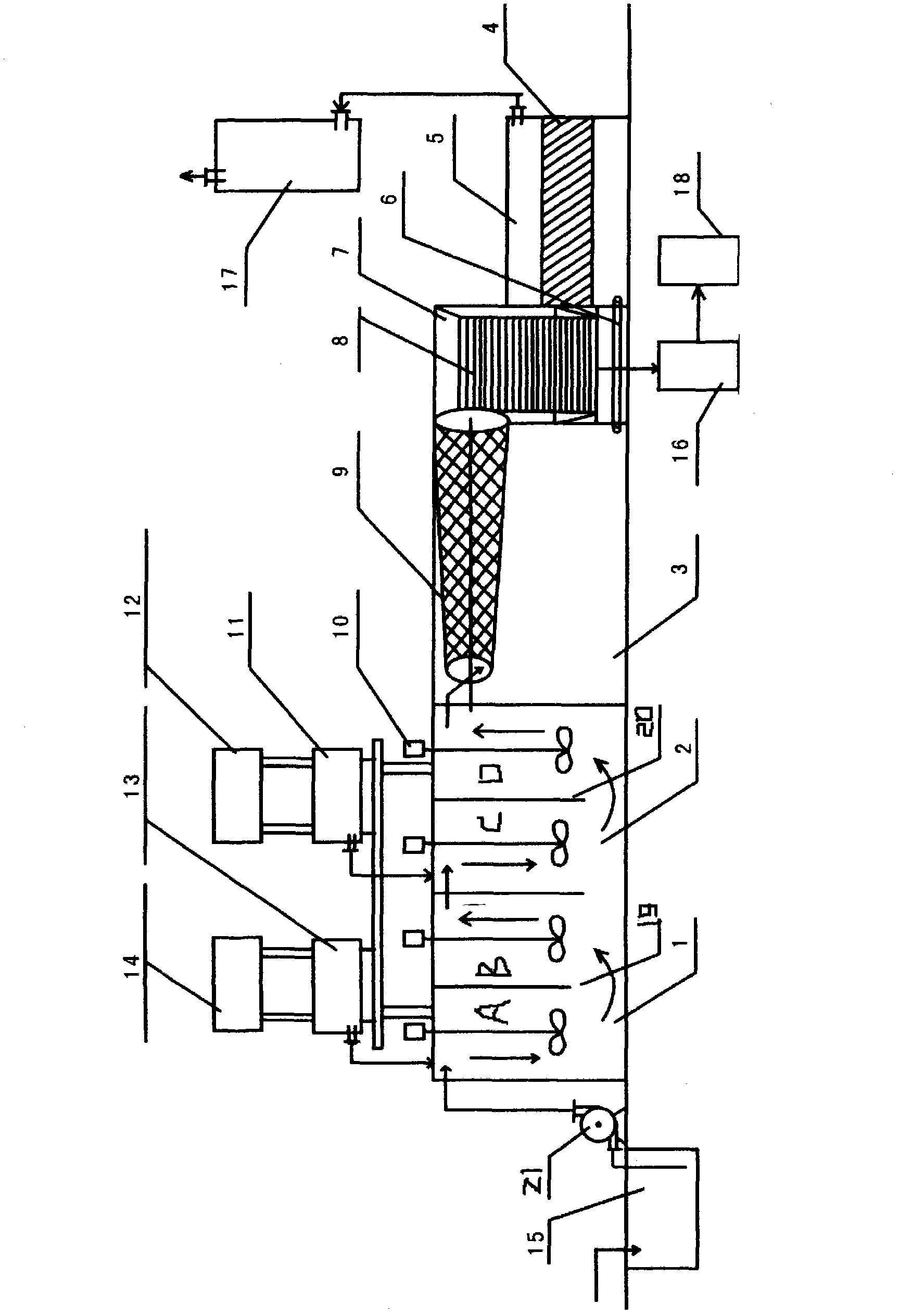

[0017] The black liquor physical and chemical treatment integrated combined equipment of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the black liquor produced in the papermaking and pulping section according to the flow chart of the accompanying drawing enters the black liquor acidification tank 15 for acidification treatment, so that the black liquor with different concentrations of high and low concentrations can be mixed homogeneously, so that the residual alkali and chemical oxygen consumption can be initially degraded and reduced. running costs. After the acidification treatment, the black liquor lifting pump 21 is lifted to the oxidation decomposition chamber 1. At the same time, the drug storage tank 14 and the metering tank 13 on the upper part of the oxidation decomposition chamber 1 are set up to quantitatively add the oxidation decomposition liquid medicine to the oxidation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com