Preparing method for dyeing waste water treating agent

A printing and dyeing sewage and treatment agent technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory effect and low efficiency of printing and dyeing wastewater treatment, and improve the color High removal rate, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

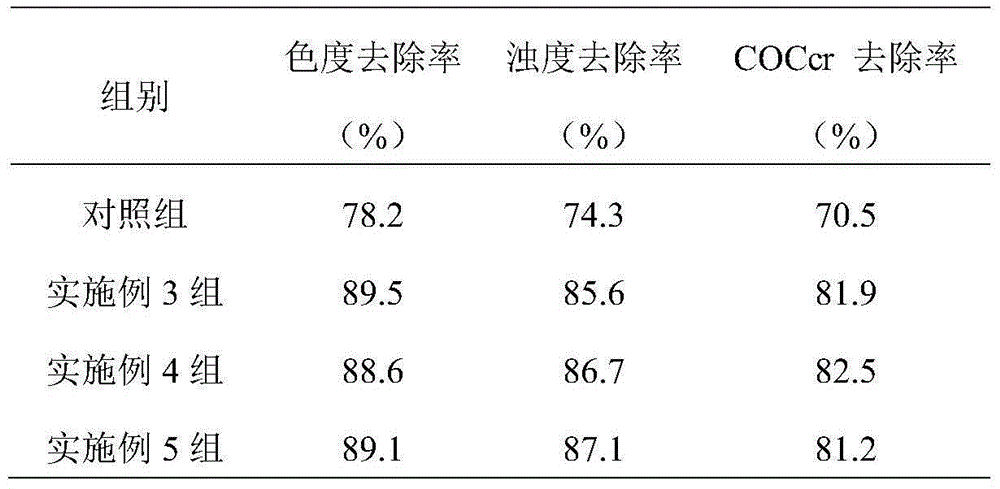

Examples

Embodiment 1

[0029] Party:

[0030] 10 parts of sodium polyacrylate, 5 parts of starch, 30 parts of bentonite, 5 parts of iron sulfate, 5 parts of alum,

[0031] 0.5 parts of aluminum sulfate, 1 part of activated carbon, 1 part of basic alumina, 0.5 parts of ferrous sulfate,

[0032] 0.2 parts of nickel nitrate, 10 parts of chitosan, and 0.02 parts of polysorbate.

[0033] The viscosity-average molecular weight of the sodium polyacrylate is 4000, and the molecular weight of the chitosan is 8000.

[0034] Preparation:

[0035] (1) get bentonite, ferric sulfate, alum, aluminum sulfate, gac, basic alumina, ferrous sulfate and nickel nitrate, mix, be ground into fine powder;

[0036] (2) Take chitosan, add a certain amount of pure water, heat and dissolve at 50°C, then add sodium polyacrylate and starch, stir, keep warm, and obtain an intermediate material;

[0037] (3) Mix the above-mentioned fine powder and the intermediate material, add polysorbate, stir at 40°C and 3000r / min for 10h, a...

Embodiment 2

[0039] Party:

[0040] 10 parts of sodium polyacrylate, 25 parts of starch, 50 parts of bentonite, 15 parts of iron sulfate, 15 parts of alum,

[0041] 1.5 parts of aluminum sulfate, 9 parts of activated carbon, 7 parts of basic alumina, 1.5 parts of ferrous sulfate,

[0042] 0.8 parts of nickel nitrate, 20 parts of chitosan, and 0.08 parts of polysorbate.

[0043] The viscosity-average molecular weight of the sodium polyacrylate is 6000, and the molecular weight of the chitosan is 12000.

[0044] Preparation:

[0045] (1) get bentonite, ferric sulfate, alum, aluminum sulfate, gac, basic alumina, ferrous sulfate and nickel nitrate, mix, be ground into fine powder;

[0046] (2) Take chitosan, add a certain amount of pure water, heat and dissolve at 70°C, then add sodium polyacrylate and starch, stir, and keep warm to obtain the intermediate material;

[0047] (3) Mix the above-mentioned fine powder and the intermediate material, add polysorbate, stir at 60°C and 5000r / min f...

Embodiment 3

[0049] Party:

[0050] 10 parts of sodium polyacrylate, 15 parts of starch, 40 parts of bentonite, 10 parts of iron sulfate, 10 parts of alum,

[0051] 1 part of aluminum sulfate, 5 parts of activated carbon, 4 parts of basic alumina, 1 part of ferrous sulfate,

[0052] 0.5 parts of nickel nitrate, 15 parts of chitosan, and 0.05 parts of polysorbate.

[0053] The viscosity-average molecular weight of the sodium polyacrylate is 5000, and the molecular weight of the chitosan is 10000.

[0054] Preparation:

[0055] (1) get bentonite, ferric sulfate, alum, aluminum sulfate, gac, basic alumina, ferrous sulfate and nickel nitrate, mix, be ground into fine powder;

[0056] (2) Take chitosan, add a certain amount of pure water, heat and dissolve at 60°C, then add sodium polyacrylate and starch, stir, keep warm, and obtain an intermediate material;

[0057] (3) Mix the above-mentioned fine powder and the intermediate material, add polysorbate, stir at 50°C and 4000r / min for 15h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com