A kind of enzyme precatalysis-magnetoacoustic catalytic oxidation advanced water treatment method

A catalytic oxidation and pre-catalysis technology, which is applied in the field of water pollution prevention and control research, can solve the problems that small molecular organic matter is difficult to completely decompose, it is difficult to meet the emission standards stably, and the treatment cost is high, so as to reduce the treatment cost and oxidation reaction rate. and high oxidation capacity, the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

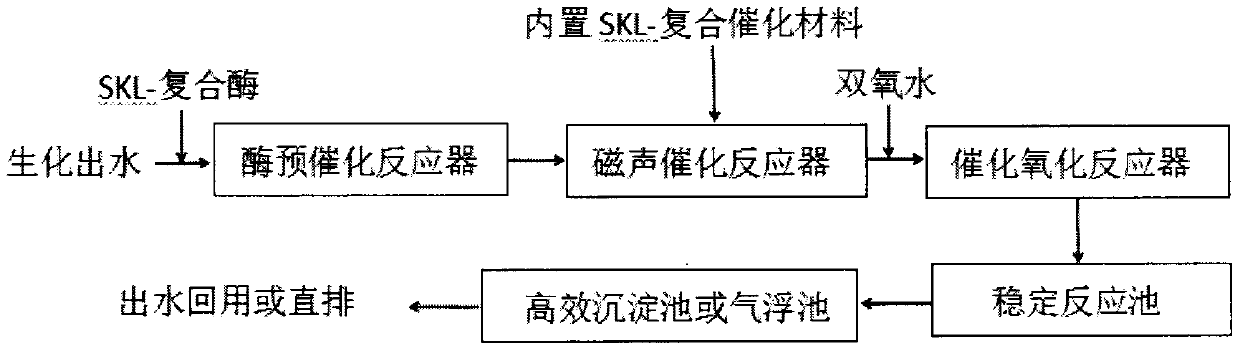

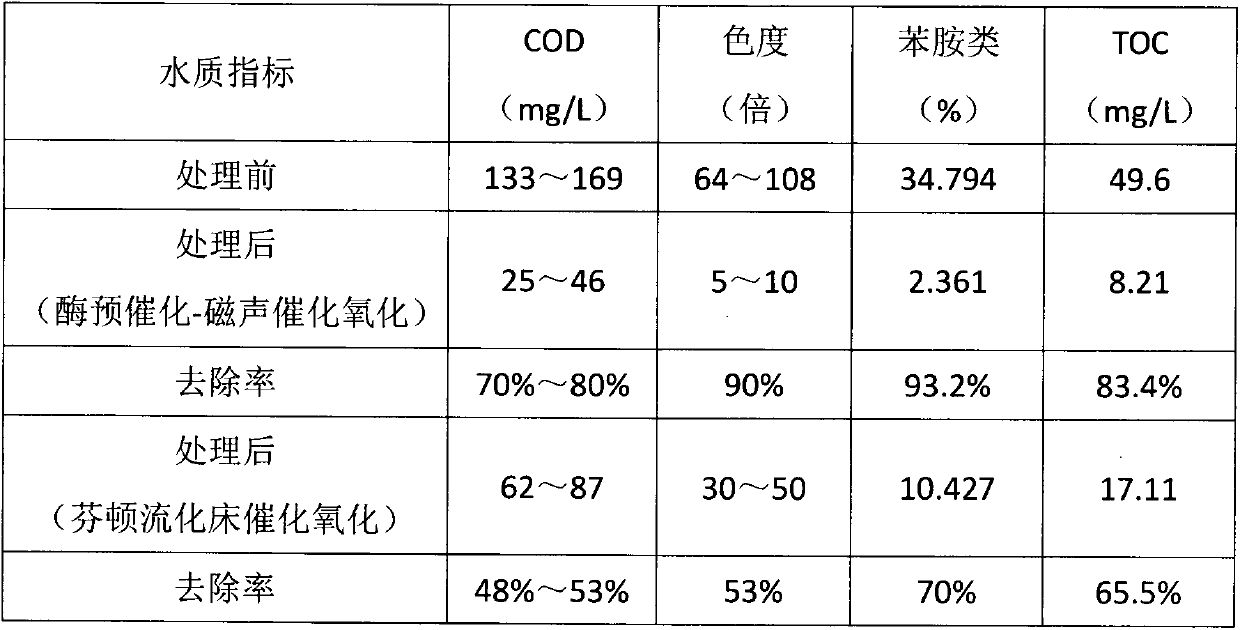

[0044] Embodiment 1: printing and dyeing wastewater

[0045] A comprehensive sewage treatment plant in Zhejiang, in which printing and dyeing wastewater accounted for 75%, chemical wastewater accounted for 15%, and domestic wastewater accounted for 10%, with a daily treatment capacity of 320,000 tons. The effluent from the secondary settling tank after biochemical treatment is COD130~160mg / L, the chroma is relatively heavy, and the conductivity is greater than 4000us / cm. There are 14 kinds of organic pollutants with a larger molecular weight exceeding 1%, accounting for 88.83% in total, and the content of aniline organic pollutants is 34.79%. The present inventor has carried out the pilot test of enzyme precatalysis-magnetoacoustic catalytic oxidation advanced water treatment method to this waste water, has obtained good treatment effect, the index degradation effect such as COD, TOC, chromaticity, anilines is obvious, and effluent water quality index meets The GB18918-2002 G...

Embodiment 2

[0067] Embodiment 2: pharmaceutical wastewater

[0068] A sewage treatment plant in Shijiazhuang has a daily water treatment capacity of 100,000 tons. The source of advanced treatment wastewater is the upstream pharmaceutical enterprise wastewater and urban domestic sewage. Finally, the effluent is required to meet the first-level A standard of the urban sewage treatment plant pollutant discharge standard (GB18918-2002). The original advanced treatment of the plant used the ozone / activated carbon filter process, which failed to reach the standard after a period of operation, and with the adsorption and saturation of activated carbon, the effluent effect became worse. The influent water quality of the plant is complex and fluctuates greatly, the inert COD increases, and the biodegradability and oxidizability are greatly reduced. COD rose to 150mg / L. The ammonia nitrogen is between 5.8~7.4mg / L, and the total phosphorus is between 0.93~1.73mg / L. Aiming at the national first-cl...

Embodiment 3

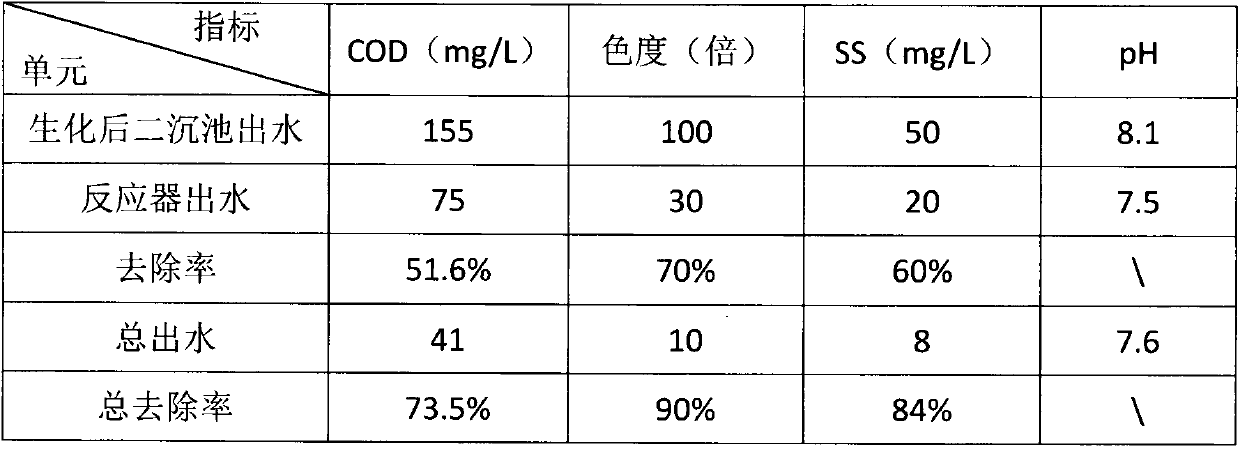

[0085] Embodiment 3: chemical fiber waste water

[0086] A sewage treatment station in Xinjiang mainly treats fiber wastewater and pulp wastewater from a fiber company in Xinjiang, with a daily processing capacity of 80,000 tons. The water volume of advanced water treatment is 40,000 tons per day, and the target COD ≤ 30mg / L is treated in the reclaimed water reuse system and then reused for production, meeting the reclaimed water reuse requirements of the environmental protection department of Xinjiang Autonomous Region. After physical and chemical + biochemical (aerated activated sludge method) treatment, the COD of the biochemical effluent is now 70-120mg / L. Advanced treatment implements the enzyme-catalyzed-magnetoacoustic catalytic oxidation advanced water treatment process of the present invention.

[0087] Technical Parameters:

[0088] The daily deep water treatment scale is 40,000 tons. Enzyme precatalysis time 8min, enzyme precatalysis reactor volume 115m 3 ;The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com