Advanced treatment process for degumming wastewater of ramie

A technology of advanced treatment and wastewater, applied in water/sewage treatment, natural water treatment, biological water/sewage treatment, etc., it can solve the problem of unsatisfactory effect of ramie degumming wastewater, reduce input, high COD removal rate, The effect of high chroma removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

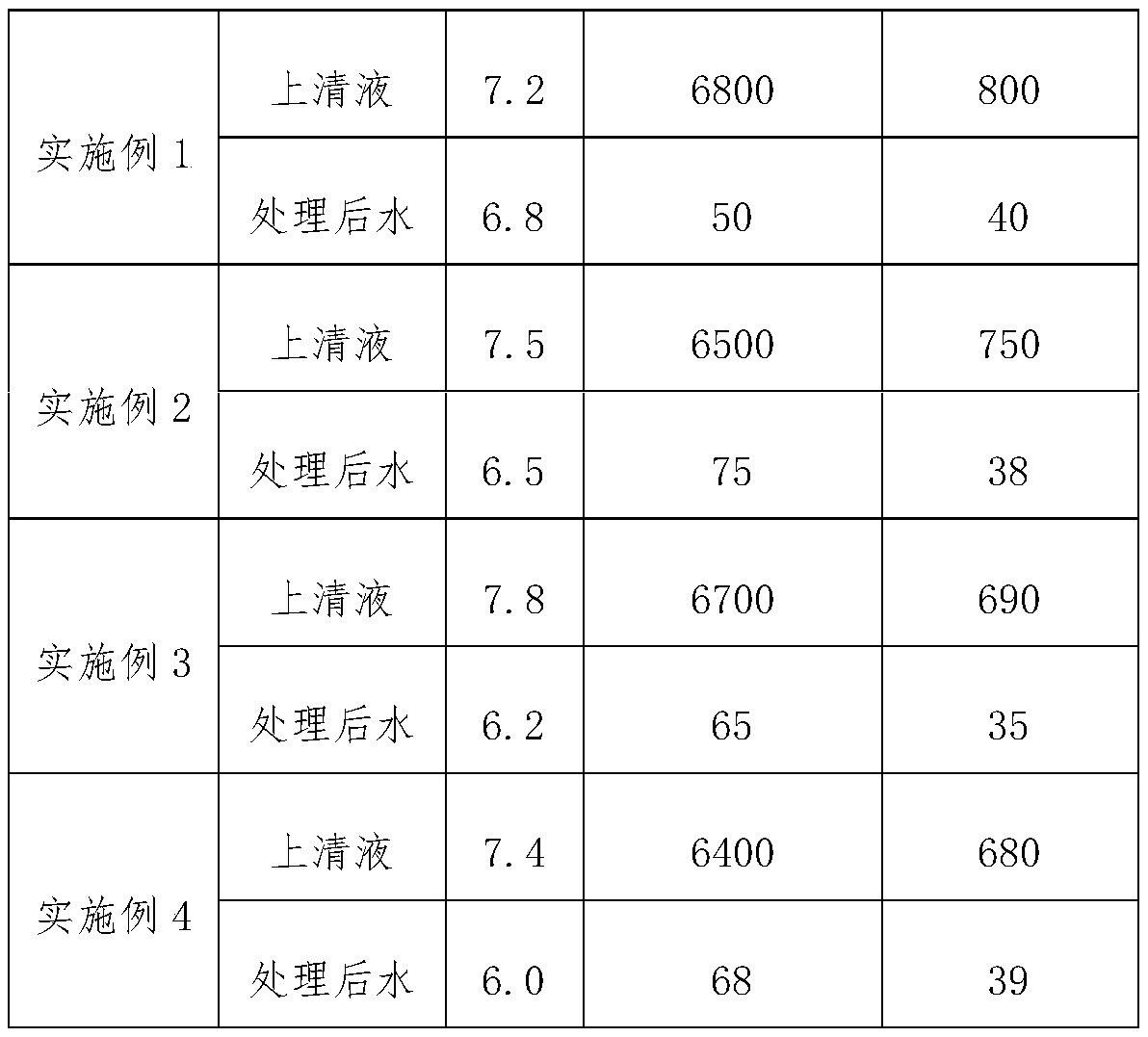

Embodiment 1

[0020] The present embodiment provides a kind of ramie degumming wastewater advanced treatment process, comprising:

[0021] (1) Using sulfuric acid to adjust the pH of the scouring wastewater to 3; then adding 1.5% bio-enzyme by weight of the scouring wastewater and reacting at 43°C for 3 hours. Biological enzymes include pectinase, hemicellulase and xylanase with a mass ratio of 1:2:1.5, and are filtered to obtain the first treatment liquid;

[0022] (2) Add ferrous sulfate and hydrogen peroxide to the first treatment liquid for treatment. The amount of ferrous salt added is 1‰ of the weight of the first treatment solution; the amount of hydrogen peroxide added is 2‰ of the weight of the first treatment solution, treated for 60 minutes, and filtered to obtain the second treatment solution;

[0023] (3) Add quicklime to the second treatment solution. The addition of unslaked lime is 4‰ of the first treatment liquid, leave standstill after stirring, and take the supernatant;...

Embodiment 2

[0026] The present embodiment provides a kind of ramie degumming wastewater advanced treatment process, comprising:

[0027] (1) Using sulfuric acid to adjust the pH of the scouring wastewater to 5; then adding 2% bio-enzyme by weight of the scouring wastewater and reacting at 52° C. for 3 hours. Biological enzymes include pectinase, hemicellulase and xylanase with a mass ratio of 2:3:2, and are filtered to obtain the first treatment solution;

[0028] (2) Add ferrous sulfate and hydrogen peroxide to the first treatment liquid for treatment. The addition of ferrous salt is 8‰ of the weight of the first treatment solution; the addition of hydrogen peroxide is 4‰ of the weight of the first treatment solution, and the treatment is 80min, and the second treatment solution is obtained by filtration;

[0029] (3) Add quicklime to the second treatment liquid. The addition of unslaked lime is 12‰ of the first treatment liquid, leave standstill after stirring, and take the supernatan...

Embodiment 3

[0032] The present embodiment provides a kind of ramie degumming wastewater advanced treatment process, comprising:

[0033] (1) Using sulfuric acid to adjust the pH of the scouring wastewater to 4; then adding 1.8% bio-enzyme by weight of the scouring wastewater and reacting at 50°C for 2.5 hours. Biological enzymes include pectinase, hemicellulase and xylanase with a mass ratio of 1.5:2.5:1.8, and are filtered to obtain the first treatment solution;

[0034] (2) Add ferrous sulfate and hydrogen peroxide to the first treatment liquid for treatment. The addition of ferrous salt is 5‰ of the weight of the first treatment solution; the addition of hydrogen peroxide is 3‰ of the weight of the first treatment solution, and the treatment is 70min, and the second treatment solution is obtained by filtration;

[0035] (3) Add quicklime to the second treatment liquid. The addition of unslaked lime is 8‰ of the first treatment liquid, leave standstill after stirring, and take the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com