Process and device for efficiently treating wheat straw pulp intermediate wastewater by alkaline method

A technology for wheat straw pulp and wastewater, which is applied in the process of wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. The effect of sludge treatment cost, less sludge output and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

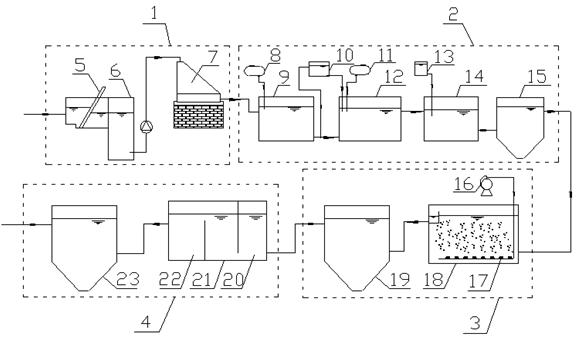

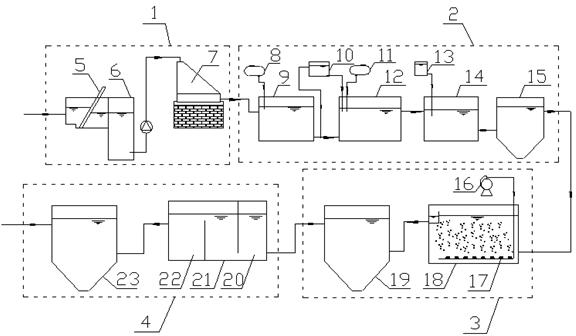

[0041] Example 1 :A device for realizing the middle-stage wastewater treatment process of wheat straw pulp by figure 1 As shown, it mainly includes a pretreatment device 1, a Fenton preoxidation device 2, an aerobic treatment device 3, and a coagulation precipitation treatment device 4. The pretreatment device 1, the Fenton preoxidation device 2, the aerobic treatment device 3 and the coagulation precipitation treatment device 4 are sequentially connected by pipelines.

[0042] The pretreatment device 1 mainly includes a fine grid 5, a collecting basin 6, and an inclined net 7. The fine grid 5, the collecting basin 6, and the inclined net 7 are connected by pipelines in sequence.

[0043] The Fenton pre-oxidation device 2 mainly includes a concentrated sulfuric acid storage tank 8, a pH adjustment tank 9, and FeSO 4 Dosing tank 10, H 2 O 2 Storage tank 11, Fenton oxidation tank 12, lye dosing device 13, neutralization tank 14 and primary sedimentation tank 15. The pH adjustment t...

Embodiment 2

[0052] Example 2: Except that the flocculant added in the coagulation sedimentation treatment step is polyferric sulfate (PFS), the dosage is 90mg / L. The coagulant aid is polyacrylamide (PAM), and the dosage is the same as in Example 1, except that the dosage is 2.5 mg / L.

Embodiment 3

[0053] Example 3: The device can still refer to Example 1 and Appendix figure 1 , Using its process to treat the middle-stage wastewater of alkaline wheat straw pulp, the steps are as follows:

[0054] (1) Wastewater pretreatment: remove the large floating suspended solids in the wastewater that can easily block pumps and pipelines, and recover longer fibers for comprehensive utilization;

[0055] (2) Pre-oxidation treatment: The pre-treated wastewater is adjusted to pH 3-5 with acid. Under the action of Fenton reagent, the organic matter is decomposed and most of COD is removed Cr And chromaticity, the effluent is added with alkali to adjust the pH to 6-7, then the suspended solids in the wastewater are removed under the action of the coagulant, and the pre-oxidation process is completed after solid-liquid separation;

[0056] (3) Aerobic biological treatment: the wastewater undergoes the adsorption, oxidation, and degradation of aerobic microorganisms to remove most of the organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com