Processing aids for enhanced hydrocarbon recovery from oil sands, oil shale and other petroleum residues

a technology of processing aids and hydrocarbon recovery, which is applied in the field of recovery of hydrocarbons from tar sands, oil shale and other petroleum residues, can solve the problems of complex process of separating bitumen from sand, clay and water, increasing the loss of bitumen to waste streams, and reducing the yield of bitumen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

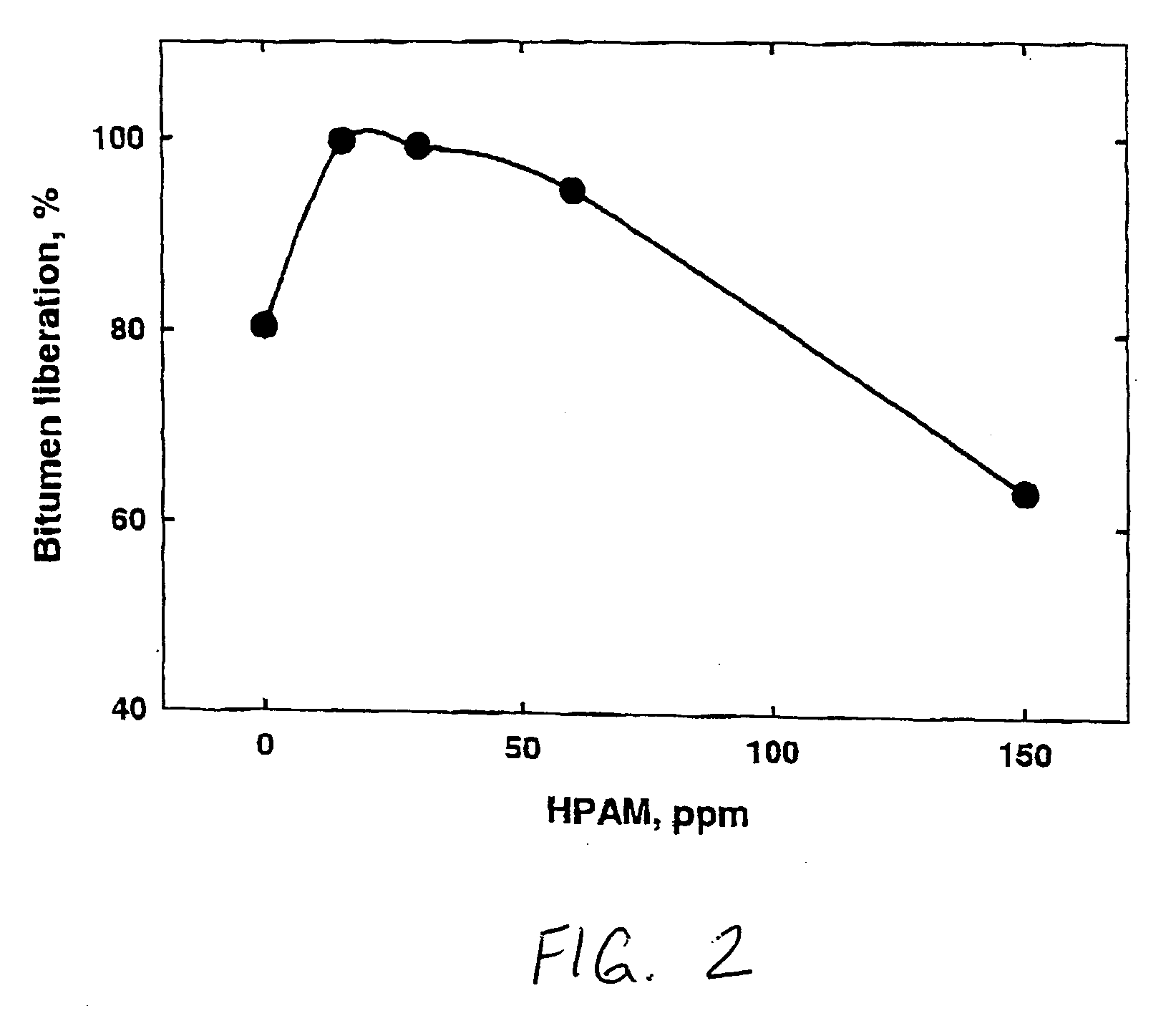

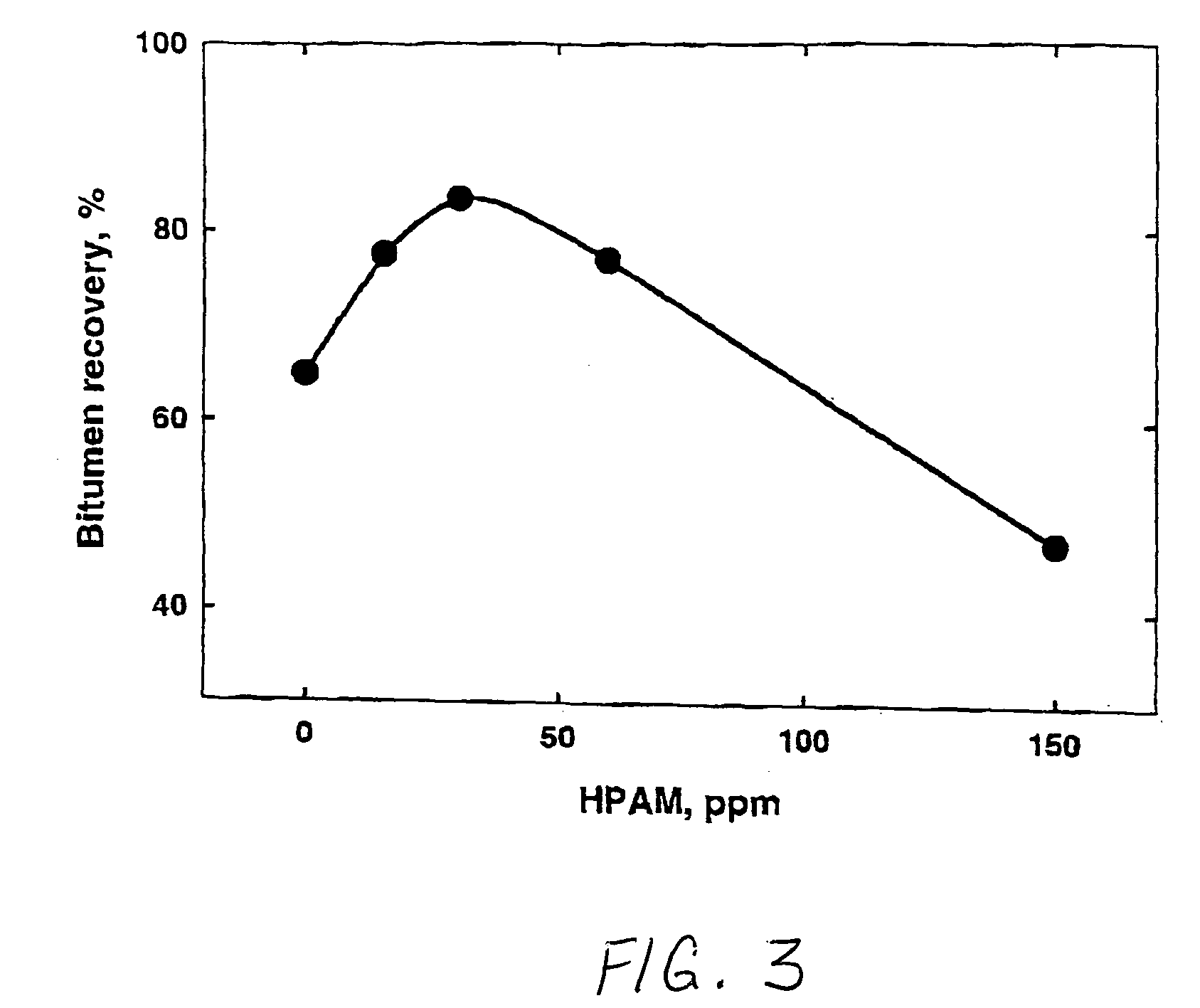

Bitumen Yields Using a Polymeric Hydrolysed Polyacrylamide Processing Aid

[0079] Bitumen extraction experiments were conducted in a laboratory hydrotransport extraction system capable of simulating commercial production conditions. Two CCD (charge coupled device) cameras were used for on-line monitoring of bitumen liberation and bubble surface loading, respectively, and a computer automatically recorded the signals.

[0080] Samples of oil sands, called transition ore that is one of poor processing ores, and Aurora recycle process water were obtained from an Aurora commercial plant operated by Syncrude Canada Ltd. The bulk ore sample was homogenized, packed in 600 g plastic bags and stored in a freezer at −29° C. to prevent oxidation. This ore sample consisted of 9.2 wt % bitumen, 7.3 wt % water and 83.5 wt % solids. The solids contain 33% clay fines (less than 44 um in size). The water used for the bitumen extraction experiments is called Aurora process water. Atomic absorption spect...

example 2

Tailings Settling Using a Polymeric Hydrolysed Polyacrylamide Processing Aid

[0088] Tailings samples taken directly from the bitumen extraction experiments of Example 1, with or without chemical addition, were used to conduct settling tests in closed cylinders. The descent of the solid / solution interface (mud line) was recorded as a function of time. A plot of the thickness of the supernatant layer versus time was used to determine the initial settling rate from the slope of the initial linear portion of the plot.

[0089] A Nanoscope E atomic force microscope (AFM) with a fluid cell was used for the surface force measurements. Force measurements were performed in the fluid cell where a colloidal probe (a silica sphere or a clay fine particle) interacted with a flat silica plate or a bitumen surface in various tailings waters taken from bitumen extraction experiments as soon as a clean layer of water was available. All force measurements were conducted after an incubation time of 30 m...

example 3

Effect of a Polymeric Hydrolysed Polyacrylamide Processing Aid on the Concentration of Divalent Cations in Process Water

[0091] A sample of Aurora process water at a pH of 8.5 was obtained and divided into four equal aliquots. Three of the aliquots received a treatment with HPAM at dosages of 15, 45 and 150 mg / L, respectively. The fourth aliquot was not treated. The concentrations of calcium ions (Ca++) and magnesium ions (Mg++) in each of the aliquots were measured using an Atomic Absorption Spectrometer and the results are plotted in the graph of FIG. 5. The untreated aliquot showed that the process water had initial calcium and magnesium ion concentrations of 39 ppm and 13 ppm, respectively. The treated aliquots showed a linear reduction of both calcium and magnesium ions with increasing HPAM concentration over the range investigated. The reduction of calcium and magnesium ion concentrations indicates ion intake by HPAM. It is believed that this ion absorption not only improves b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com