Rotary kiln type incinerator capable of improving sufficient burning of garbage materials

A full combustion and incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of only sliding on the inner wall of the kiln, not fully combusting, burning out waste, etc., to reduce slag emissions , convenient maintenance, improve the effect of incineration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

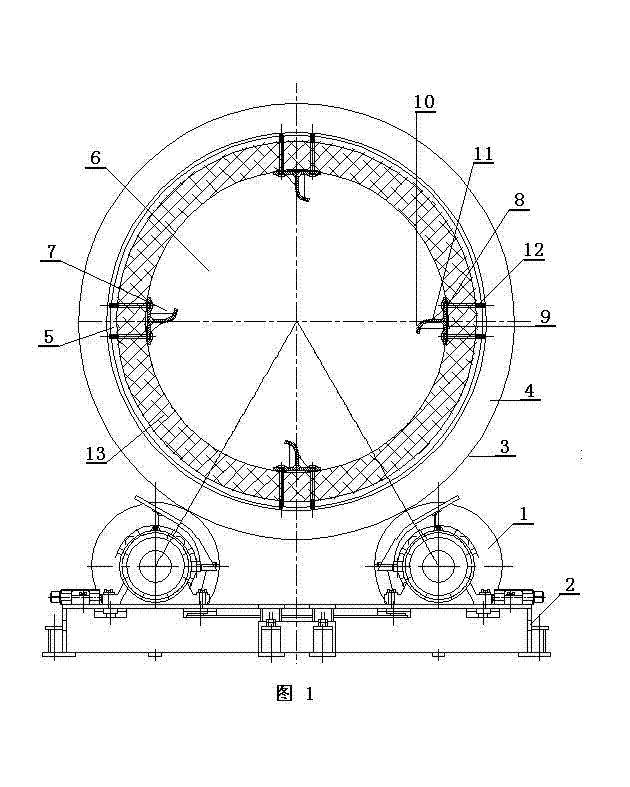

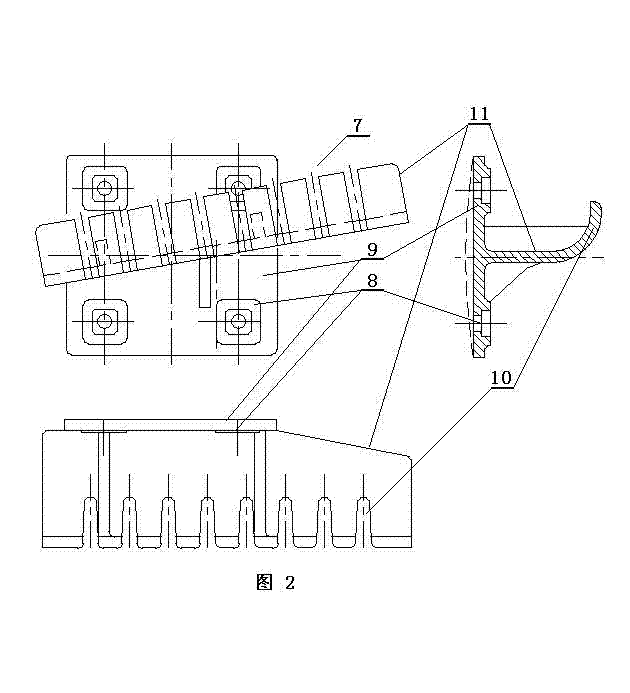

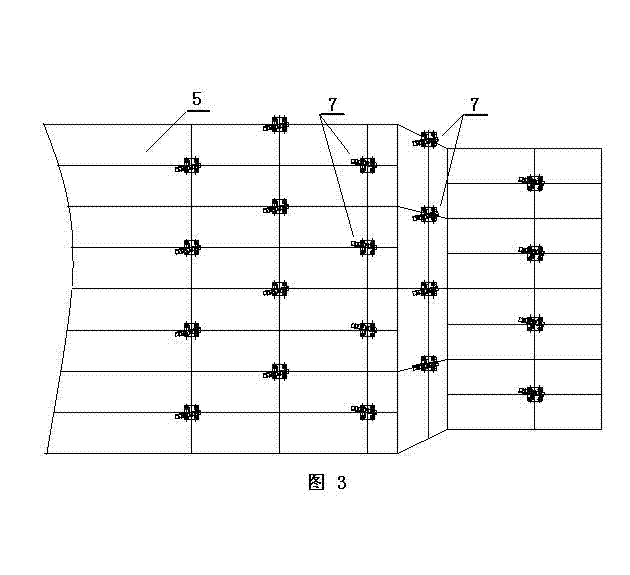

[0017] exist figure 1 , figure 2 and image 3 Among them, the main body of the rotary kiln type incinerator capable of strengthening the full combustion of garbage materials of the present invention includes a support 2 with a power drive mechanism 1, a cylinder lying on the support 2 obliquely and driven to rotate on the support 2 shaped kiln body 3, the kiln body shell 4 is rolled and welded by carbon structural steel plate, refractory material 13 is arranged on the kiln body wall 5, and the kiln body cavity 6 is a waste material incineration chamber, which is characterized in that the kiln body wall 5 There is a lifting plate 7 that is helpful for turning over, tearing and loosening the garbage materials, wherein: the lifting plate 7 is made of high-temperature resistant metal material, in the shape of a rake, and has a limit assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com