Simple trash remover for trash rack

A technology of a trash rack and a trash cleaning machine, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of inconvenient use, inconvenient maintenance, and high manufacturing costs, and achieve convenient use, simple structure, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

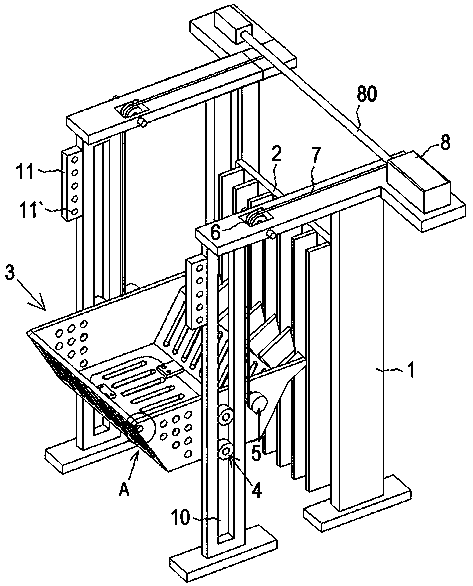

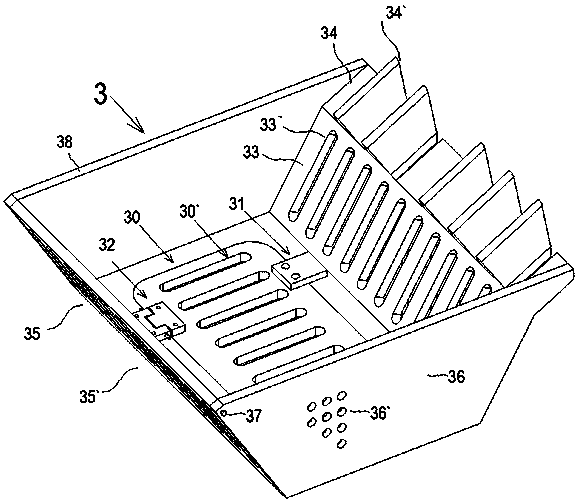

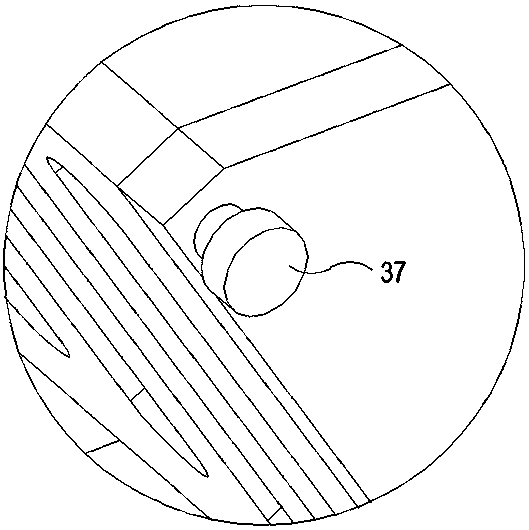

[0021] see figure 1 , the present invention provides 1 a kind of simple cleaning machine that is used for trash rack, comprises frame 1, and the rear side of described frame 1 is provided with trash rack 2, and the front side is slidably provided with the cleaning machine that can lift up and down. The rake bucket 3 is provided with a driving device for driving the cleaning rake bucket 3 up and down. The cleaning rake bucket 3 is an inverted trapezoidal box with an open upper side, and a hole is provided in the lower part of the hole, and a movable The overturned flap 30; the right waist plate 33 of the cleaning rake bucket 3 near the side of the trash rack 2 is provided with a rake tooth part 34 that is integrally formed and forms an angle of 120° with the right waist plate 33. The rake tooth part 34 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com