Tea roasting device for tea leaf processing

A technology for roasting tea and tea leaves, which is applied in the field of roasting tea equipment for tea processing, which can solve the problems of general drying uniformity of tea leaves, and achieve the effects of improving heat conduction efficiency, stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

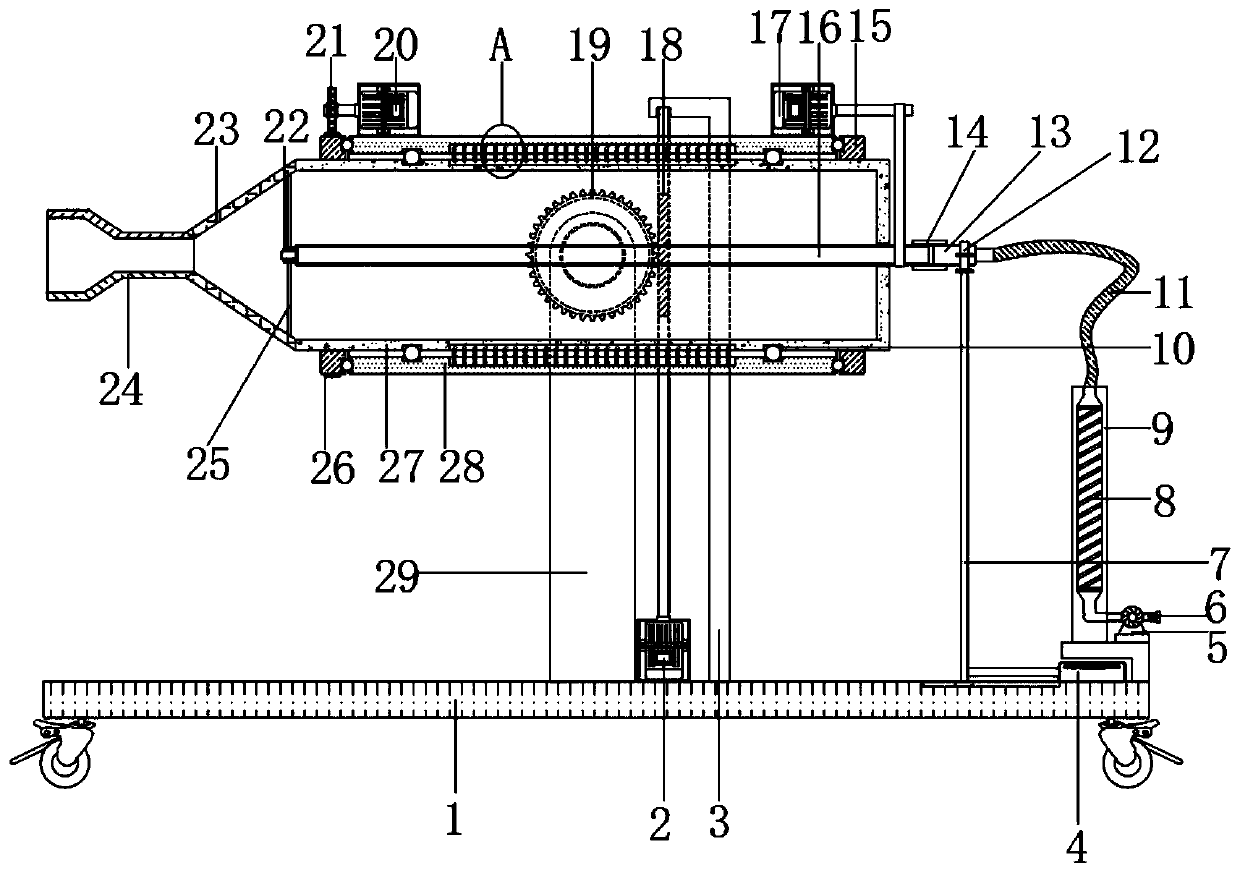

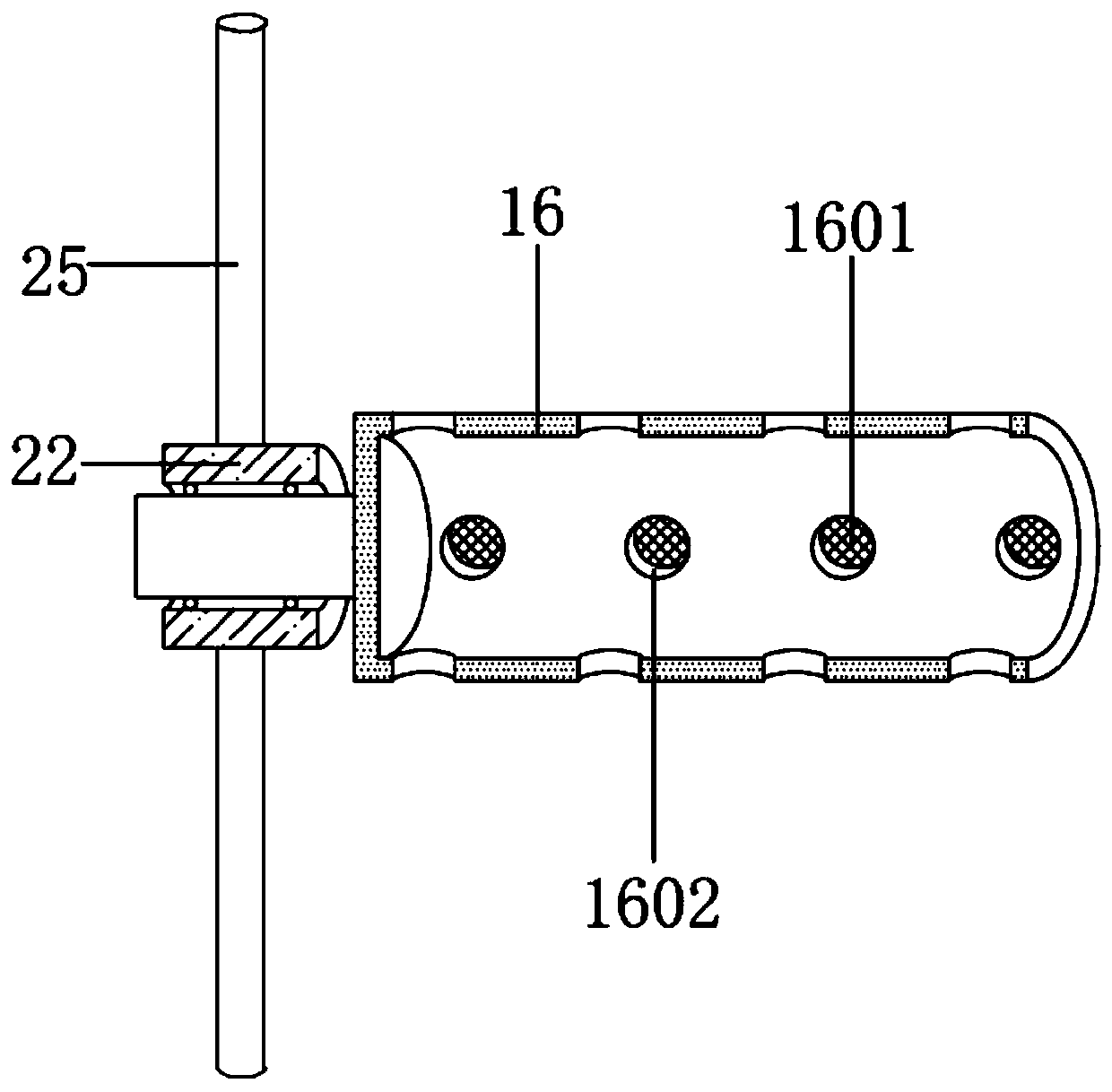

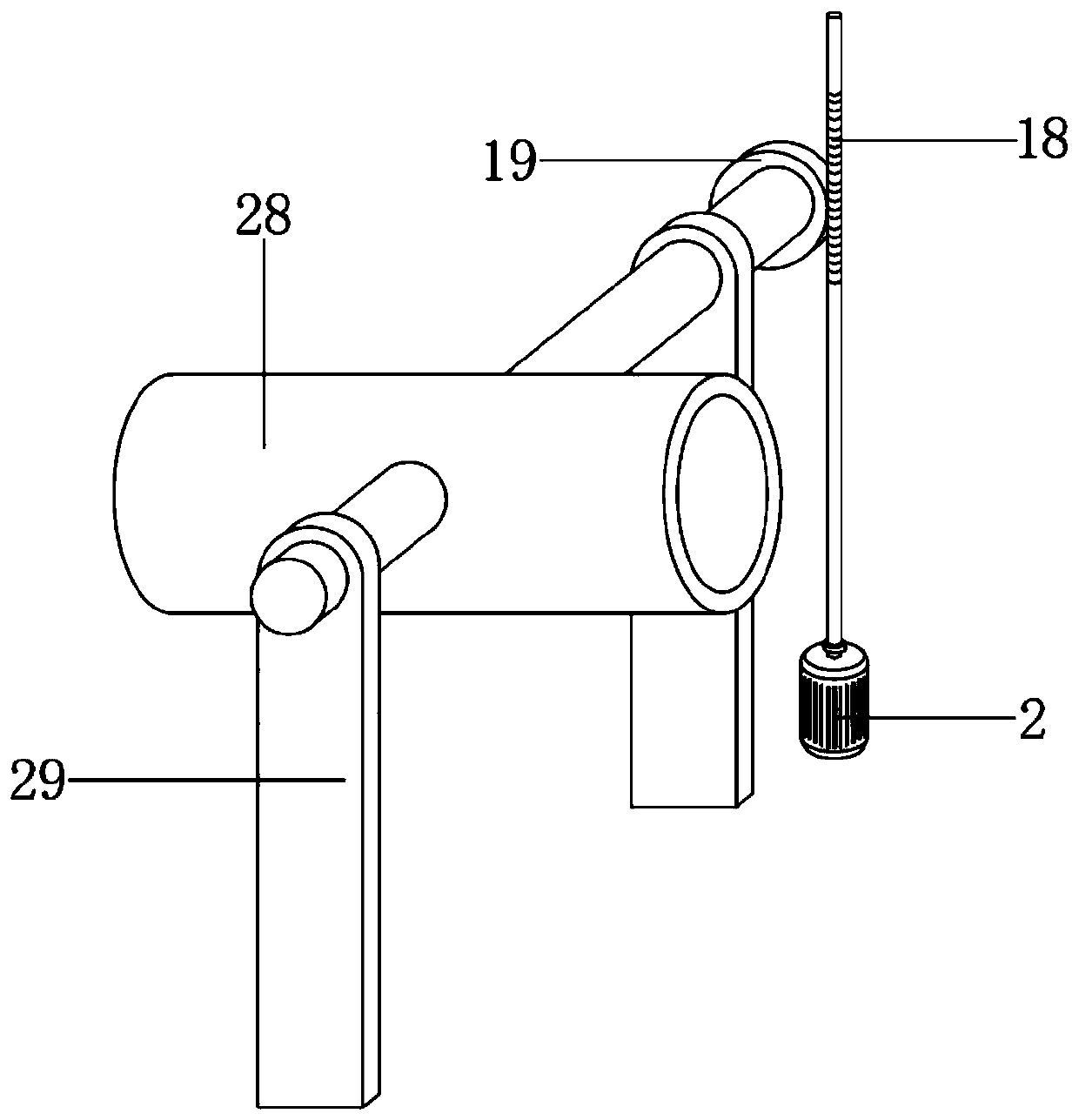

[0030] refer to Figure 1-4 , a roasted tea device for tea processing, comprising a base 1 with brake wheels welded at the four corners of the outer wall of the bottom, brackets 29 are vertically welded on both sides of the top outer wall of the base 1, and the opposite sides of the two brackets 29 are rotatably connected with The same turning drum 28, the inside of the turning drum 28 is provided with a built-in drum 27, and the outer walls of the two ends of the built-in drum 27 are welded with ring plates 15. There are annular grooves 10 on both sides, and the inner walls corresponding to the two annular grooves 10 are equidistantly rolled and connected with balls distributed equidistantly. The inner walls of the upper and lower ends of the turning cylinder 28 and the opposite side of the built-in rotating cylinder 27 are respectively provided with mounting grooves. And the barrel groove, and the inner wall of the installation groove is fixedly equipped with resistance heat...

Embodiment 2

[0041] refer to Figure 5 , a roasted tea device for tea processing. Compared with Embodiment 1, this embodiment also includes that the inner wall of the circumference of the built-in drum 27 is welded with baffles 33 equidistant and annularly distributed.

[0042] When the present invention is used: the baffle 33 is provided on the inner wall of the built-in drum 27, and the baffle 33 can be used to hold up the tea leaves during the rotation of the built-in drum 27, thereby improving the turning effect of the tea leaves and ensuring the drying effect of the tea leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com