Three-dimensional hollow tube microarray framework catalyst and method of using same to prepare beta-phenylethanol

A three-dimensional hollow, catalyst technology, used in oxidation reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor catalyst structure and performance, reduced catalyst life, difficult product separation, etc., to simplify products. The effect of separation process, extended life, and improved process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

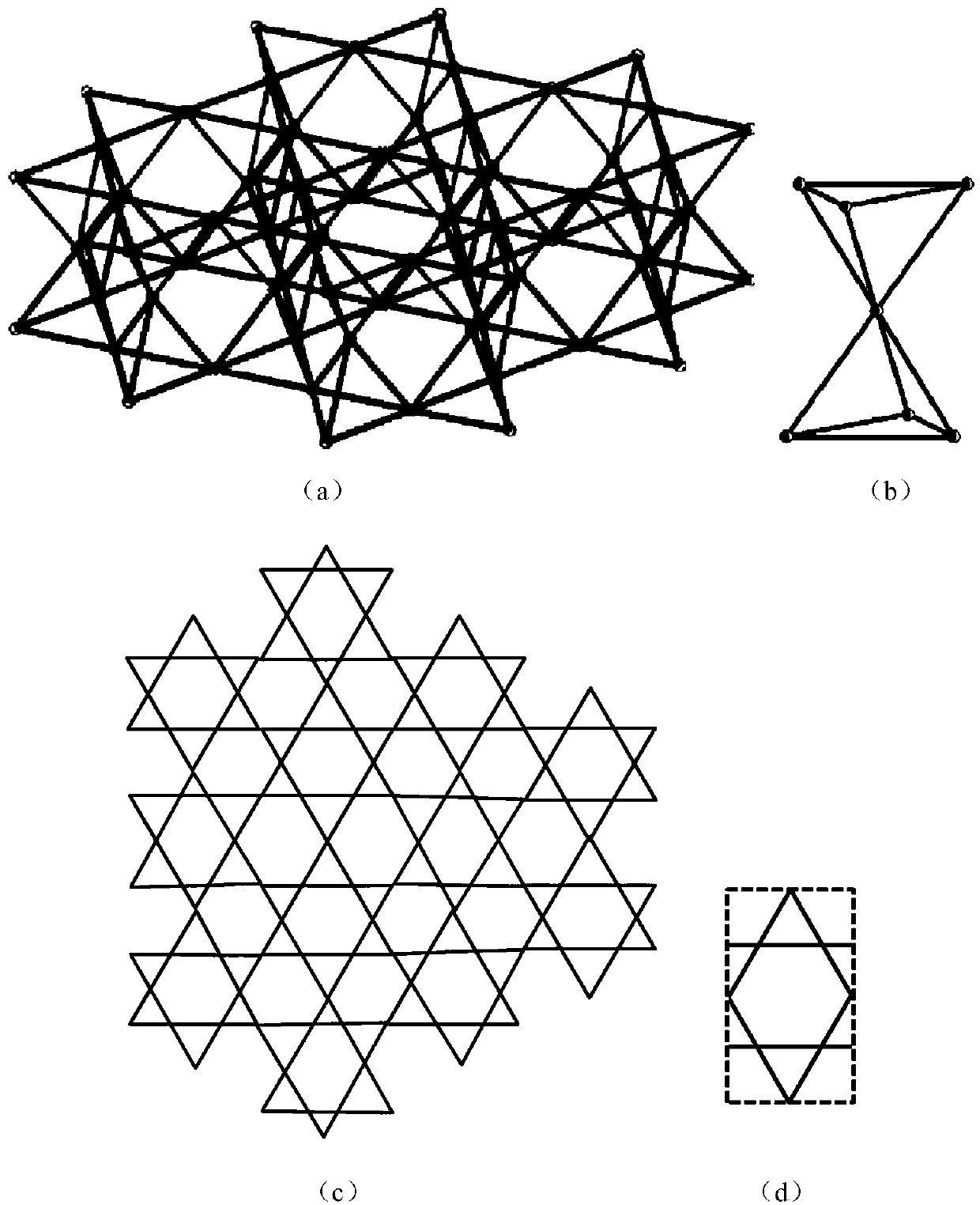

Embodiment 1

[0045] The preparation of the catalyst was carried out on the FS271M selective laser melting (SLM) molding equipment (Hunan Farsoon High-Tech Co., Ltd.), the alloy powder (provided by Falcon Rapid Manufacturing Co., Ltd.) had a particle size of 15 μm, and the Ni content of the alloy powder was 45.3 wt%. , Al content 50.8wt%, Cr content 2.7wt%, Mo content 1.2wt%, processed into a three-dimensional Kagome grid structure, its cells are formed by connecting two regular tetrahedrons to the top, and the SLM forming process parameters are set as: The Kogome cell side length is 300 μm, the hollow tube diameter is 100 μm, the hollow tube wall thickness is 10 μm, the block size is 100mm*100mm*100mm, the laser power is 150W, the spot diameter is 80μm, the scanning speed is 15m / s, and the scanning distance is 0.45mm.

[0046] The obtained catalyst is CAT-1.

Embodiment 2

[0048] The preparation of the catalyst was carried out on the FS271M selective laser melting (SLM) molding equipment (Hunan Farsoon High-Tech Co., Ltd.), the alloy powder (provided by Falcon Rapid Manufacturing Co., Ltd.) had a particle size of 45 μm, and the Ni content of the alloy powder was 54.7wt%. , Al content 36.2wt%, Cr content 5.9wt%, Cu content wt3.2%, processed into a three-dimensional Kagome grid structure, its cells are formed by connecting two regular tetrahedrons to the top, and the SLM forming process parameters are set as : Kogome cell side length 550μm, hollow tube diameter 50μm, hollow tube wall thickness 20μm, block size 150mm*150mm*150mm, laser power 500W, spot diameter 220μm, scanning speed 35m / s, scanning distance 0.1mm .

[0049] The obtained catalyst is CAT-2.

Embodiment 3

[0051] The preparation of the catalyst was carried out on the FS271M selective laser melting (SLM) molding equipment (Hunan Farsoon High-Tech Co., Ltd.), the alloy powder (provided by Falcon Rapid Manufacturing Co., Ltd.) had a particle size of 30 μm, and the Ni content of the alloy powder was 50.6wt%. , Al content 45.1wt%, Mo content 4.3wt%, processed into a three-dimensional Kagome grid structure, its cells are formed by connecting two regular tetrahedrons to the top, the SLM forming process parameters are set as: Kogome cell side length 245μm , the diameter of the hollow tube is 15 μm, the wall thickness of the hollow tube is 2.5 μm, the block size is 50mm*50mm*50mm, the laser power is 425W, the spot diameter is 150μm, the scanning speed is 25m / s, and the scanning distance is 0.25mm.

[0052] The obtained catalyst is CAT-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com