Method for increasing content of beta-phenethyl alcohol in yellow rice wine

A technology of phenylethyl alcohol and rice wine, applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of ineffective improvement of rice wine flavor and quality, low content of β-phenylethyl alcohol, etc., and achieve The effect of increasing the content, increasing the total sugar content, and improving the ability of ester production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

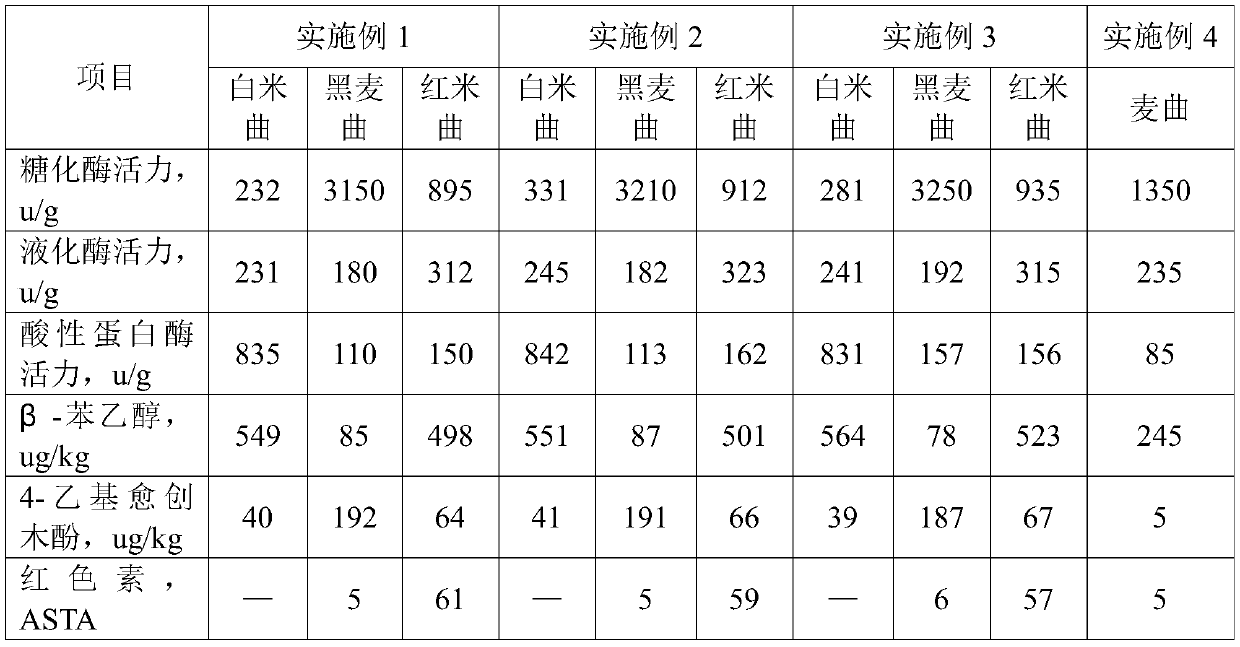

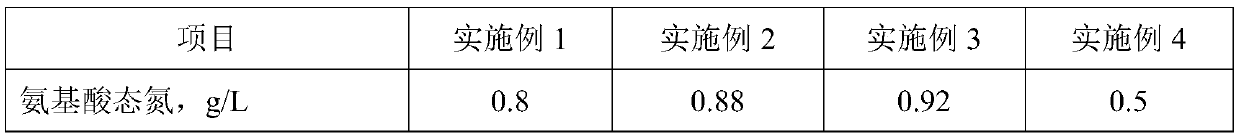

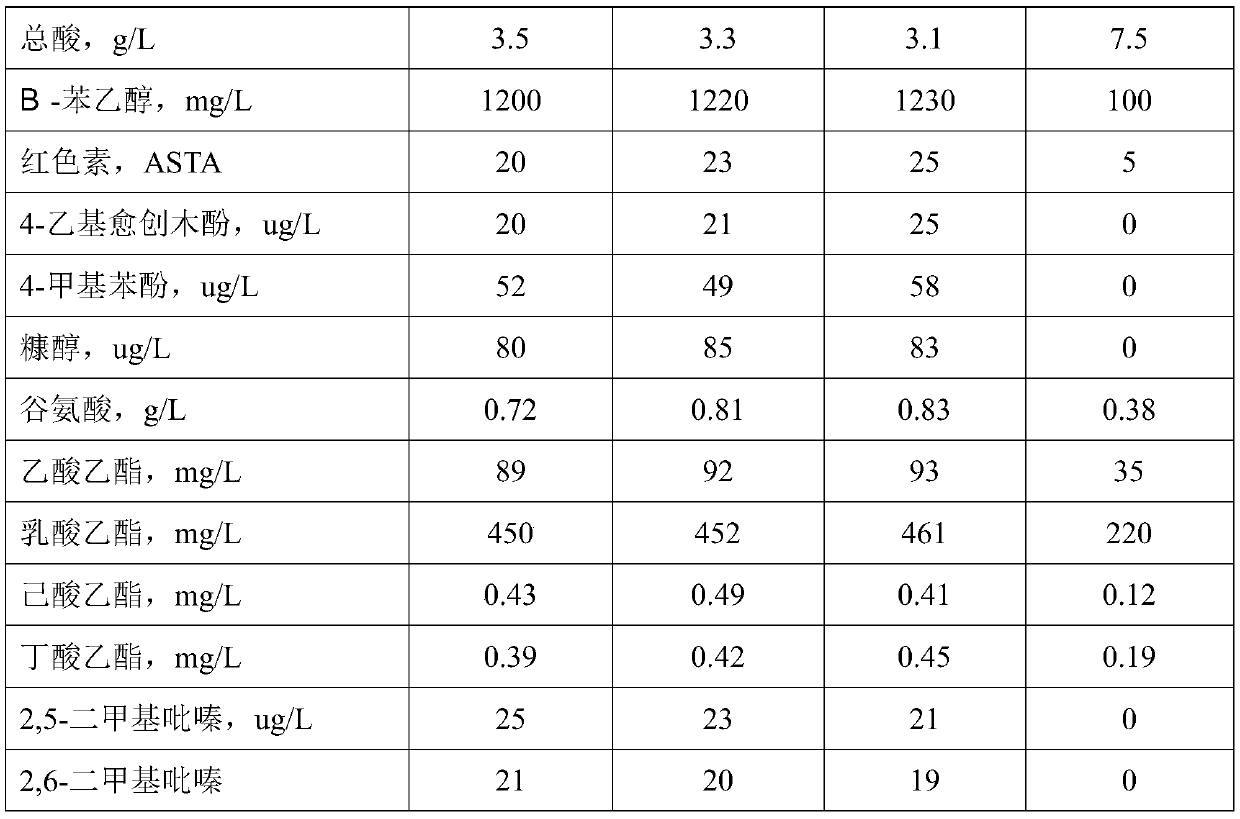

Embodiment 1

[0033] A kind of method of improving rice wine β-phenylethanol content of the present invention comprises the following steps:

[0034] (1) Raw material processing: add rice, barley, and glutinous rice to tap water at a temperature of 50°C, soak for 2 hours, drain the open water, cook under pressure at a temperature of 125°C, a pressure of 0.15Mpa, for 8 minutes, cool the steamed rice to 15°C, and steam The cooked barley is cooled to 65°C, and the steamed glutinous rice is cooled to 30°C. Wheat is passed through a wheat frying machine at 135°C for 15s, cooled to 40°C, and pressed into 4 pieces with a roller press for later use.

[0035] (2) Cultivation of white rice koji: Mix the steamed and cooled rice with fried and crushed wheat at a weight ratio of 1:1, then add 0.2% of white Aspergillus powder and mix evenly, put it in a koji box and step on it to make white brick koji , 5kg in each brick koji, placed in a single layer in a constant temperature room at 15°C for low tempe...

Embodiment 2

[0050] A kind of method of the present invention improves rice wine cooking wine β-phenylethanol content, comprises the following steps:

[0051] (1) Raw material processing: add rice, barley, and glutinous rice to tap water at a temperature of 55°C, soak for 1 hour, drain the open water, cook under pressure at a temperature of 128°C, a pressure of 0.18Mpa, for 6 minutes, cool the steamed rice to 18°C, and steam The cooked barley is cooled to 68°C, and the steamed glutinous rice is cooled to 33°C. The wheat is cooled to 43°C through a wheat frying machine at 138°C for 13s, and pressed into 5 pieces with a roller press for later use.

[0052] (2) Cultivation of white rice koji: Mix the steamed and cooled rice with fried and crushed wheat at a weight ratio of 1:2, then add 0.4% of white Aspergillus powder and mix evenly, put it in a koji box and step on it to make white brick koji , 7kg in each brick koji, placed in a single layer in a constant temperature room at 18°C for 40...

Embodiment 3

[0065] A kind of method of the present invention improves rice wine cooking wine β-phenylethanol content, comprises the following steps:

[0066] (1) Raw material processing: add rice, barley, and glutinous rice to tap water at a temperature of 60°C, soak for 1 hour, drain the open water, cook under pressure at a temperature of 130°C, a pressure of 0.20Mpa, for 5 minutes, cool the steamed rice to 20°C, and steam The cooked barley is cooled to 70°C, and the steamed glutinous rice is cooled to 35°C. Wheat is passed through a wheat frying machine at 140°C for 10s, cooled to 45°C, and pressed into 6 pieces with a roller press for later use.

[0067] (2) Cultivation of white rice koji: Mix the steamed and cooled rice with fried and crushed wheat in a weight ratio of 1:3, then add 0.5% of white Aspergillus powder and mix evenly, put it in a koji box and step on it to make white brick koji , 8kg in each brick koji, placed in a single layer in a constant temperature room at 20°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com