Yellow liquor from white granulated sugar and making method thereof

A technology for white granulated sugar and rice wine, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of short shelf life of finished rice wine, heavy bitterness and astringency of rice wine, slow filtration speed, etc. Achieving zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Falling into the tank: Add 250g of white sugar for the first time, then add 40g of wheat koji, 150g of distiller's mother and 1930g of water, stir evenly and then fall into the tank, the temperature of the tank is controlled at 28°C;

[0034] 2) Opening rake: After the above materials are fermented in the tank for 12 hours, use compressed air to ventilate the opening rake in time, and the fermentation temperature is controlled below 29°C;

[0035] 3) Second feeding: after 24 hours of fermentation, add 250g of white sugar for the second time, stir evenly with compressed air, after 12 hours of fermentation, ventilate and stir with compressed air;

[0036] 4) Three feeds: after 24 hours of fermentation, add 100g of white sugar for the third time and stir evenly with compressed air;

[0037] 5) Post-fermentation: During the period, compressed air is used to open rakes every day for 9 days, and the temperature is controlled at 25-29°C;

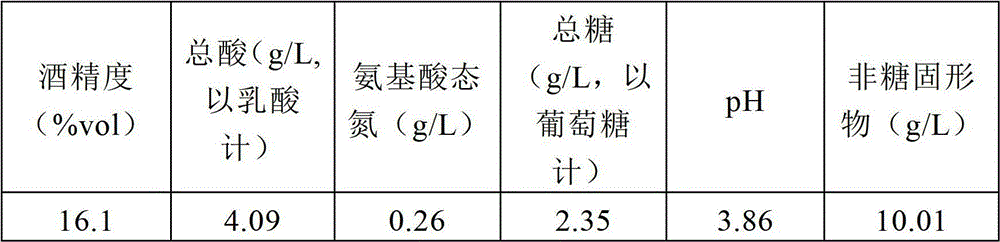

[0038] 6) Press filtration and cl...

Embodiment 2

[0044] 1) Falling into the tank: put 800g of white sugar for the first time, then add 150g of wheat koji, 400g of distiller's mother and 4800g of mixed water produced by mixing acid rice milk water produced in the traditional rice wine brewing process with clear water. The total acid of the mixed water is 2.7g / L. Stir evenly and drop into the tank, the temperature of the tank is controlled at 27°C;

[0045] 2) Opening rake: After the above materials are fermented in the tank for 12 hours, use compressed air to ventilate the opening rake in time, and the fermentation temperature is controlled below 30°C;

[0046] 3) Second feeding: after 24 hours of fermentation, add 700g of white sugar for the second time, stir evenly with compressed air, after 12 hours of fermentation, ventilate and stir with compressed air;

[0047] 4) Three feeds: after 24 hours of fermentation, add 300g of white sugar for the third time and stir evenly with compressed air;

[0048] 5) Post-fermentation:...

Embodiment 3

[0055] 1) Falling into the tank: Add 10kg of white sugar for the first time, then add 1.7kg of wheat koji, 5kg of distiller's mother and 65kg of water, stir evenly and then fall into the tank, the temperature of the tank is controlled at 27°C;

[0056] 2) Opening rake: After the above materials are fermented in the tank for 12 hours, use compressed air to ventilate the opening rake in time, and the fermentation temperature is controlled below 30°C;

[0057] 3) Secondary feeding: After 24 hours of fermentation, add 9kg of white sugar for the second time, stir evenly with compressed air, after 12 hours of fermentation, ventilate and stir with compressed air;

[0058] 4) Three feeds: after 24 hours of fermentation, add 4kg of white sugar for the third time and stir evenly with compressed air;

[0059] 5) Post-fermentation: During the period, use compressed air to rake every day for 15 days, and the temperature is controlled at 20-24°C;

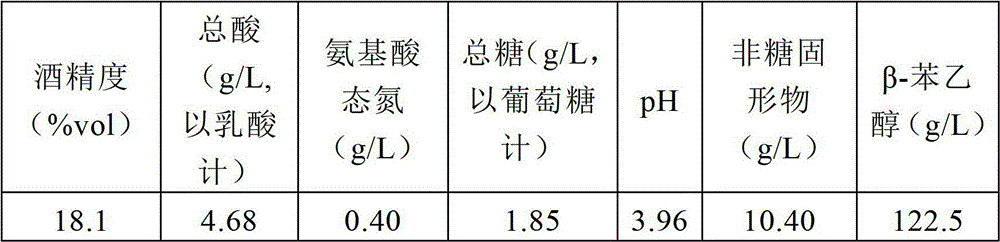

[0060] 6) Press filtration and clarificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com