Preparation method for novel suckercide

A sprouting inhibitor and a new type of technology are applied in the field of biological new sprouting inhibitor preparation, which can solve the problems of large investment in production equipment, complicated fermentation process, and many waste water and residues, and achieve low production cost, high concentration, and no environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a kind of preparation method of novel sprout inhibitor, comprises the following steps:

[0030] 1) Specimen collection: First collect the diseased specimens of Botrytis Cinerea Persr fungus CGMCC NO0357-1 from the plants. The fungus was preserved in the General Microbiology Center of China Committee for the Collection of Microbial Cultures in 1998. Fresh specimens with typical symptoms were selected for surface treatment. Disinfection, after rinsing with sterilized water, use tissue separation or direct spore shake-off method to separate and purify single spores;

[0031] 2) Then culture the purified cultured strains in the culture medium. Under the condition of the temperature of the incubator at 24°C, the PDA medium is used for 48 hours. Peptone, its parts by weight are: 2:2:20:1;

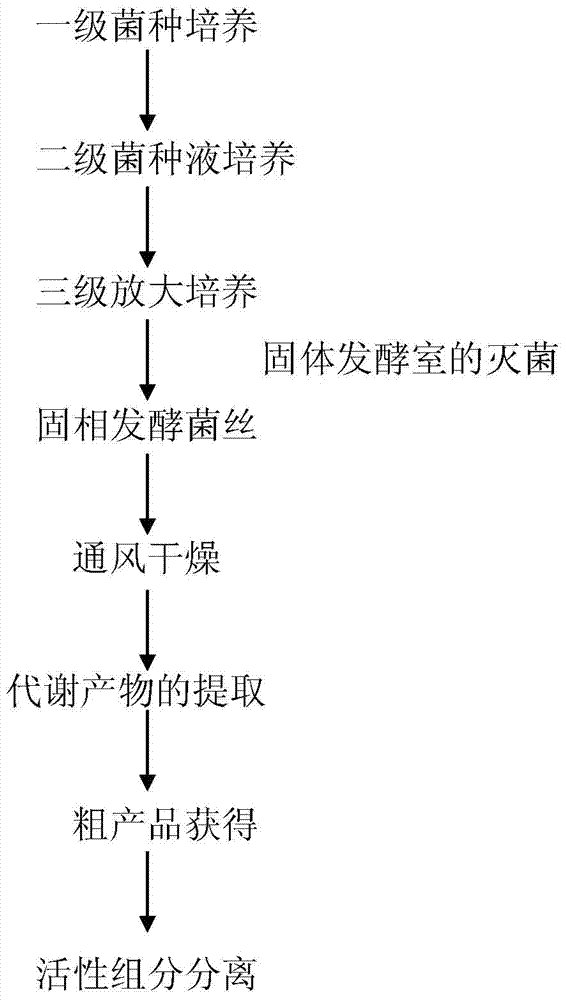

[0032] 3) if figure 1 As shown, the following solid fermentation procedure is carried out:

[0033] Primary strain cultivation: Under the condition of aseptic ope...

Embodiment 2

[0043] Except for step 2), the specific preparation steps are the same as in Example 1. The medium used in step 2) is a seed liquid medium, and the medium includes sucrose, peeled potatoes, and peptone, and the weight parts are: 2, 20 ,1.

Embodiment 3

[0045] Except for step 2), the specific preparation steps are the same as in Example 1. The medium used in step 2) is a seed tank medium or a pilot medium, and the medium includes wheat bran, peptone, sucrose, urea, chlorinated Potassium, magnesium sulfate heptahydrate, potassium dihydrogen phosphate, ferrous sulfate heptahydrate, manganese sulfate, sodium nitrate, peanut oil, defoamer, its parts by weight are: 10, 0.05, 1.5, 0.08, 0.0325, 0.0325, 0.0525, 0.00137, 0.0075, 0.0075, 0.2, 0.03, adjust the pH value to about 8.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com