Method for purification of ss-phenylethyl alcohol

A kind of purification method, the technology of phenethyl alcohol, be applied in the purification field of following β-phenethyl alcohol, can solve the problems such as unfavorable economy, no oxidation reaction etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

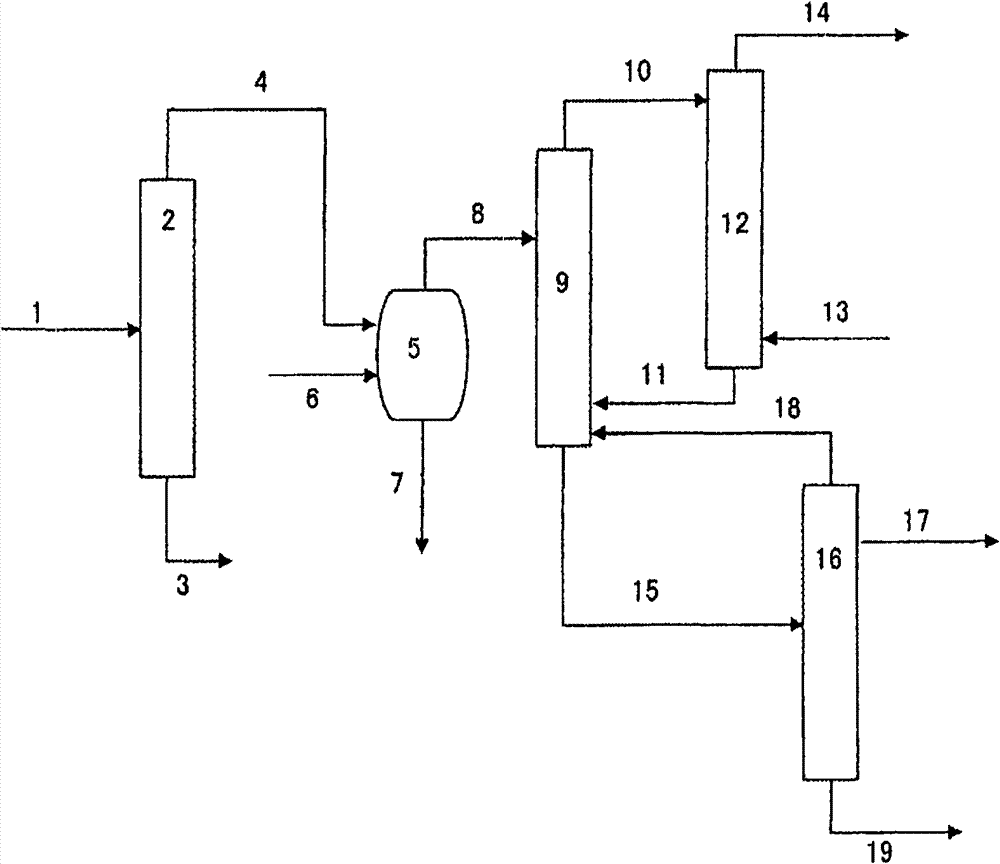

[0041] Contain the thick beta-phenylethanol of 67.1% (weight) beta-phenylethanol with the speed supply of 425.4kg / hour by supply pipe (1), take out distillation and separation heavy matter with the speed of 310.9kg / hour by drain pipe (4) again For the separated liquid, the above-mentioned supply pipe (1) is arranged on the twelfth stage counted from the top of the heavy separation column (2). The number of sections of the heavy separation column (2) is 33 sections, the top pressure is 29.3kPa, and the reflux ratio is 3.9. The thick β-phenylethanol that will pass through the heavy separation step is supplied to alkali cleaning tank (5), and it is 25% to supply sodium hydroxide concentration in the alkali cleaning tank (5) with the speed of 62.9kg / hour by supply pipe (6) simultaneously (weight) of alkaline water. In order to improve the cleaning efficiency, the alkali cleaning tank (5) uses a reactor with built-in rotating paddles and operates at a temperature of 80° C. and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com