Saccharomyces Cerevisiae strain with high yield of beta-phenylethanol and application thereof

A technology of Saccharomyces cerevisiae strain and phenylethyl alcohol, which is applied in the directions of fungi, vinegar preparation, alcoholic beverage preparation, etc., can solve problems such as unclear alcohol production capacity of strains, and achieve the effect of good alcohol production characteristics and high alcohol production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

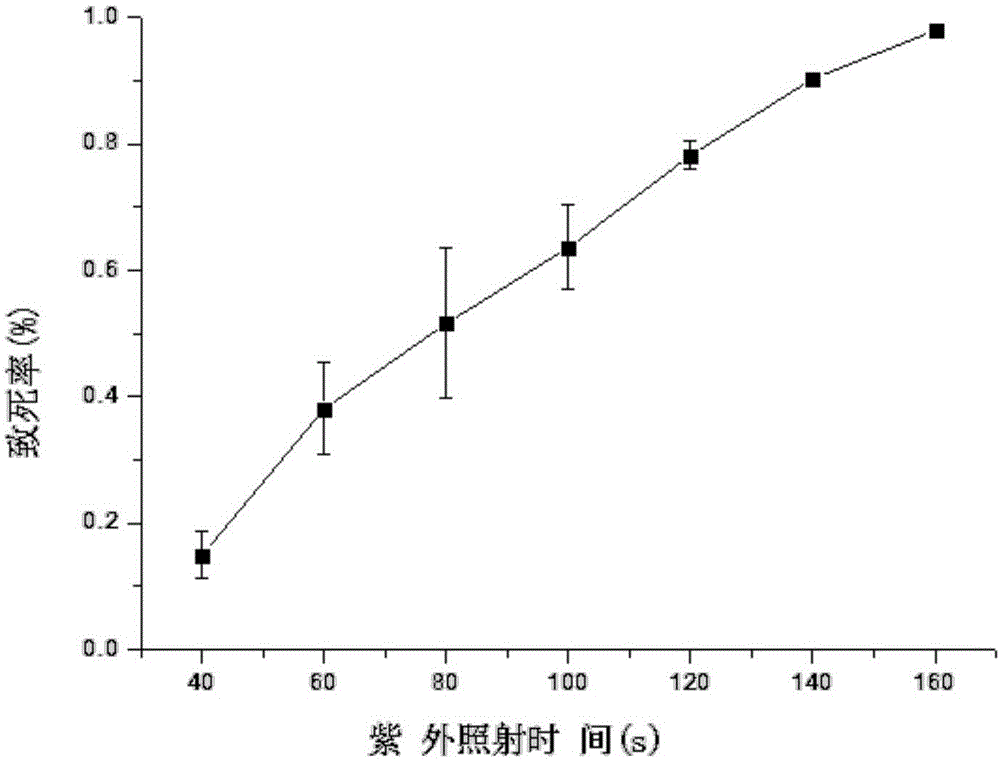

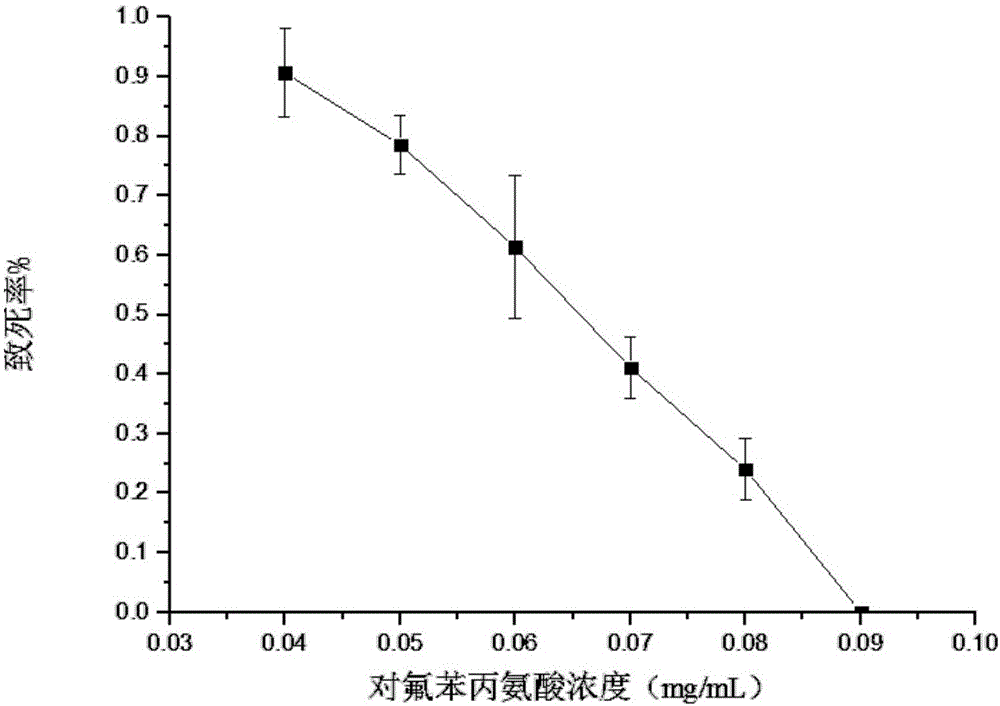

[0052] Embodiment 1: UV mutagenesis and screening

[0053] YPD liquid medium: yeast extract 10g / L, fish meal peptone 20g / L, glucose 20g / L.

[0054] YPD solid medium: yeast extract 10g / L, fish meal peptone 20g / L, glucose 20g / L, nutrient agar 20g / L.

[0055] 1. Obtaining the starting strain for mutagenesis

[0056] (1) Take 200 ul of Saccharomyces cerevisiae liquid screened from rice wine mash by our laboratory from the glycerin storage tube, spread it on a YPD plate, and incubate at 30°C for 24 hours.

[0057] (2) Use an inoculation loop to pick a single colony into a shake flask containing 100 ml of YPD liquid medium, and culture it at 30° C. and 200 r / min for 24 hours.

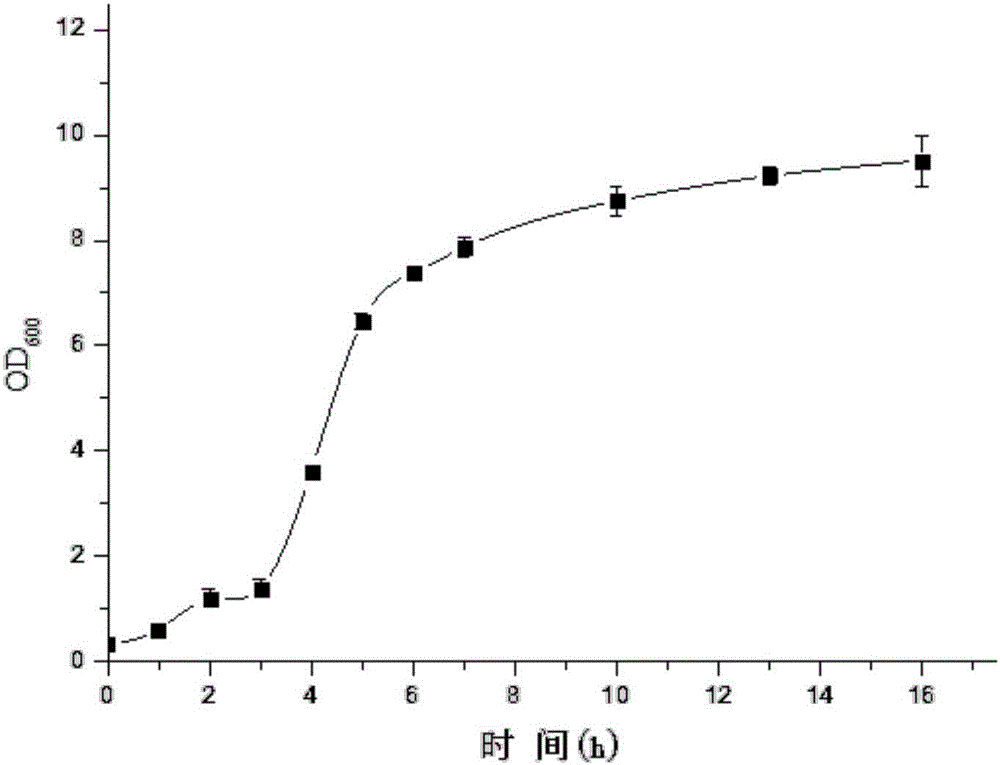

[0058] (3) Take 5ml of the obtained bacterial solution, inoculate it into a shake flask containing 100ml of YPD liquid medium, cultivate it at 30°C and 200r / min, measure the OD600 of the bacterial solution every 1h, and measure the OD600 every 3h after the end of the yeast exponential growth period, Three ...

Embodiment 2

[0098] Embodiment 2: Isobaric plasma mutagenesis and screening at room temperature

[0099] 1. Plasma mutagenesis at room temperature and isobaric pressure and fermentation screening of rice wine simulated liquor

[0100] After the first round of ultraviolet mutagenesis, the selected strain 1-e4 was used as the starting strain for normal temperature and isobaric plasma mutagenesis. The 1-e4 strains were cultured in YPD shake flasks at 30°C for 24 hours, and a bacterial suspension with an OD600 of 0.6-0.8 was prepared with physiological saline, and subjected to isobaric plasma mutagenesis at room temperature. The mutagenesis time was 60s and the power was 100w. Resuspend the bacterial solution, spread it on a YPD plate, incubate at 30°C for 48 hours, and streak a single colony onto a YNBP plate (the concentration of p-fluorophenylalanine is 0.5g / L). Fermentation screening. Determination of β-phenylethanol content in yellow rice wine simulant liquid by high performance liquid ...

Embodiment 3

[0123] Embodiment 3: the application of high-yielding β-phenylethanol yeast in yellow rice wine

[0124] 1. Rice wine brewing process 1

[0125] (1) Production of distiller's yeast: 50mLYPD shake flask was inoculated with yeast strain, cultured at 30°C and 200r / min for 24h. Add 1L of water and 0.05kg of wheat koji to 1kg of steamed rice (moisture content 70%), stir evenly, keep warm at 60°C for 4h, inoculate yeast solution at 5% after cooling, and cultivate for 16h at 30°C and 200r / min; Saccharomyces cerevisiae BYC3 (CCTCC NO: M2016785) with high β-phenylethanol production.

[0126] (2) Steam cooked rice (moisture content 70%), add equal weight of clear water, 2% wheat koji, 5% distiller's mother, and stir evenly.

[0127] (3) Fermentation and stirring: the fermentation temperature is 28°C, start timing after the blanking is completed, stir every 8 hours, and stir 6 times in 48 hours. Ferment for 5-7 days, and finish the fermentation when the alcohol index no longer rises. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com