Method for extracting agaric polysaccharides

A technology of fungus polysaccharides and fungus, applied in the biological field, can solve the problems of long extraction time, complicated extraction process, and large amount of extraction solution, and achieve the effects of avoiding loss of activity, rapid extraction, and reduced concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

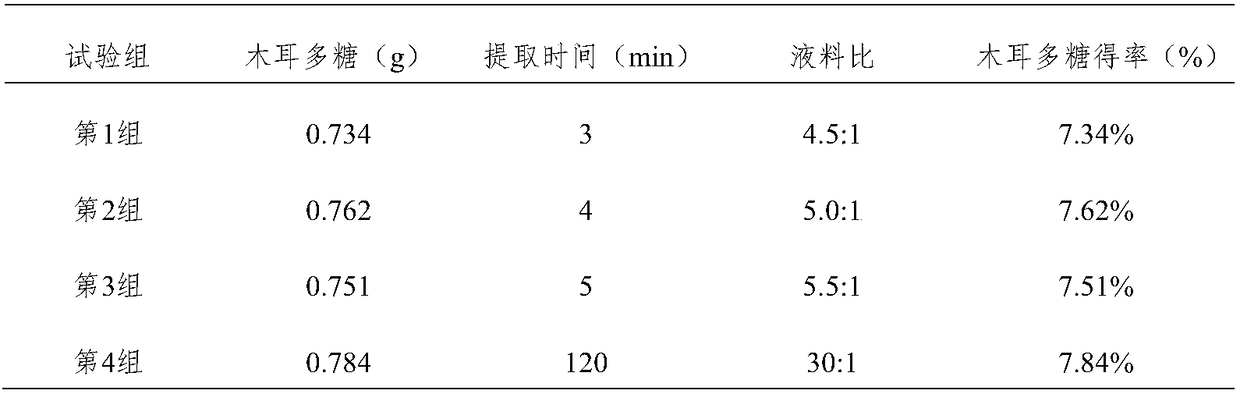

Examples

Embodiment 1

[0017] A method for extracting polysaccharides from fungus, the specific steps are:

[0018] Freeze-drying: freeze-dry 300 parts of fungus at -60℃ for 24 hours to obtain dry fungus;

[0019] Superfine grinding: Put the dry fungus into the airflow superfine grinding machine, using 8kg / m 2 Working pressure, superfine pulverization treatment under 10 conditions to obtain superfine fungus powder;

[0020] Enzymatic hydrolysis to break the wall: mix fungus superfine powder, sterile water, and cell wall enzyme at a mass ratio of 50:15:1, stir at 35℃ at a rate of 10r / min for 8h, and then at -60℃ , Freeze-drying for 24 hours to obtain a fungus freeze-dried powder; among them, the cell wall enzymes include pectinase, hemicellulase, and cellulase, and the mass ratio is 2:2:3.

[0021] Preparation of pre-extracted solution: Place 1500 parts of rose petals in a drying box, and dry them for 5 hours under the conditions of 0.5KPa and 45°C. After the gas is condensed, it becomes the rose cell liquid...

Embodiment 2

[0025] A method for extracting polysaccharides from fungus, the specific steps are:

[0026] Freeze-drying: freeze-dry 350 parts of fungus at -55°C for 24 hours to obtain dry fungus;

[0027] Superfine grinding: Put the dry fungus into the airflow superfine grinding machine, using 9kg / m 2 Working pressure, superfine pulverization treatment under 20Hz conditions to obtain superfine fungus powder;

[0028] Enzymatic hydrolysis and wall breaking: mix fungus superfine powder, sterile water, and cell wall enzyme at a mass ratio of 50:15:1, stir at a rate of 15r / min at 37°C for 9h, and then at -55°C , Freeze-drying for 24 hours to obtain agaric lyophilized powder; wherein the cell wall enzymes include pectinase, hemicellulase, and cellulase, and the mass ratio is 2:2:3.

[0029] Preparation of pre-extraction liquid: Place 1750 parts of rose petals in a drying box, and dry them for 6 hours under the conditions of 0.75KPa and 50°C. After the gas is condensed, it becomes the rose cell liquid; ...

Embodiment 3

[0033] A method for extracting polysaccharides from fungus, the specific steps are:

[0034] Freeze drying: freeze-dry 400 parts of fungus at -50°C for 24 hours to obtain dry fungus;

[0035] Superfine pulverization: put the dried fungus into the airflow superfine pulverizer, using 10kg / m 2 Working pressure, superfine pulverization treatment under 30Hz conditions to obtain superfine fungus powder;

[0036] Enzymatic hydrolysis and wall breaking: mix fungus superfine powder, sterile water, and cell wall enzyme at a mass ratio of 50:15:1, stir at 20r / min at 40℃ for 10h, and then at -50℃ , Freeze-drying for 24 hours to obtain agaric lyophilized powder; wherein the cell wall enzymes include pectinase, hemicellulase, and cellulase, and the mass ratio is 2:2:3.

[0037] Preparing the pre-extraction liquid: place 2000 parts of rose petals in a drying box, and dry them for 7 hours under the conditions of 1KPa and 55°C. After the gas is condensed, it becomes the rose cell liquid;

[0038] Micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com