High-activity flue gas desulfurization catalyst and preparation method thereof

A desulfurization catalyst and high-activity technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as strong interaction and uniform dispersion of unfavorable active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

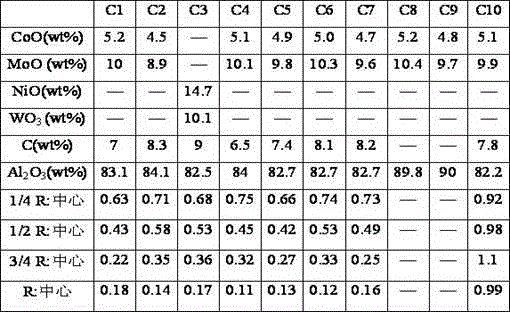

[0036] Weigh the pore volume as 0.9ml / g and the specific surface area as 220m 2 100 grams of gamma-phase cylindrical strip-shaped alumina carrier / g is put into the spray rolling pot, and in the rotating state, spray and impregnate 25 ml of xylitol aqueous solution with a mass concentration of 40% to the carrier in the rolling pot in the form of atomization ; Then continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution with a mass concentration of 20%; finally continue to spray and impregnate the alumina carrier with 40ml of xylitol aqueous solution with a mass concentration of 10%. After impregnation, transfer the alumina carrier into an autoclave, seal and heat-treat at 80°C for 120 minutes, then raise the temperature to 180°C, carbonize under autogenous pressure for 9 hours, and cool naturally to room temperature. Then the hydrothermally treated alumina carrier was dried at 120° C. for 3 hours.

[0037] The dried carrier is impregnated wit...

Embodiment 2

[0039] With embodiment 1, just use the aqueous solution of 30% sorbitol with 30ml mass concentration when spraying and impregnating for the first time, be the aqueous solution of 10% sorbitol with 50ml mass concentration when spraying and impregnating for the second time, spray for the third time When soaking, use 20ml of sorbitol aqueous solution with a mass concentration of 5%, the heat treatment temperature is 130°C, and the heat treatment time is 60 minutes. During the carbonization treatment, the temperature was 200° C., and the carbonization time was 8 hours.

[0040] The dried carrier is impregnated with an impregnation solution containing cobalt and molybdenum (cobalt nitrate and ammonium molybdate) for 3 hours, filtered off the excess solution, and dried at 120°C for 6 hours. The flue gas desulfurization catalyst C2 was obtained by calcination at lower temperature for 4 hours. The properties of the catalyst are shown in Table 1.

Embodiment 3

[0042] With embodiment 1, just adopt four times of spray impregnation, use 20ml mass concentration to be the aqueous solution of mannitol of 50% during the first spray impregnation, use 40ml mass concentration to be 30% sorbitol during the second spray impregnation 20ml aqueous solution of sorbitol with a mass concentration of 20% for the third spray dipping, and 20ml aqueous solution of sorbitol with a mass concentration of 10% for the fourth spray dipping, heat treatment temperature is 100°C, heat treatment The time is 90 minutes. During the carbonization treatment, the temperature was 240° C., and the carbonization time was 12 hours.

[0043] The dried carrier is impregnated with an impregnation solution containing nickel and tungsten (nickel nitrate and ammonium metatungstate) for 3 hours, filtered off the excess solution, and dried at 110°C for 8 hours. The flue gas desulfurization catalyst C3 was prepared by calcining at ℃ for 5 hours. The properties of the catalyst are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com