Purification method for beta-phenylethyl alcohol prepared by bio-fermentation

The technology of a biological fermentation method and a purification method is applied in the field of purification of β-phenethyl alcohol, and can solve the problems of a purification method without natural flavor β-phenethyl alcohol and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

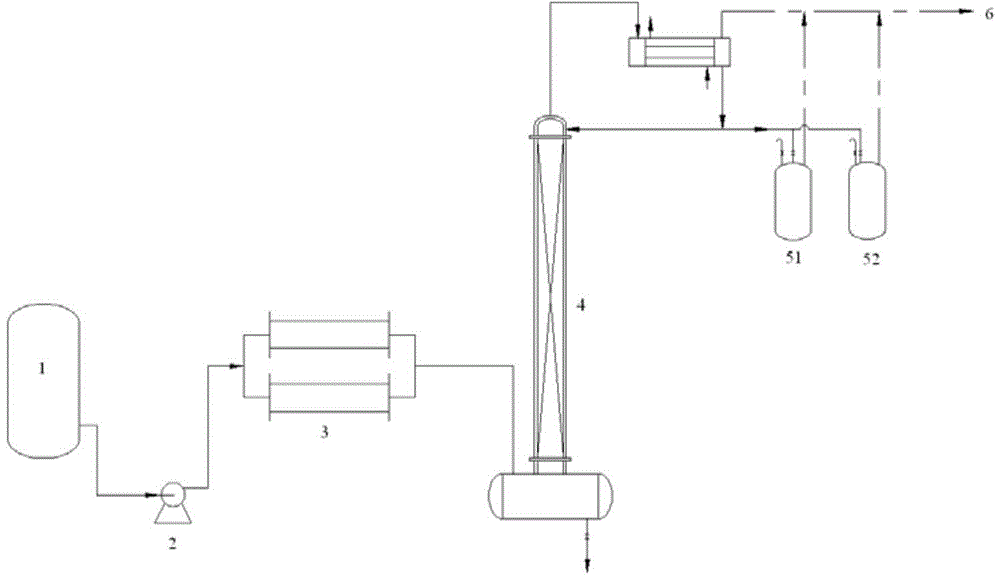

[0025] Such as figure 1 As shown, the crude product containing 85wt% β-phenylethanol prepared by the biological fermentation method is placed in the raw material tank 1, and is transported by the booster pump 2 and filtered through the ultrafiltration membrane module 3. Polysulfone membrane, feed liquid inlet pressure is 3×10 5 Pa, the outlet pressure is 0.6×10 5 Pa, collect permeate.

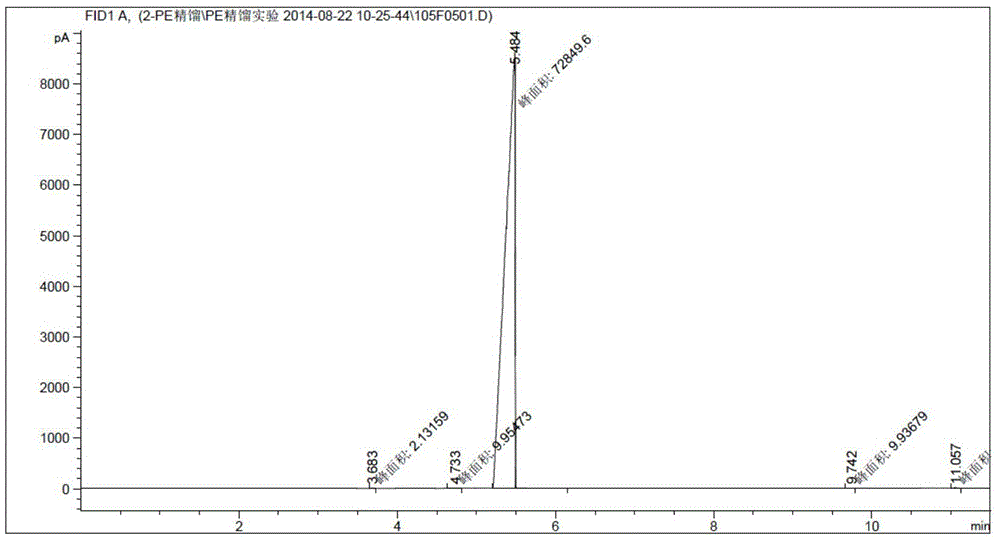

[0026] The permeate is added to the still of the rectification tower a4, and the intermittent rectification method is adopted. The entire operating system is connected to the vacuum system through the vacuum system pipe 6 to perform vacuum precision rectification. The rectification tower a4 is filled with high-efficiency wire mesh structured packing, the packing height is 5m, and the rectification tower a4 is operated under an absolute pressure of 10mmHg. In the rectifying process, at first with reflux ratio be 4: 1 to collect the low-boiling impurity of tower top, then collect the beta-phen...

Embodiment 2

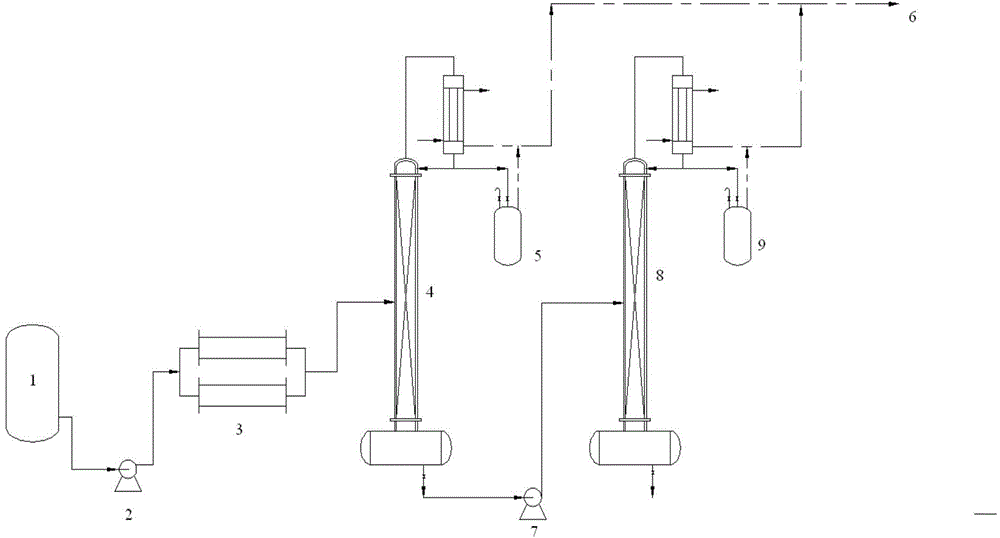

[0028] Such as image 3 As shown, the crude product containing 90wt% β-phenylethanol prepared by the biological fermentation method is uniformly placed in the raw material tank 1, and is transported into the ultrafiltration membrane module 3 by the booster pump 2 to filter, and the ultrafiltration membrane module 3 selects a molecular weight cut-off of 10KD ceramic membrane, feed liquid inlet pressure is 3×10 5 Pa, the outlet pressure is 0.3×10 5 Pa, collect permeate.

[0029] The permeate is added to the middle part of the rectification tower a4, and the whole operating system is connected to the vacuum system through the vacuum system pipe 6 to perform vacuum precision rectification operation. The rectification tower 4 is filled with high-efficiency random packing, the height of the packing is 2m, and the rectification tower a4 is operated under an absolute pressure of 5mmHg. during distillation. The top of the tower continuously collects low-boiling impurities with a re...

Embodiment 3

[0031] A method for purifying β-phenylethanol prepared by a biological fermentation method, comprising the following steps:

[0032] 1) Pretreatment of the crude product of β-phenylethanol: use the crude product of β-phenylethanol prepared by biological fermentation as raw material, remove residual macromolecular impurities in the β-phenylethanol through an ultrafiltration device, and collect the permeate; The ultrafiltration membrane used in the ultrafiltration device is a flat membrane with a molecular weight cut-off of 1000; the material of the ultrafiltration membrane is a polysulfone organic membrane material.

[0033] 2) Vacuum precision rectification purification: the permeate is added to a precision rectification tower, and the low-boiling point impurities and high-boiling point impurities are respectively removed through vacuum precision rectification to finally obtain a β-phenylethanol product with a purity higher than 99.9%.

[0034] The operating pressure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com