Secondary condensation extraction process and condensation equipment for rose essential oil

A technology of secondary condensation and rose essential oil, which is applied in the direction of essential oil/fragrance, steam condensation, fat production, etc. It can solve the problems of short condensation time, low condensation effect, and inability to fully analyze alcohol aromatic substances, so as to achieve quality improvement, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

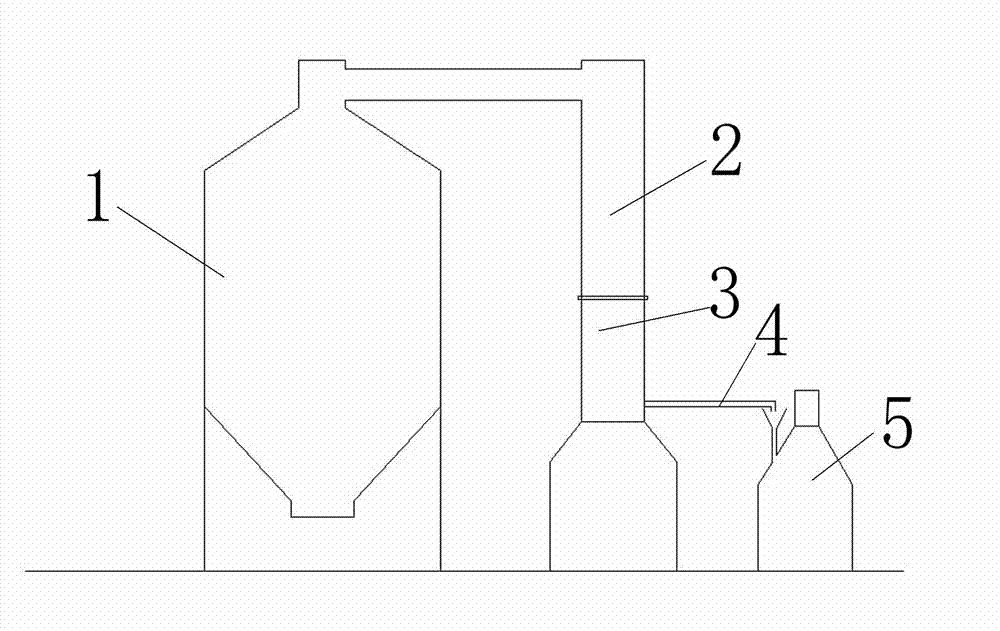

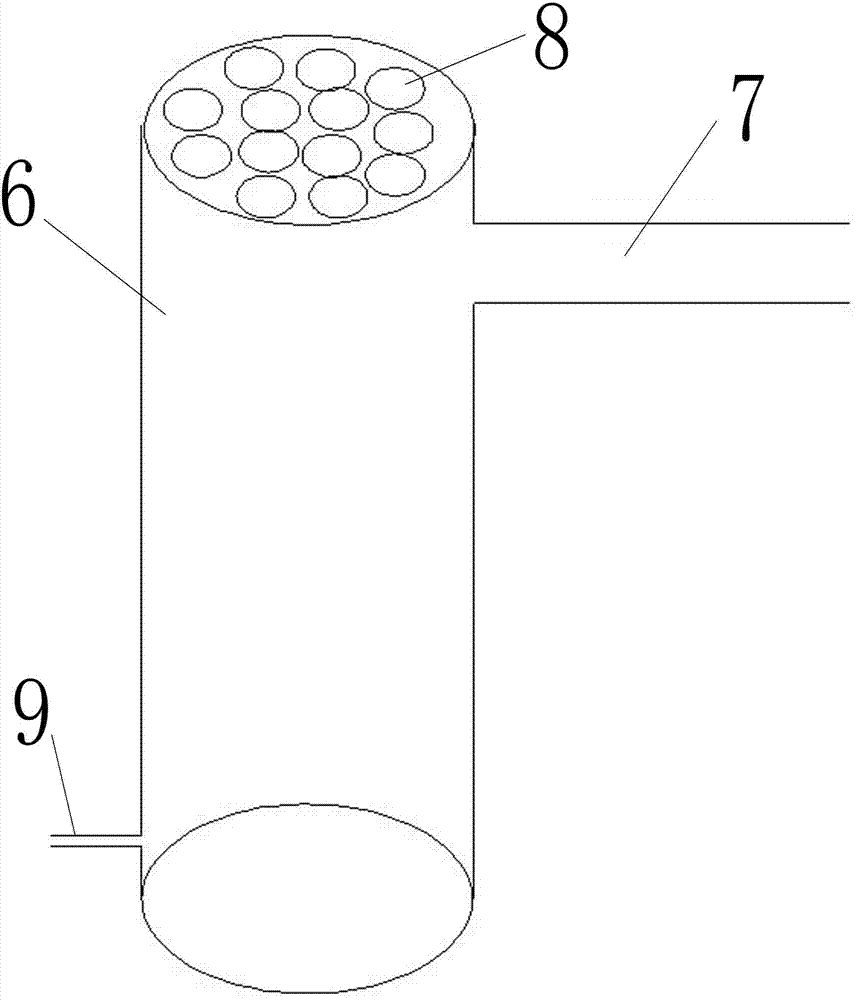

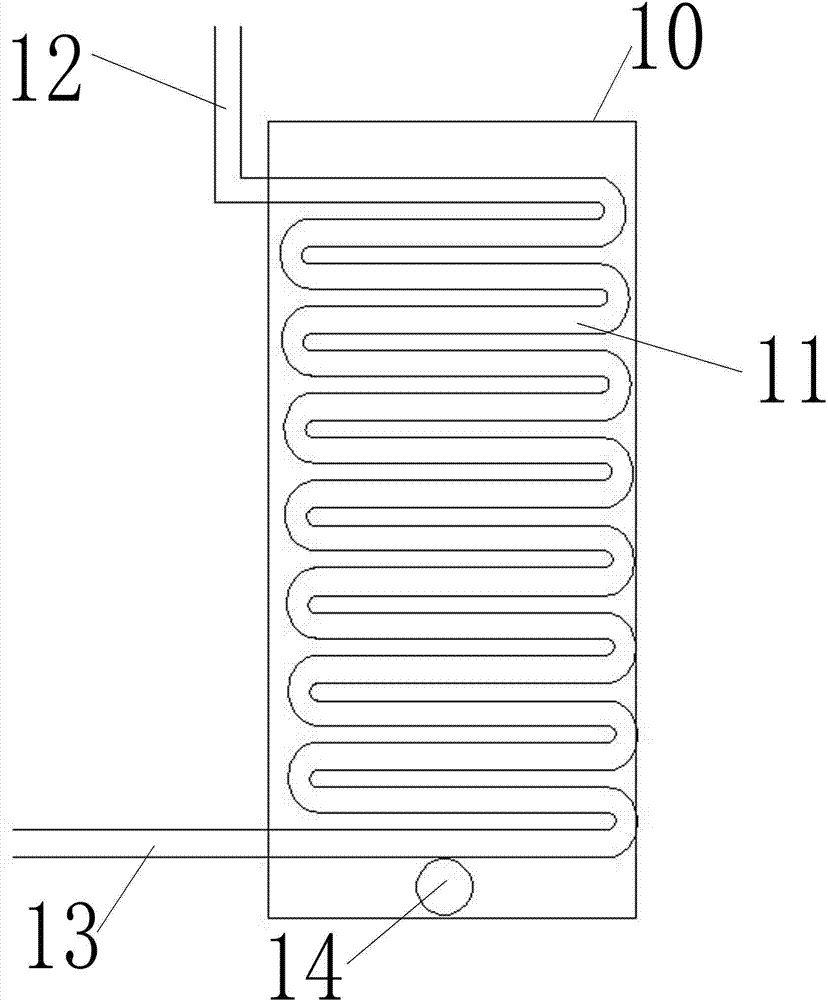

[0017] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0018] The secondary condensation extraction process of rose essential oil adopts the following steps successively:

[0019] (1) put the rose flowers into the distillation pot 1 for distillation to form oil-water mixed steam with a temperature of 95-100°C; (2) send the oil-water mixed steam into the inner cavity of the closed first-stage condenser 2, and the first-stage condenser The cold water pipe 8 in 2 is connected with cold water, and the oil-water mixer forms a distillate with a temperature of 55-70°C after exchanging heat with the cold water pipe 8; (3) Distillate with a temperature of 55-70°C formed in step (2) The effluent is transported to the secondary condenser 3 through the spiral tube 11 arranged in the secondary condenser 3, and cold water is passed into the secondary condenser 3, and the 55-70°C distillate in the spiral tube 11 After ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com