Energy-saving type dicumyl peroxide (DCP) device condensation reaction method

A technology of dicumyl peroxide and condensation reaction, which is applied to the preparation of peroxygen compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high energy consumption of devices, achieve low energy consumption, simple process, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

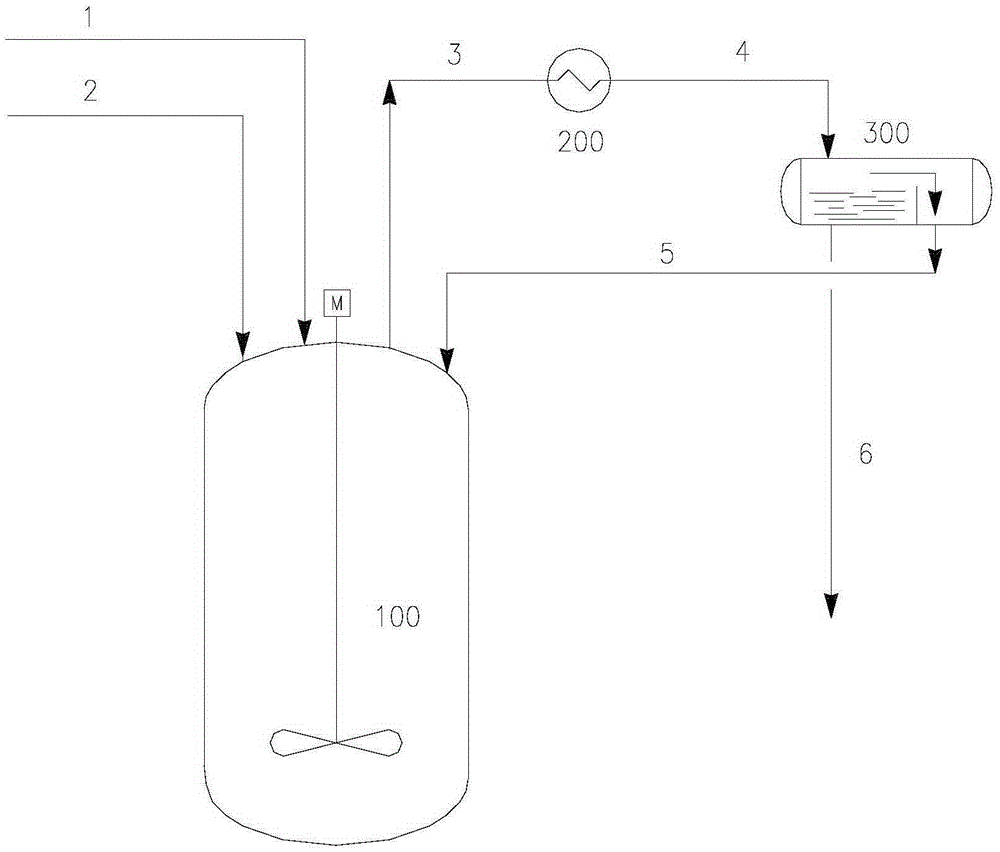

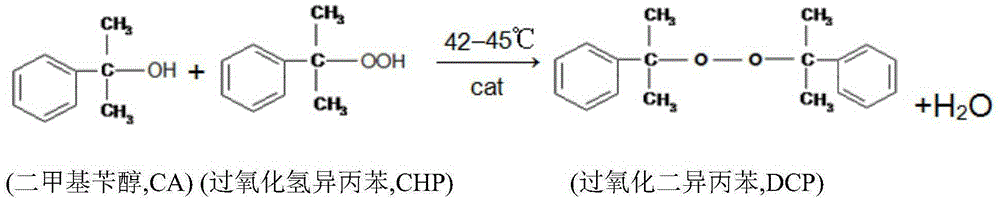

[0021] Adopt the method for condensation reaction of energy-saving type dicumyl peroxide DCP device of the present invention, the production scale of DCP industrial device is 200 tons / year. First add 0.22 tons of 100% hexanaphthene material (1) in condensation kettle (100), then add condensation after 0.023 tons / hour dimethyl benzyl alcohol and 0.052 tons / hour cumene hydroperoxide (2) meter Kettle (100), the operating temperature of the condensation reaction is 42°C, the operating pressure is 0.001MPaG, the condensation reaction heat is 21.3 kilowatts, absorbed by cyclohexane, cyclohexane itself vaporizes and enters together with the water vapor (3) generated by the reaction Condenser (200), the cooled and condensed material (4) enters the oil-water separator (300) for oil-water separation, the cyclohexane material (5) returns to the condensation kettle (100) for recycling, and the process water (6 ) is thrown out of bounds. Due to the adoption of the technical means of cyclo...

Embodiment 2

[0025] According to the conditions described in Example 1, only the production scale of the DCP industrial plant was changed to 1000 tons / year. Add 1.12 tons of 100% cyclohexane into the condensation kettle, then add 0.114 tons / hour of dimethyl benzyl alcohol and 0.259 tons / hour of cumene hydroperoxide to the condensation kettle, the operating temperature of the condensation reaction is 42 ° C, the operating pressure It is 0.001MPaG, and the condensation reaction exotherm is 106 kilowatts. Due to the adoption of the technical means of cyclohexane vaporization and absorption of reaction heat of the present invention, the method of nitrogen bubbling is avoided, and the energy consumption of the DCP unit is reduced by 212.4 tons of standard oil per year.

Embodiment 3

[0029] According to the conditions described in Example 1, only the production scale of the DCP industrial plant was changed to 20,000 tons / year. Add 22.3 tons of 100% cyclohexane to the condensation kettle, then add 2.27 tons / hour of dimethyl benzyl alcohol and 5.18 tons / hour of cumene hydroperoxide to the condensation kettle, the operating temperature of the condensation reaction is 42 °C, and the operating pressure It is 0.001MPaG, and the condensation reaction exotherm is 2127 kilowatts. Due to the adoption of the technical means of cyclohexane vaporization and absorption of reaction heat of the present invention, the method of nitrogen bubbling is avoided, and the energy consumption of the DCP unit is reduced by 4248 tons of standard oil per year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com