High-temperature-resistant low-shrinkage impact-resistant PVC cable material for 5G optical cables

A low-shrinkage, impact-resistant technology, applied in the field of environmentally friendly cable materials, can solve the problems of low extrusion efficiency of PVC cable materials, poor product appearance brightness, and high product material costs, so as to change the brightness, change the lubrication effect, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

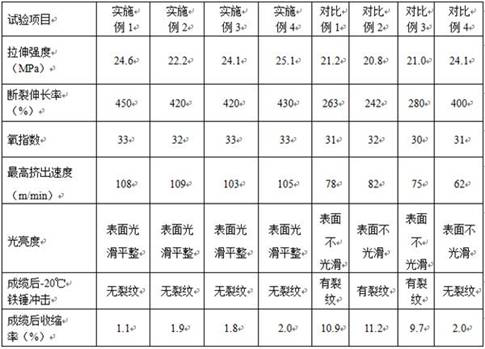

Examples

Embodiment 1

[0031] Embodiments 1 to 4: A PVC cable material for high-temperature-resistant, low-shrinkage, and impact-resistant 5G optical cables, consisting of the following components by weight, as shown: The filler in embodiment 1 is a mixture of calcium carbonate and talcum powder. The filler of 2 is talcum powder, the filler of embodiment 3 is kaolin, and the filler of embodiment 4 is the mixture of talcum powder, kaolin;

[0032] The ABS of embodiment 1 is PA-747R, the ABS of embodiment 2 is PA-747F, the ABS of embodiment 3 and embodiment 4 is the mixture of PA-747R and PA-747F;

[0033] The glass microspheres of embodiment 1 and embodiment 2 are ZK-1W, and the glass microspheres of embodiment 3 and embodiment 4 are the mixture of PA-747R and PA-747F;

[0034] The nitrile rubber of embodiment 1 and embodiment 2 is P83, and the nitrile rubber of embodiment 3 and embodiment 4 is P830;

[0035] The preparation method of the above-mentioned PVC cable material for high-temperature-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com