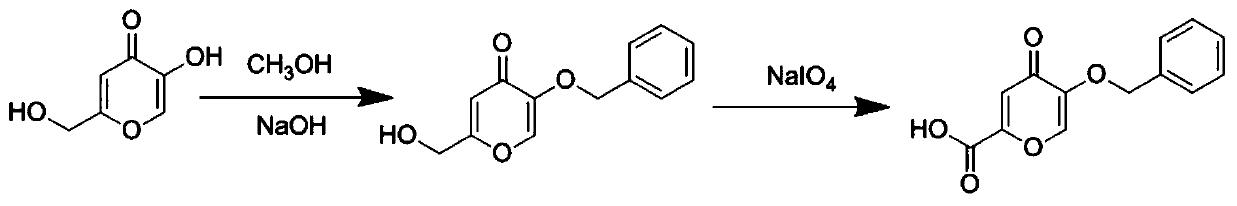

A kind of preparation method of 5-benzyloxy-4-oxo-4h-pyran-2-carboxylic acid

A technology of benzyloxy and oxo, which is applied in the field of preparation of 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid, which can solve the problems of high waste water content, low product purity, and the cost of separated products High-level problems, to achieve the effect of easy separation and cost-saving separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid, first 90g of kojic acid is added to a 2000ml single-necked flask, then 660ml of methanol is added to dissolve the kojic acid, and then The 40% alkali solution of 80g benzyl chloride and 63ml, heat up and reflux reaction 16 hours to obtain reaction solution; Reaction solution is carried out decompression distillation, just stops distillation until solvent is evaporated to dryness, then cools to normal temperature; Add 60ml methyl alcohol and 180ml water in the substance, stir, wash, filter, the solid obtained is dried, and the solid that obtains 103g light yellow is intermediate; 103g intermediate is joined in the reactor, then adds 2000ml water, will Lower the temperature to 0°C, add sodium periodate, control the temperature at not higher than 5°C, add 40ml of water dropwise after the addition, stir for 5 minutes, then raise the temperature to 12°C, stir for 2.5 hours to obtain the reaction solution; ...

Embodiment 2

[0021] A preparation method of 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid, first 90g of kojic acid is added to a 2000ml single-necked flask, then 660ml of methanol is added to dissolve the kojic acid, and then The 40% alkali solution of 88g benzyl chloride and 63ml, heats up and refluxes and reacts for 17 hours to obtain reaction solution; Reaction solution is carried out vacuum distillation, just stops distillation until solvent is evaporated to dryness, then cools to normal temperature; Add 60ml methyl alcohol and 240ml water in the substance, stir, wash, filter, the solid obtained is dried, and the solid that obtains 116g light yellow is intermediate; 116g intermediate is joined in the reactor, then adds 2000ml water, will Lower the temperature to -5°C, add sodium periodate, and control the temperature at no higher than 5°C. After the addition, add 40ml of water dropwise, stir for 10 minutes, then raise the temperature to 17°C, and stir for 3 hours to obtain a reaction sol...

Embodiment 3

[0023] A preparation method of 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid, first 90g of kojic acid is added to a 2000ml single-necked flask, then 660ml of methanol is added to dissolve the kojic acid, and then The 40% alkali solution of 96g benzyl chloride and 63ml, heat up and reflux reaction to obtain reaction solution for 18 hours; The reaction solution is subjected to vacuum distillation, until the solvent is evaporated to dryness and just stop distillation, then cooled to normal temperature; Add 60ml methyl alcohol and 300ml water in the substance, stir, wash, filter, the solid that obtains is dried, and the solid that obtains 116g light yellow is intermediate; 116g intermediate is joined in the reactor, then adds 2000ml water, will Lower the temperature to -10°C, add sodium periodate, and control the temperature at no higher than 5°C. After the addition, add 40ml of water dropwise, stir for 15 minutes, then raise the temperature to 22°C, and stir for 3.5 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com