Bidirectional magnetic projection automatic separation device for plastic waste

A separation device and waste technology, which are applied in the field of automatic separation devices of plastic waste bidirectional magnetic projection, can solve the problems of inability to meet the need for separation of large quantities of plastic waste, decrease in separation accuracy, and small amount of single separation, and achieve an increase in the Separation cost, efficiency reduction, effect of separation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

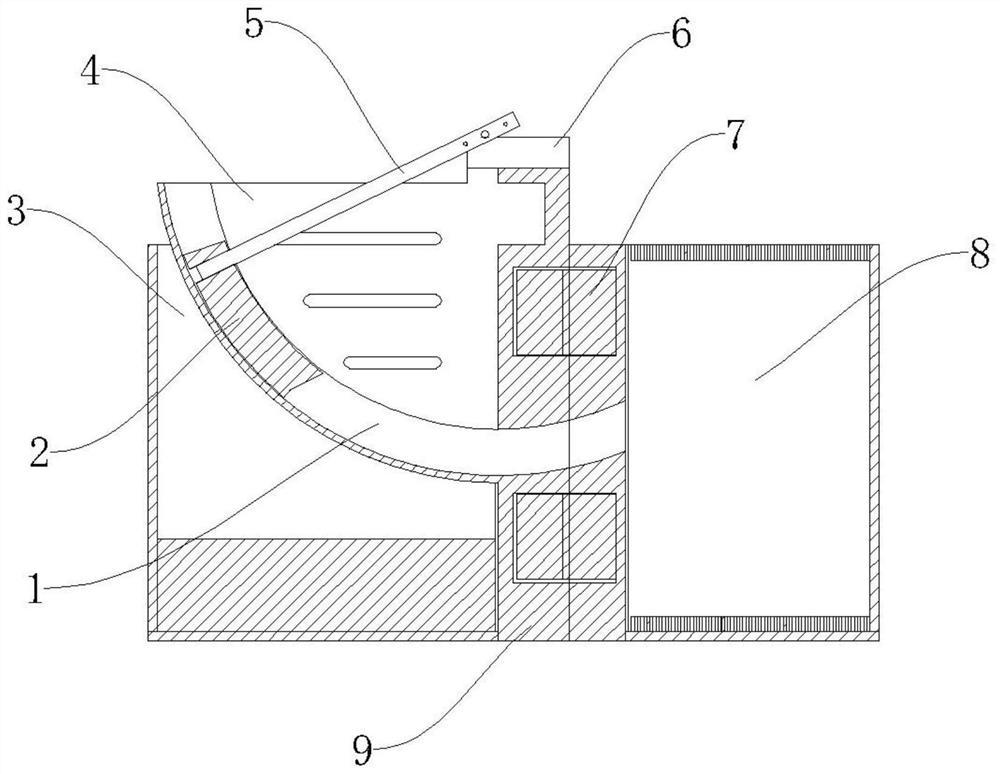

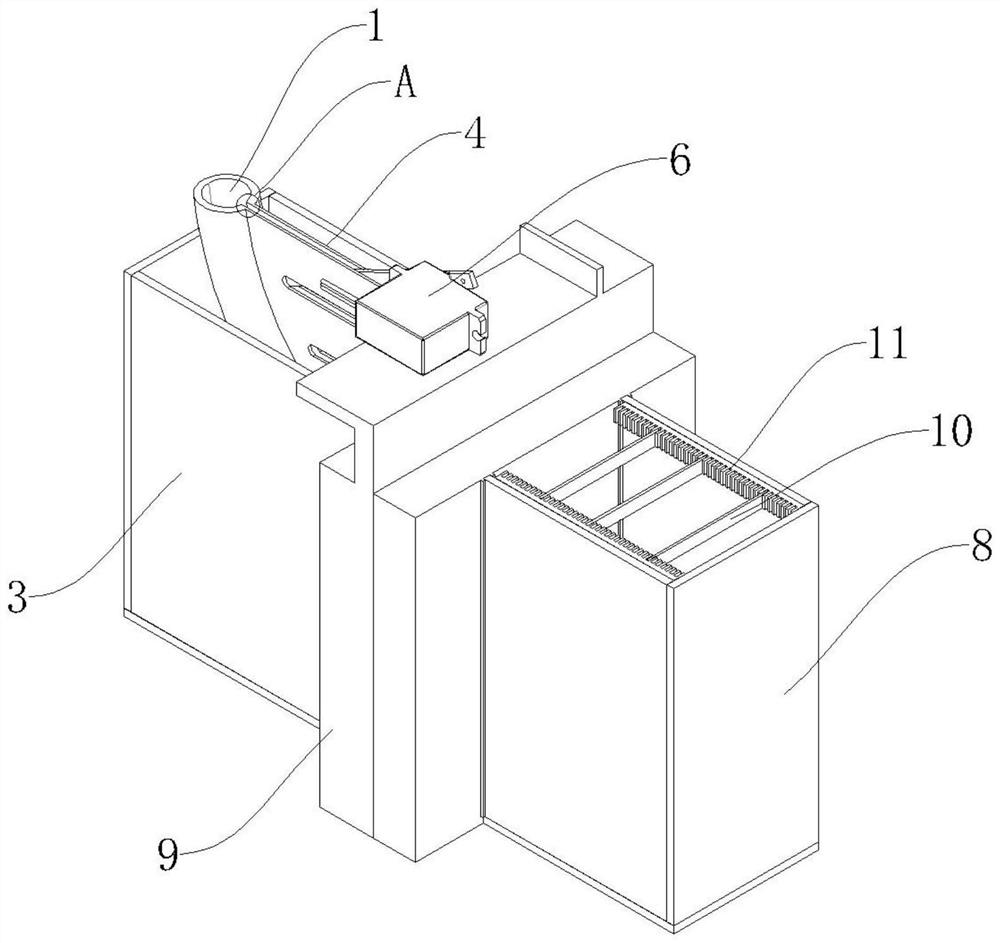

[0066] Such as Figure 1~5 As shown, the plastic waste two-way magnetic projection automatic separation device proposed by the present invention includes a feeding mechanism, a separation box and two ring magnets that are both axially magnetized;

[0067] The feeding mechanism includes a feeding box 3, a feeding channel 1 and a pendulum 2; two ring magnets 7 are arranged coaxially, and their central axes are arranged horizontally, and are installed on the feeding box 3 and the separation box 8 through two detachable cover plates 9 Between; separation box 8 is equipped with paramagnetic medium solution.

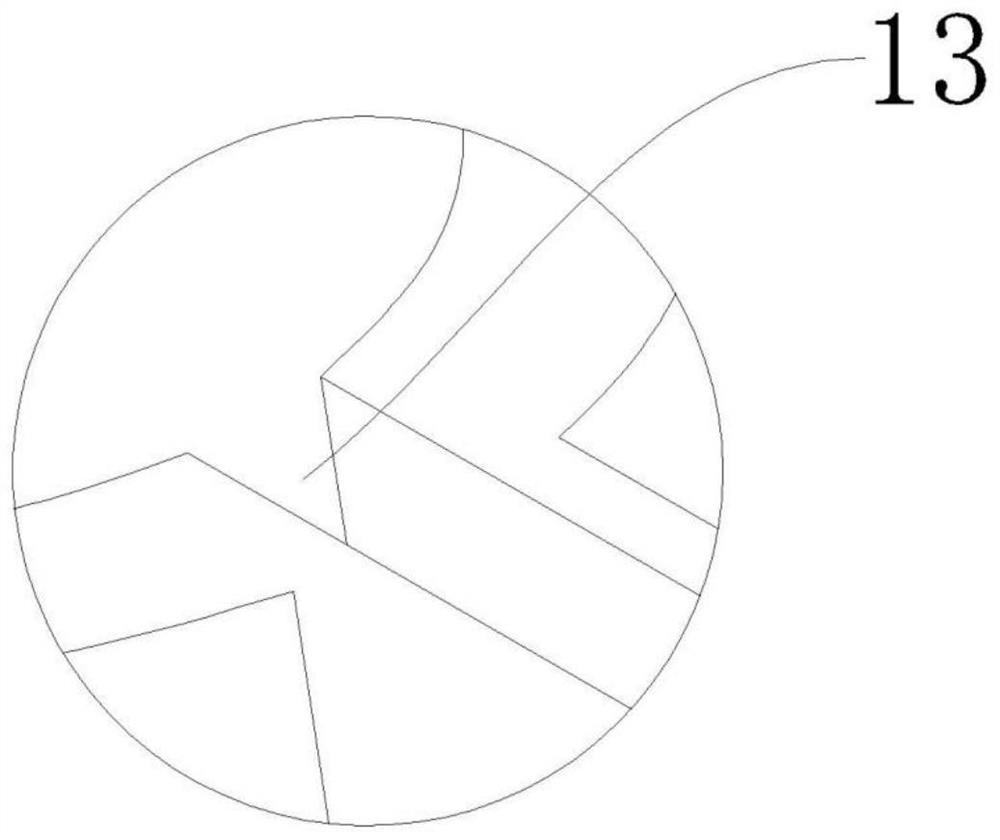

[0068] The feed channel 1 includes a feed section and a discharge section, and the discharge section communicates with a separation box 8 . The opposite sides of the two cover plates 9 are respectively provided with annular placement grooves 12 , and the ring magnets 7 are installed in the annular placement grooves 12 . A cylindrical protrusion is formed in the middle of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com