Patents

Literature

31results about How to "Increased separation cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

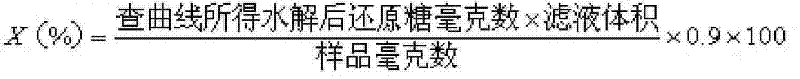

Comprehensive utilization method of corn cob

ActiveCN101628920AEasy to separatePromote conversionBiofuelsLignin derivativesSocial benefitsState of art

The invention provides a comprehensive utilization method of corn cob, which effectively separates hemicellulose, lignin and cellulose contained in a reproducible biological resource of corn cob in a reasonable process order at low cost and high efficiency, and makes full use of every type of biomass components, thereby solving the problem of utilization of residue in the biomass refining process of preparing ethanol and butanol by extracting xyio-oligosacchandes and enzymolysis from the corn cob in the prior art, and making reasonable and effective use of main components of biomass contained in the corn cob; particularly, the lignin can substitute partial petrochemical materials to prepare modified high-molecular materials, thereby reducing the cost of high-molecular materials and saving the energy consumption of petrochemical materials to bring great social benefit; in addition, the comprehensive utilization method of corn cob is featured by simple processing technique, easy implementation and favorable effect.

Owner:重庆辉泰化工销售有限公司

Method for preparing D-mannose

InactiveCN102329340AReduce inhibitionGuaranteed conversion rateSugar derivativesSugar derivatives preparationOrganic solventFiltration

The invention discloses a method for preparing D-mannose. The method comprises the following steps of: epimerizing glucose to partially transform the glucose into mannose to obtain a mixed solution of the glucose and the mannose, separating the mixed solution for three times by a simulated moving bed to obtain C1 which is rich in a mannose component as well as A2, B2 and C2 which are rich in a glucose component, and desalting the C1, concentrating, crystallizing, centrifuging and drying to obtain high-purity D-mannose. The separated liquid which is obtained through first-time separation by the simulated moving bed and is rich in the glucose component is filtered by a membrane filtration device, then dialysate is epimerized, and the separated liquid B2 and the separated liquid C2 which are obtained through second-time separation and third-time separation by the simulated moving bed enter the simulated moving bed and are separated for the first time again. In the process, a membrane separation technology and a high-efficiency separation effect of the simulated moving bed are utilized, and a crystal product with the purity of over 99 percent is directly obtained in a way of the combination of cooling crystallization and organic solvent crystallization through one-step crystallization without a refinement link; and the process is simple and the product can be produced easily.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Method for separating and extracting squalene in mixed tocopherols

ActiveCN103288571AGuaranteed purityGuaranteed RecoveryAdsorption purification/separationAlcoholElution

The invention provides a method for separating and extracting squalene in mixed tocopherols. The method comprises steps of: filling silochrom with the meshes of 100-200 into a chromatographic column, adopting an elution solvent to elute and compact the silochrom, then feeding the tocopherols into the chromatographic column according to a proper ratio, and separating the squalene from natural vitamin E through utilizing column chromatography. By adopting the separating and extracting method, the technological process is simple, the purity and recovery rate of the squalene can be improved to the maximum extent through utilizing a gradient elution method, silicagel columns can be well regenerated through utilizing strong polar solvents such as methyl alcohol and the like, and the method has the advantages of large solvent usage, easiness in recycling, small consumption and small environmental pollution.

Owner:NINGBO DAHONGYING BIO ENG

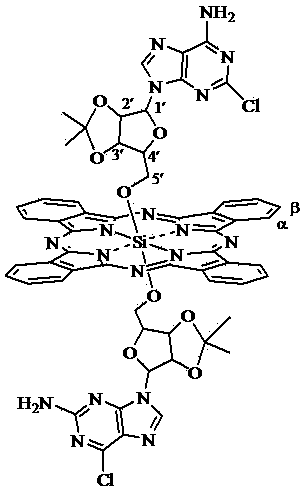

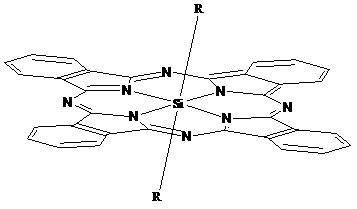

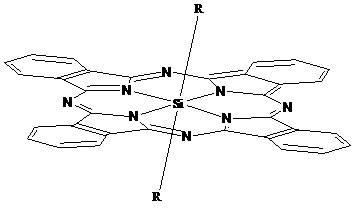

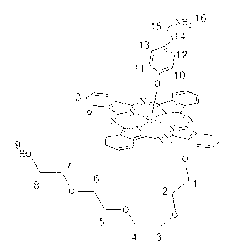

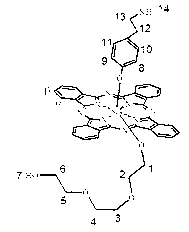

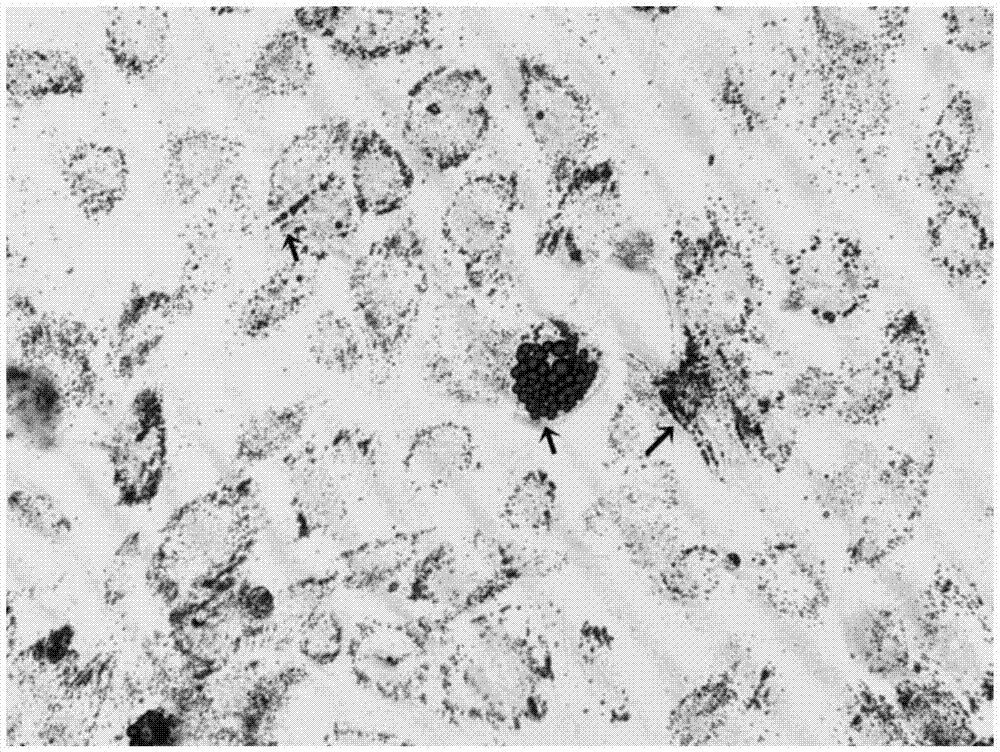

Axial nucleoside asymmetrically-modified silicon phthalocyanine and preparation method and application thereof

ActiveCN103435639AGood amphipathyGood biocompatibilityAntibacterial agentsGroup 4/14 element organic compoundsPhotosensSilicon phthalocyanine

The invention discloses axial nucleoside asymmetrically-modified silicon phthalocyanine and a preparation method and application thereof, belonging to the preparation field of a photodynamic medicine or a photosensitizer. The axial nucleoside asymmetrically-modified silicon phthalocyanine disclosed by the invention can be applied to photodynamic treatment, photodynamic diagnosis or photodynamic disinfection as a photosensitizer, has the structural characteristic of axial asymmetric substitution, and shows good amphipathicity and excellent photodynamic activity.

Owner:FUZHOU UNIV

Catalyst for preparing 1,3,3,3-tetrafluorohydrazine propylene from 1,1,1,3,3-perfluoropropane

ActiveCN106902849AIncrease costLow costPreparation by hydrogen halide split-offPhysical/chemical process catalystsMole ratioTetrafluorohydrazine

The invention discloses a catalyst for preparing 1,3,3,3-tetrafluorohydrazine propylene from 1,1,1,3,3-perfluoropropane. The composition is MxOy / AlF3, wherein a carrier AlF3 is an active carrier which is of an alpha phase structure, has the specific surface area greater than 150 m<2>.g<-1> and has the aperture distribution concentrated at 15 to 40 nm; MxOy is one of MgO, Fe2O3, Co2O3 or CuO; the mole ratio of MxOy to AlF4 is 1: (5 to 50). A preparation method of the catalyst comprises the following steps: carrying soluble salt of any element of Mg, Fe, Co or Cu through active alpha-phase AlF3 which has a large specific surface area and a mesoporous structure and serves as the carrier via an equivalent immersion method, and preparing the catalyst through drying and high temperature roasting. The catalyst disclosed by the invention is excellent in performance; in a preparation process, no expensive noble metal compounds are needed, the cost is low, and the activity is high; during reaction at 280 DEG C, the conversion ratio of the 1,1,1,3,3-perfluoropropane is 70 percent or above, and the catalyst is long in service life and can stably work for 360 hours; meanwhile, no diluting gas is fed in the reaction process, and the catalyst has industrial application value.

Owner:XIAN MODERN CHEM RES INST

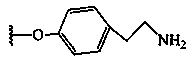

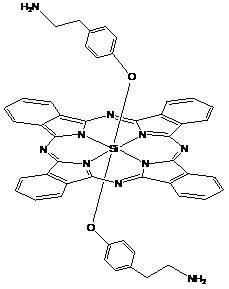

Phthalocyanine silicon modified by amino ethyl groups and phenoxy groups as well as preparation method and application thereof

ActiveCN102659793AEasy to manufactureFast productionAntibacterial agentsSenses disorderPhotosensPharmaceutical drug

The invention discloses phthalocyanine silicon modified by amino ethyl groups and phenoxy groups as well as a preparation method and application thereof, which belong to the field of the preparation of photodynamic medicines or photosensitizers. The phthalocyanine silicon modified by the amino ethyl groups and the phenoxy groups, which is provided by the invention, can be used as a photosensitizer for photodynamic therapy, photodynamic diagnosis or photodynamic disinfection, has the advantages of definite composition, simple and convenient preparation, high photodynamic activity and the like, is easy to realize industrialization and has obvious economic and social benefits.

Owner:FUZHOU UNIV

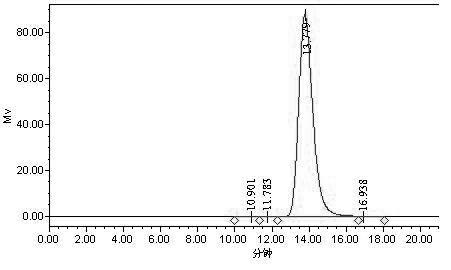

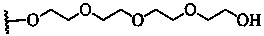

Silicon phthalocyanine axially modified by aminoethyl phenoxyl and polyethylene glycol oligomer

ActiveCN103254223AGood amphipathyAsymmetric instead of uniqueAntibacterial agentsBiocidePhotosensOligomer

The invention discloses silicon phthalocyanine axially modified by aminoethyl phenoxyl and polyethylene glycol oligomer as well as a preparation method and application of silicon phthalocyanine, belonging to the field of preparation of photodynamic medicaments or photosensitizers. The silicon phthalocyanine provided by the invention can be used as a photosensitizer for photodynamic treatment, photodynamic diagnosis or photodynamic sterilization, has the structural characteristic of axially asymmetrical substitution and shows favorable amphipathy and extremely high photodynamic activity.

Owner:FUZHOU UNIV

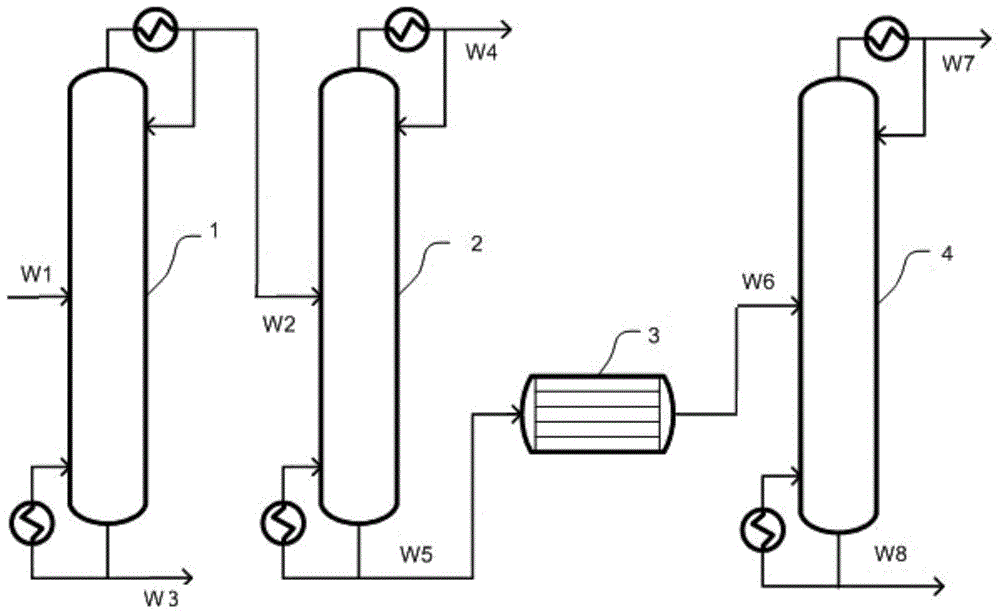

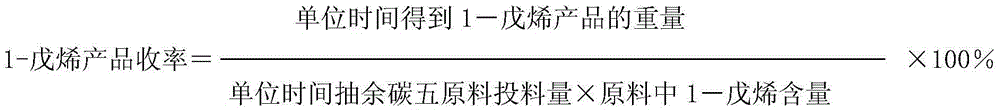

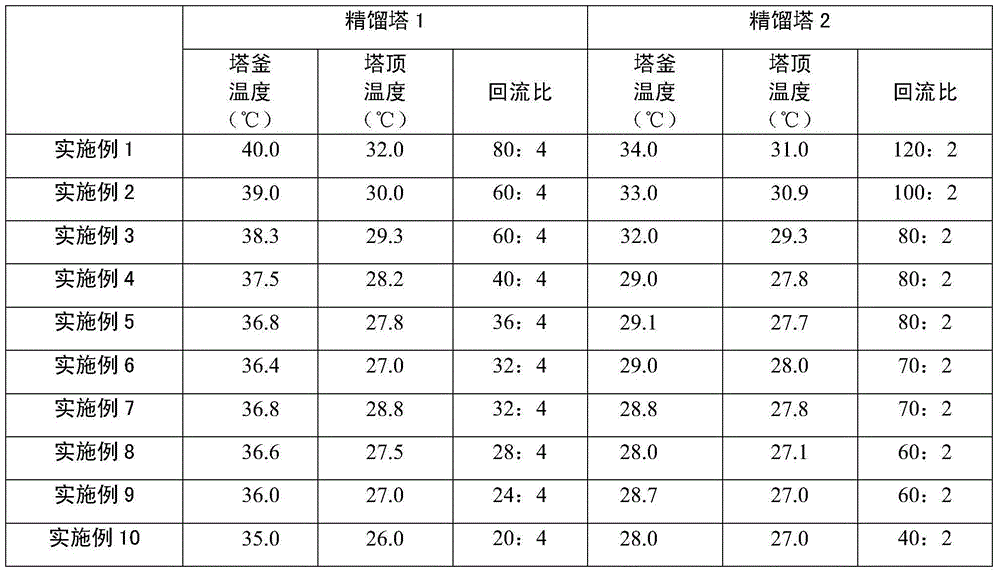

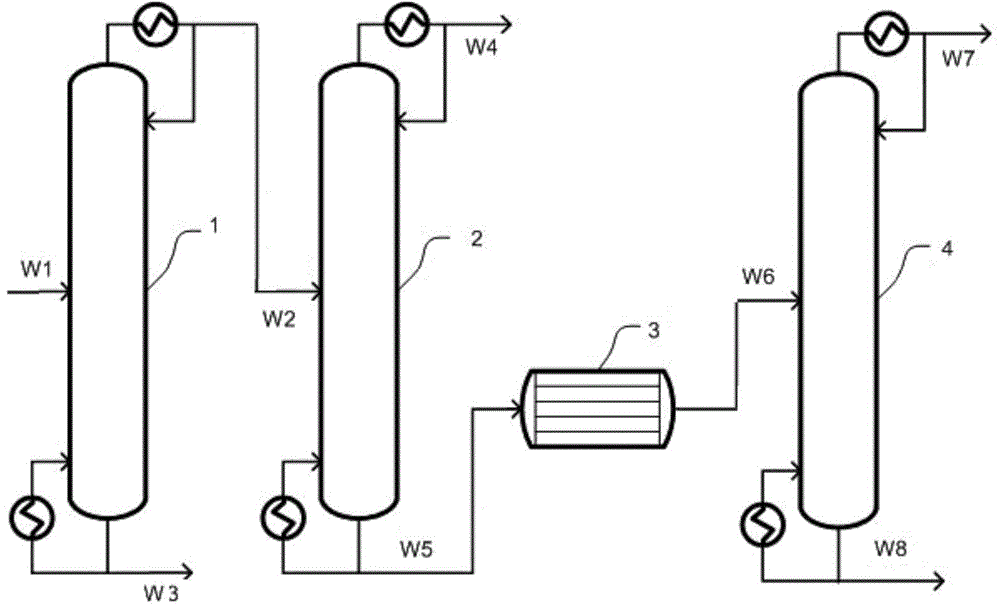

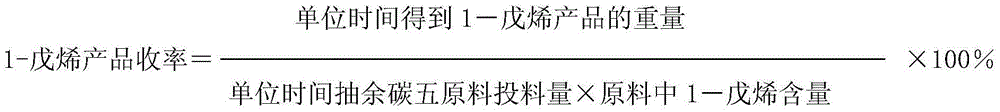

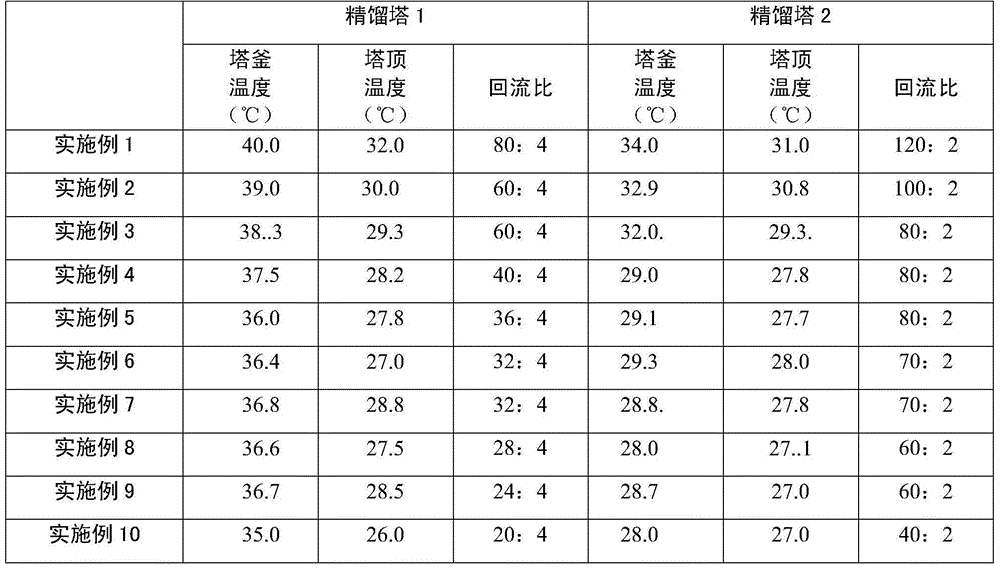

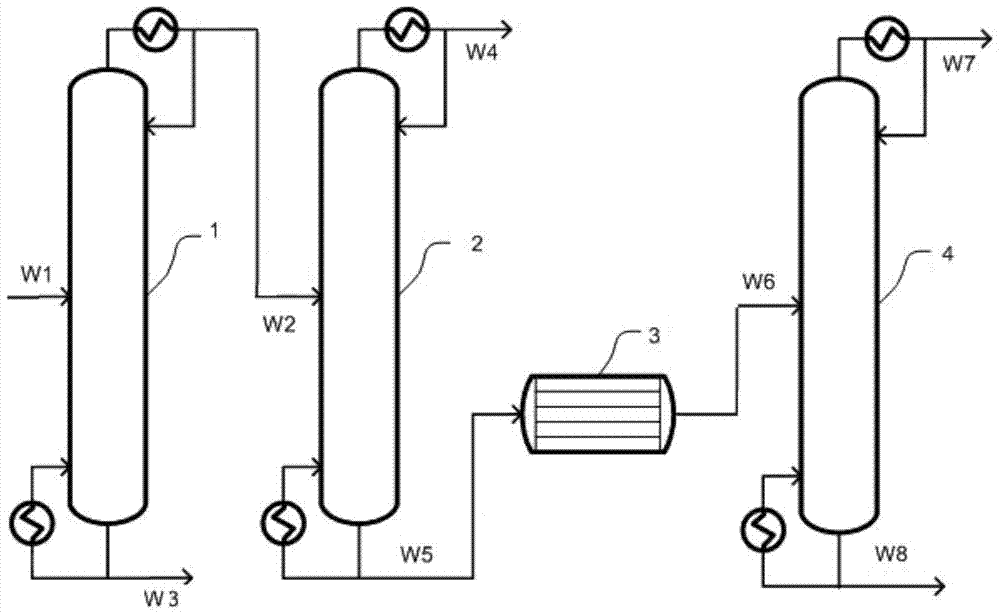

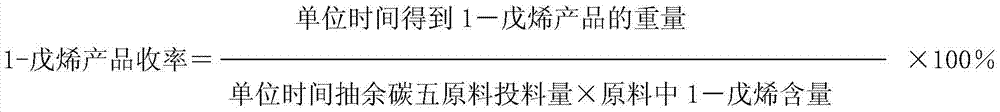

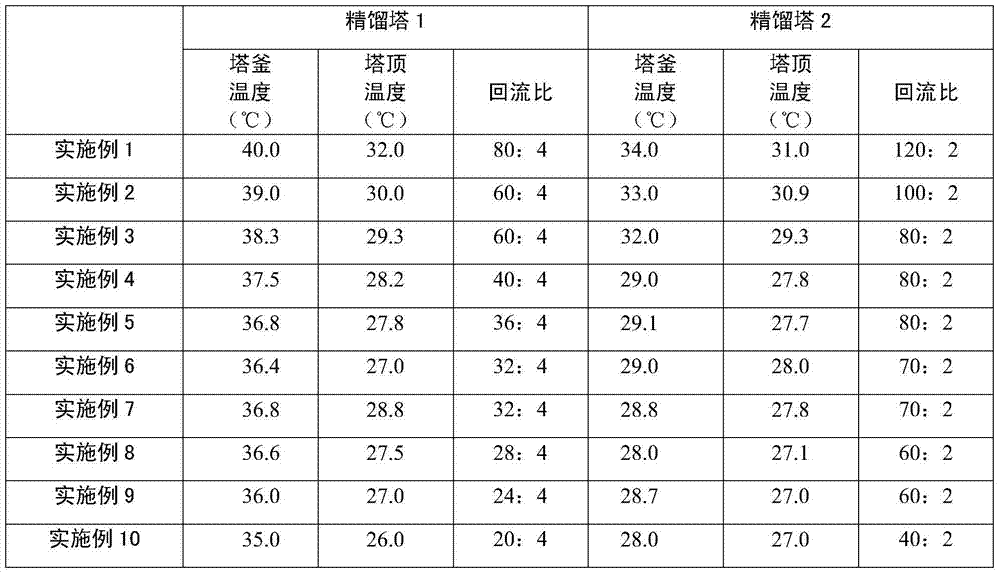

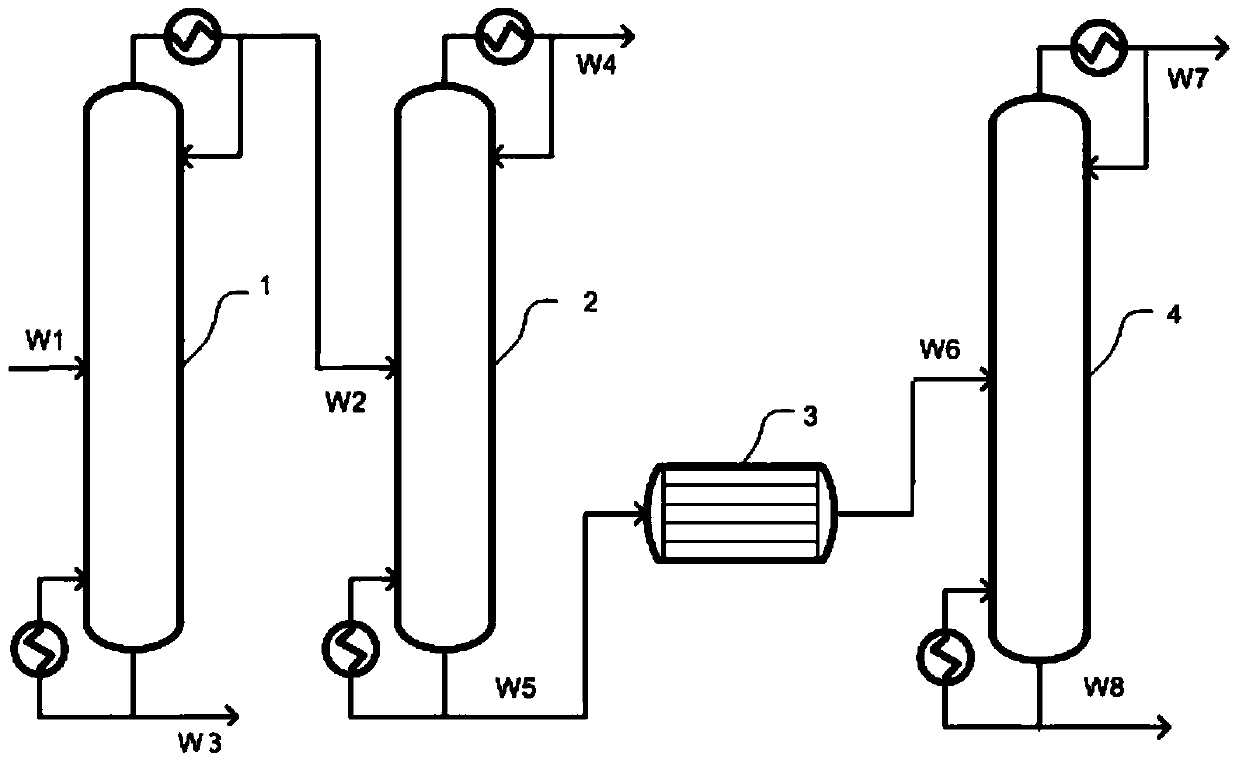

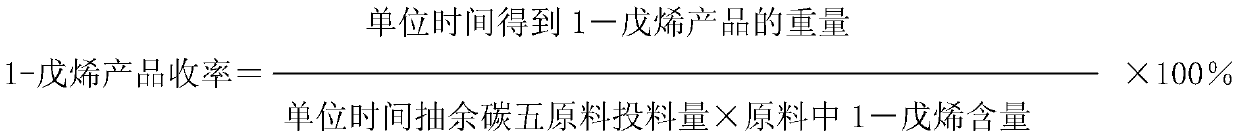

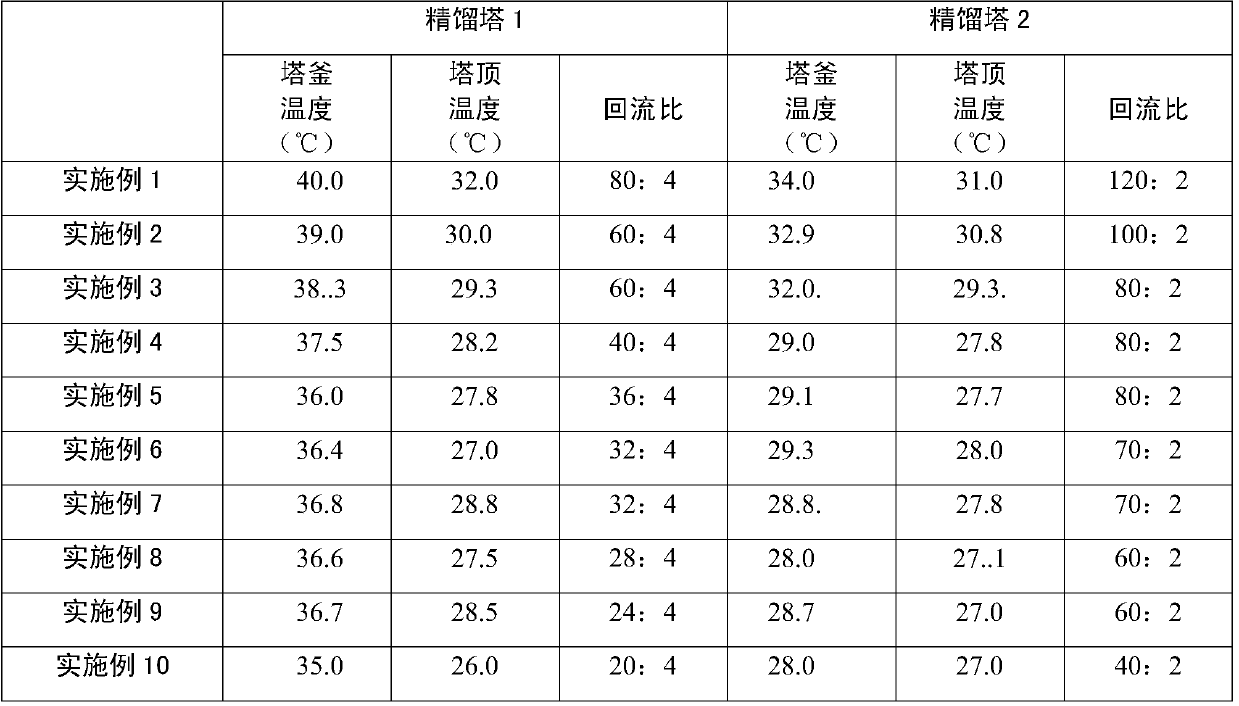

A method of preparing high-purity 1-pentene

ActiveCN104557410AAdd recovery unitIncreased separation costDistillation purification/separationChemical modification purification/separationAlkaneTower

A method of preparing high-purity 1-pentene is disclosed. The method includes steps of: 1) rectifying a raw material that is raffinate C5 after extraction and separation of diolefine and isopentene so as to separate and remove heavy components, obtaining an enriched 1-pentene fraction from the tower top, and discharging heavy components from the tower bottom; 2) subjecting the enriched 1-pentene fraction obtained from the tower top in the step 1) to precision rectification so as to remove light components, obtaining C5 alkanes and other light components from the tower top, and obtaining a 1-pentene crude product from the tower bottom; 3) subjecting the 1-pentene crude product obtained in the step 2) and methanol to esterification to remove 2-methyl-1-butene that is difficult to separate from the crude product; and 4) feeding esterification products obtained in the step 3) to a rectification tower, and purifying to obtain the 1-pentene having purity higher than 98%. By improving process steps, the method simplifies the process, reduces the production cost, and improves the economical efficiency of the process of preparing the high-purity 1-pentene.

Owner:CHINA PETROLEUM & CHEM CORP +1

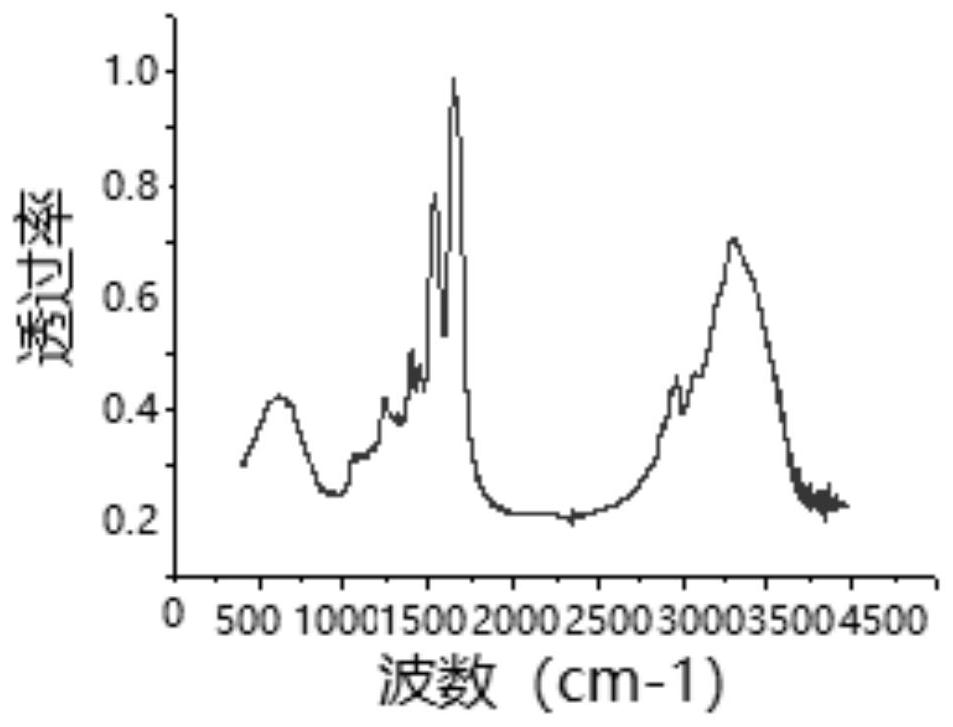

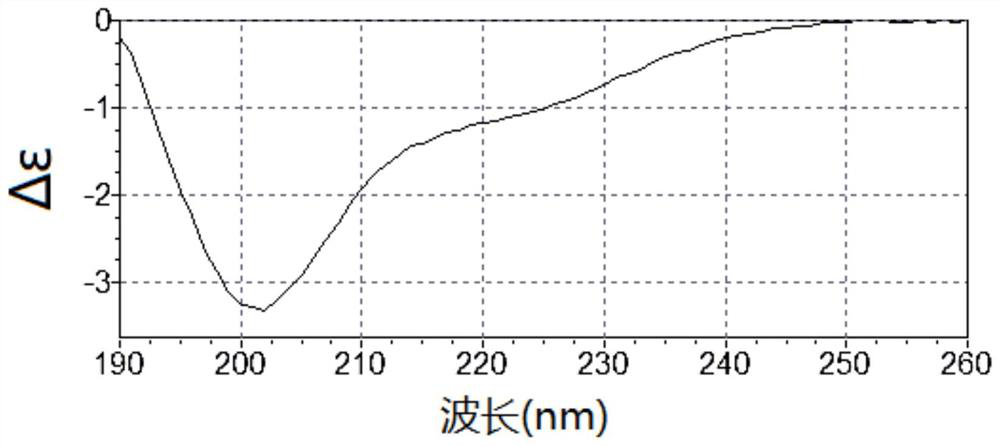

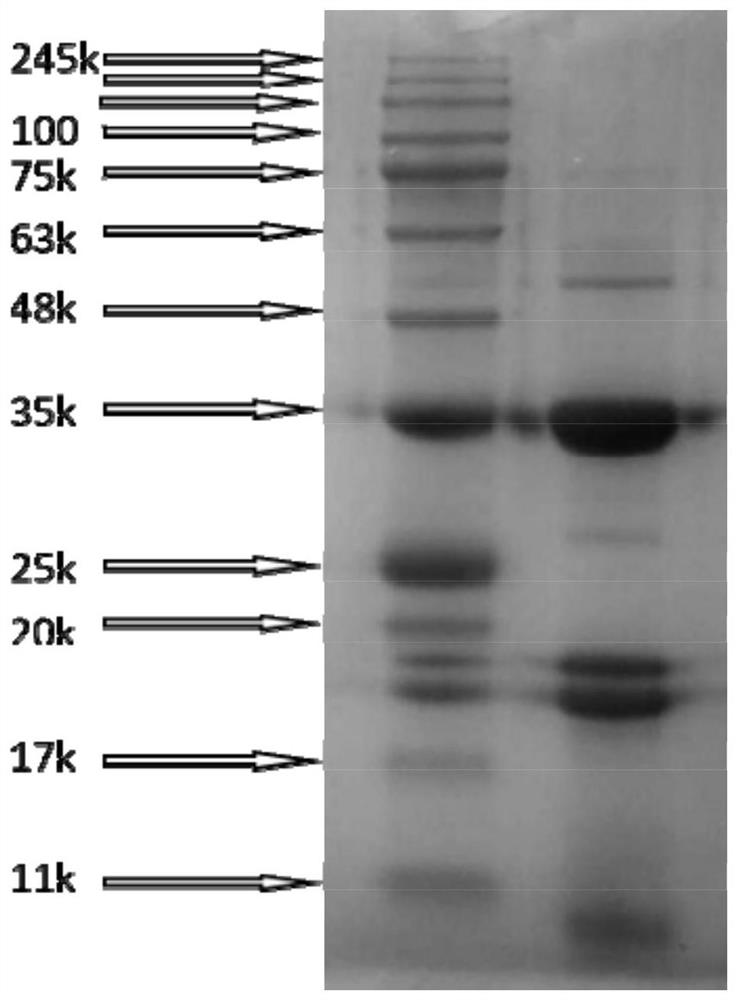

Extraction method of fructus cannabis globulin, product and application thereof

ActiveCN111978385AHigh yieldHigh purityHydrolysed protein ingredientsAntinoxious agentsBiotechnologyCannabis

The invention relates to an extraction method of fructus cannabis globulin, a product and application thereof. The extraction method comprises the following steps: dehydrating and deoiling fructus cannabis, mixing with a salt solution, extracting, filtering and cooling to obtain the fructus cannabis globulin. The extraction method provided by the invention is simple and easy to operate, the extracted globulin is high in yield and high in purity, contains all essential amino acids of a human body, is particularly high in arginine content, can be applied to foods, health products or medicines, and has the effects of resisting fatigue, improving immune health, preventing cardiovascular diseases and the like.

Owner:YUNNAN HEMPMON PHARMA CO LTD

Heavy metal removal preparation, and synthesis method and application thereof

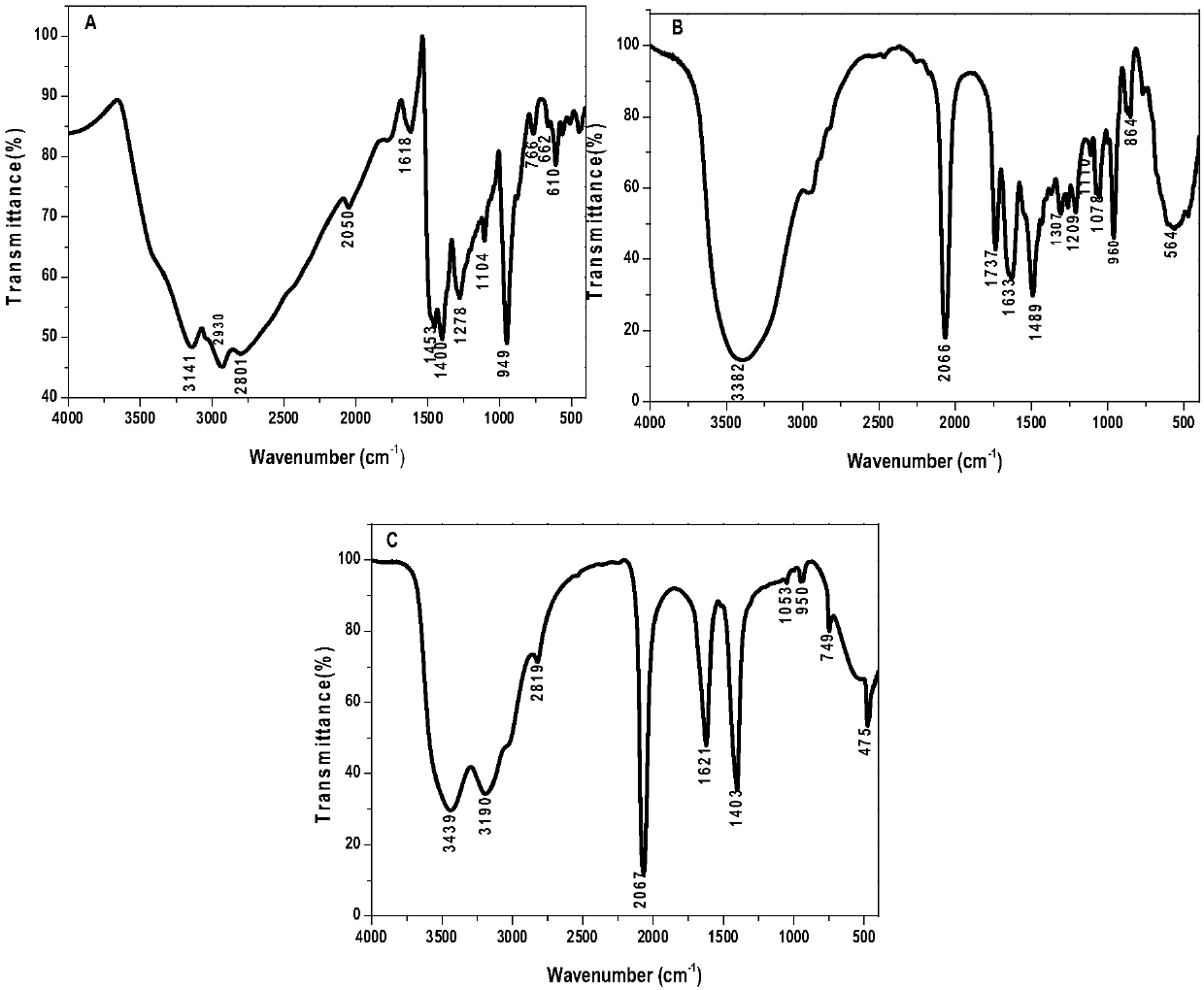

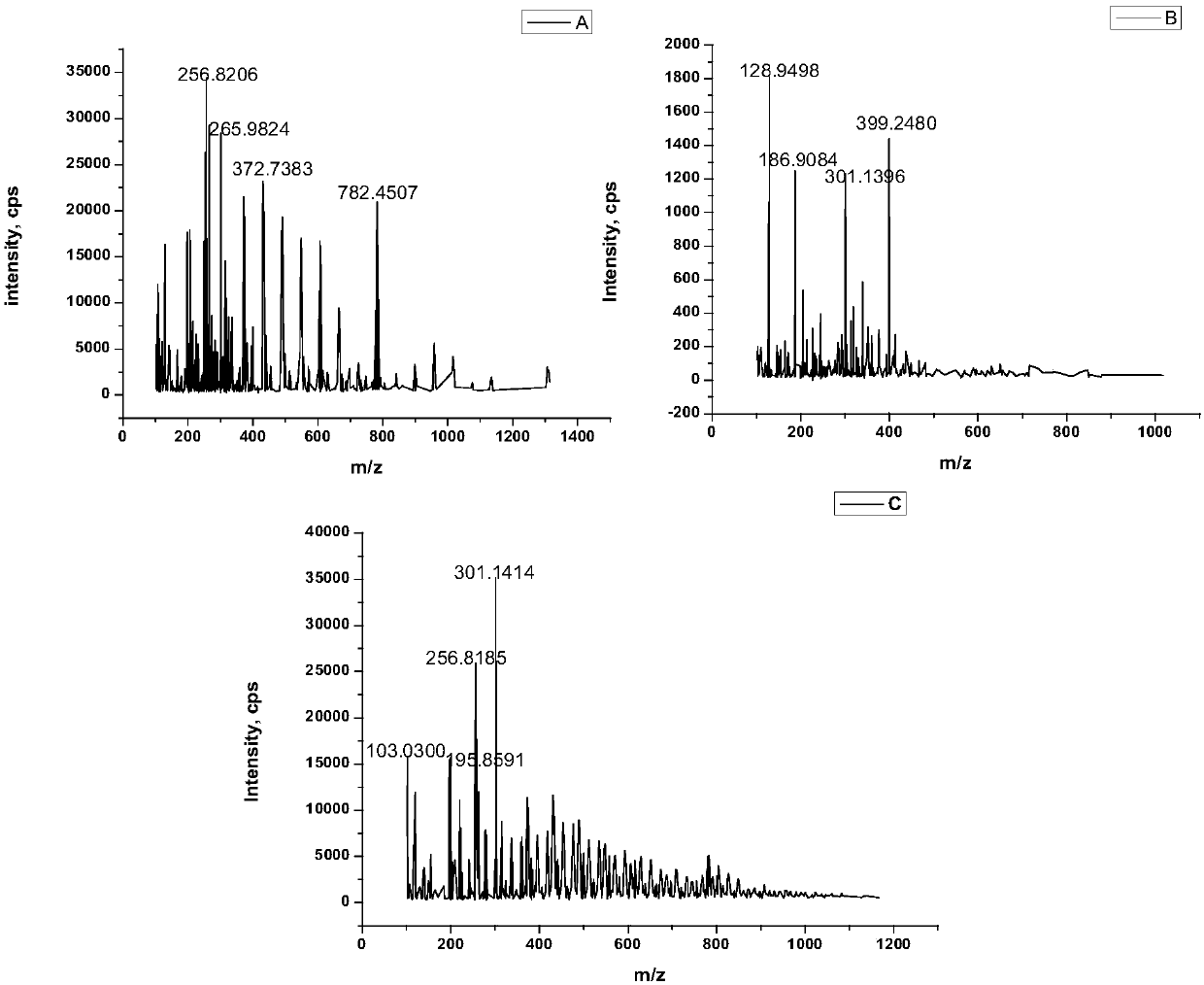

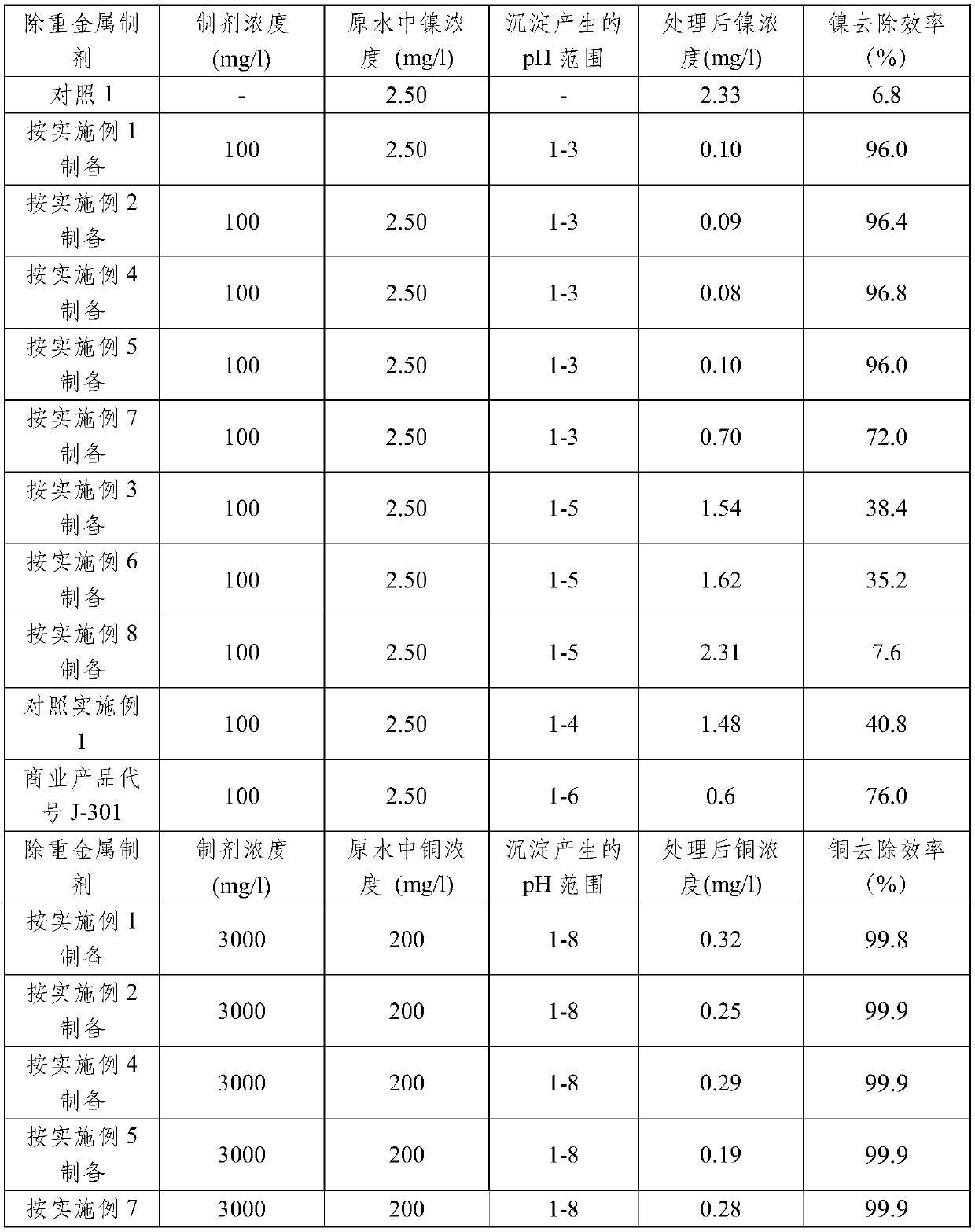

ActiveCN110203991AReduce alkalinityAvoid it happening againOther chemical processesWater contaminantsEthylenediamineIndustrial effluent

The invention relates to a heavy metal removal preparation, and a synthesis method and an application thereof. The synthesis method comprises the following steps: one-pot synthesis of the heavy metalremoval preparation from dichloroalkane, ammonia and carbon disulfide in the presence of an alkaline substance especially a weakly alkaline substance, and distillation off of the remaining ammonia. The synthesis of the heavy metal removal preparation of the invention adopts the dichloroalkane and ammonia with low prices as raw materials, and is obtained through a two-step or one-step reaction by the one-pot process, so the cost is low, and the yield is high. The synthesis method breaks through the abuses and defects of the prior art using ethylenediamine as a raw material, and significantly reduces the production cost; and the prepared heavy metal removal preparation still maintains a stable heavy metal removal performance under an extremely low pH condition, and plays a great role in theremoval of heavy metals from wastewater in actual electroplating and smelting industries.

Owner:BEIJING NORMAL UNIVERSITY

A method of preparing high-purity 1-pentene

ActiveCN104557409AAdd recovery unitEasy to separateChemical modification purification/separationAlkaneButene

A method of preparing high-purity 1-pentene is disclosed. The method includes steps of: 1) rectifying a raw material that is raffinate C5 after extraction and separation of diolefine and isopentene so as to separate and remove heavy components, obtaining an enriched 1-pentene fraction from the tower top, and discharging heavy components from the tower bottom; 2) subjecting the enriched 1-pentene fraction obtained from the tower top in the step 1) to precision rectification so as to remove light components, obtaining C5 alkanes and other light components from the tower top, and obtaining a 1-pentene crude product from the tower bottom; 3) subjecting the 1-pentene crude product obtained in the step 2) to isomerization through a sulfo-group cation exchange resin fixed catalytic bed to convert 2-methyl-1-butene that is difficult to separate in the crude product into 2-methyl-2-butene that is easy to separate; and 4) feeding isomerization products obtained in the step 3) to a rectification tower, and purifying to obtain the 1-pentene having purity higher than 98%. By improving process steps, the method simplifies the process, reduces the production cost, and improves the economical efficiency of the process of preparing the high-purity 1-pentene.

Owner:CHINA PETROLEUM & CHEM CORP +1

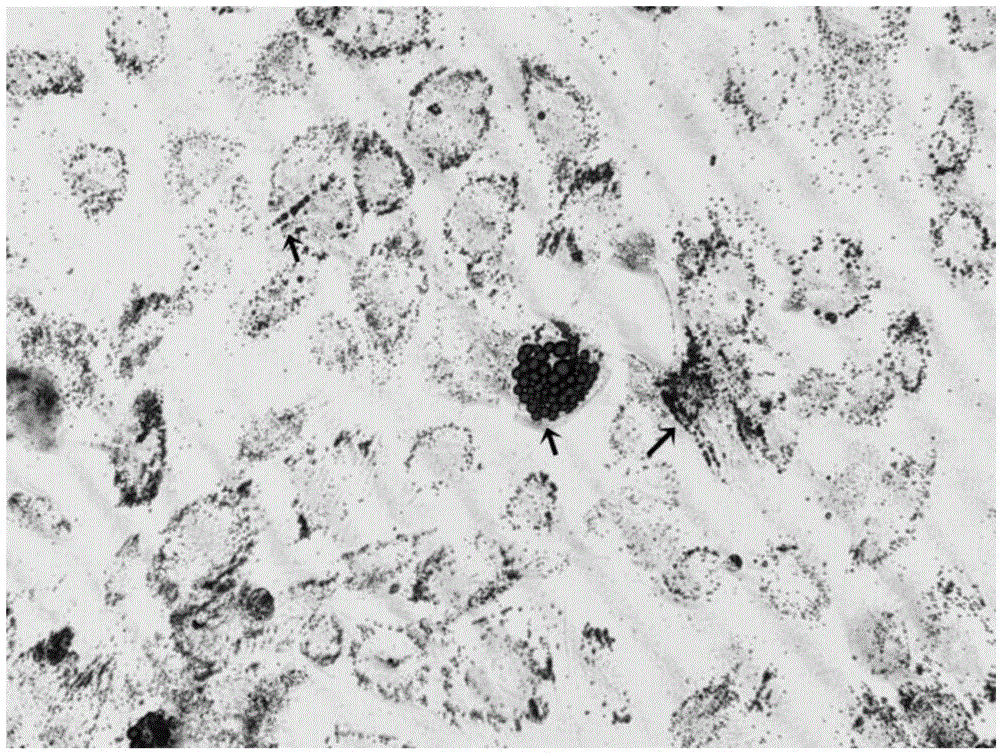

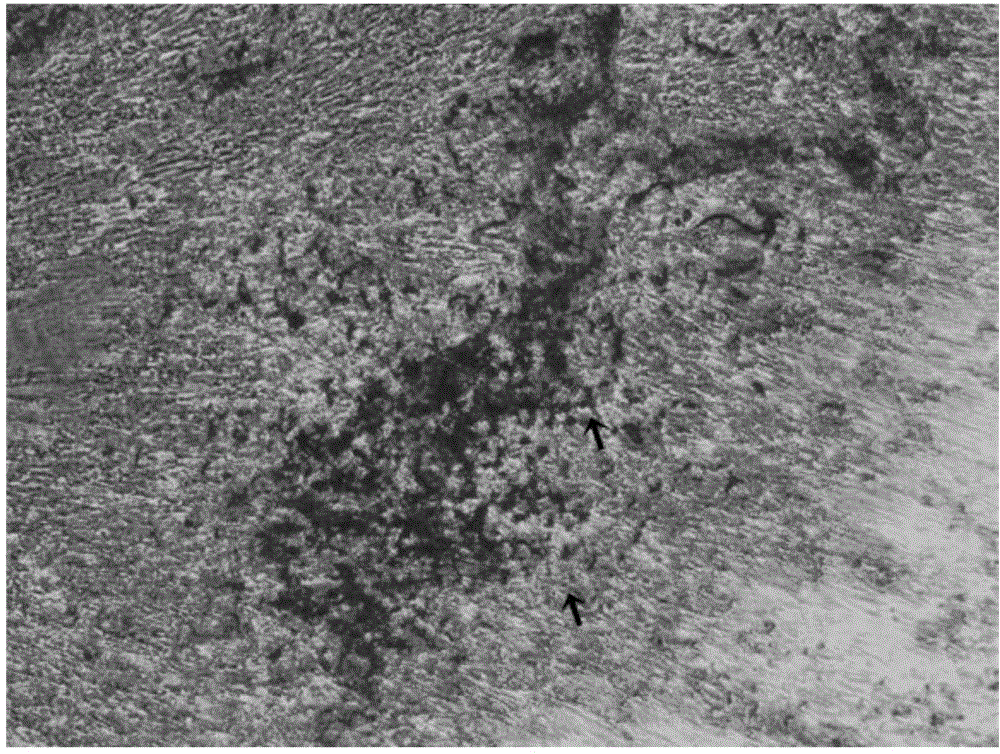

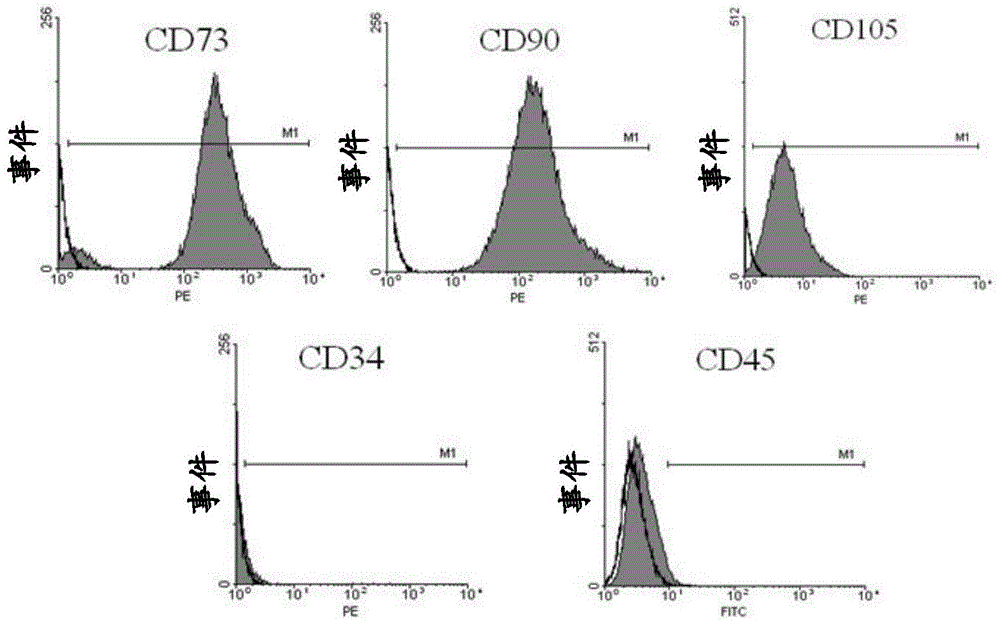

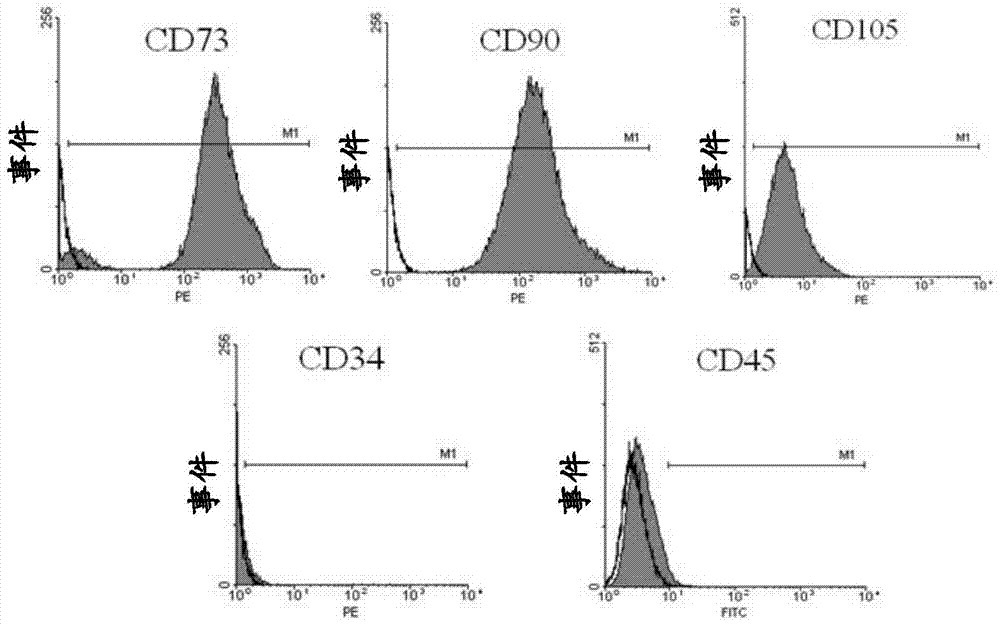

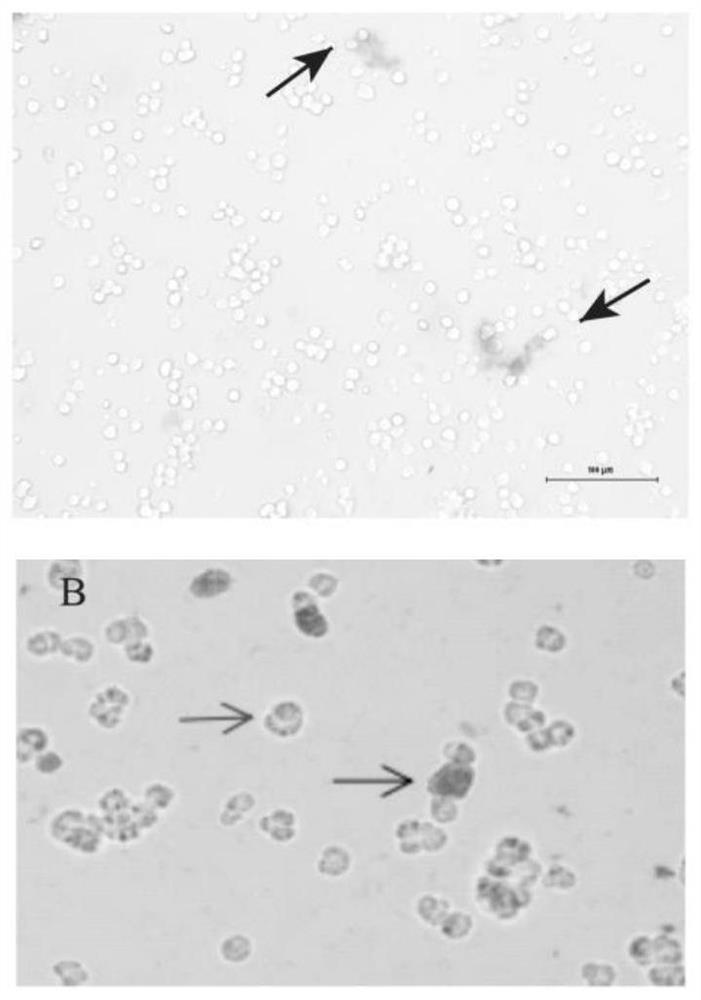

Method of separating and cultivating umbilical cord mesenchymal stem cells

ActiveCN104450609AImprove acquisitionReduce separation costsSkeletal/connective tissue cellsUmbilical cord tissueHyaluronidase

The invention belongs to the biomedical field and particularly belongs to the field of stem cells. The invention provides a method of separating UC-MSCs (umbilical cord mesenchymal stem cells). The method comprises the following steps: 1) mixing umbilical cord tissue pieces with pancreatin and collagenase to incubate; and 2) adding hyaluronidase to incubate.

Owner:BGI SHENZHEN CO LTD

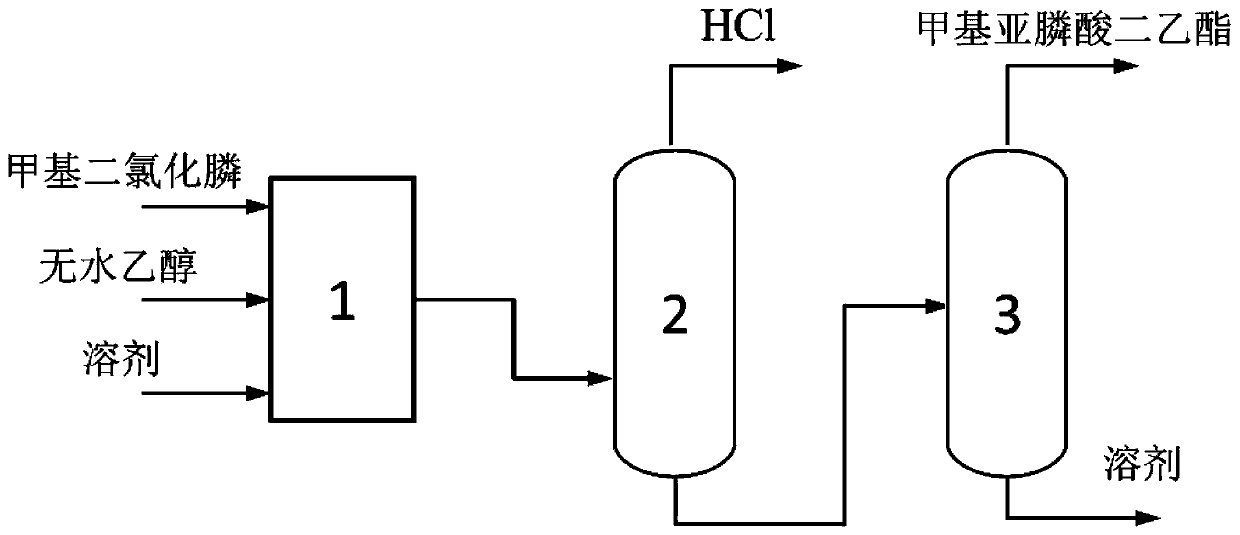

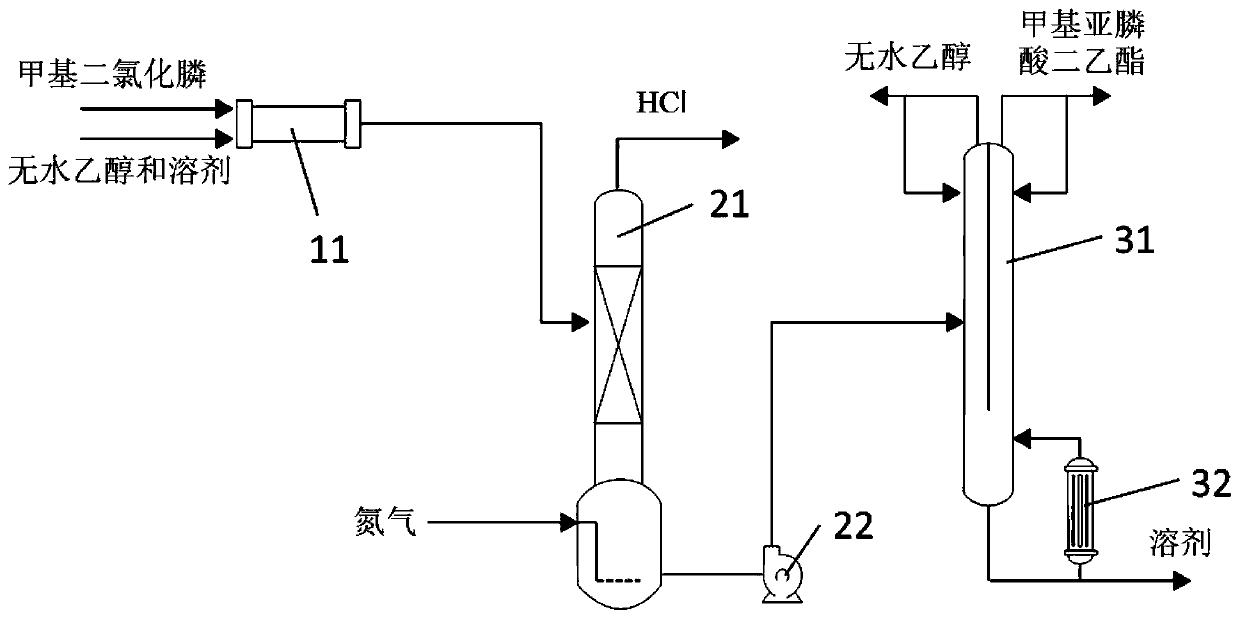

Synthesis method and synthesis device of diethyl methylphosphite

InactiveCN111574561AAvoid it happening againEasy to separateGroup 5/15 element organic compoundsSolventMethyl palmoxirate

The invention relates to a synthesis method and a synthesis device of diethyl methylphosphite. The synthesis method comprises the following steps: (1) mixing methyl phosphine dichloride, absolute ethyl alcohol and a solvent to carry out a synthesis reaction; (2) carrying out reduced pressure deacidification treatment on the reaction solution obtained in the step (1); and (3) separating and purifying the deacidified reaction solution obtained in the step (2) to obtain diethyl methylphosphite. According to the synthesis method, an acid-binding agent is not needed, hydrogen chloride gas generatedby the synthesis reaction can be discharged through reduced-pressure deacidification treatment, the generation of solid waste residues containing acid-binding agent hydrochloride is avoided, the separation and treatment of the solid waste residues are reduced, and the dosage of ethanol is reduced by adding a solvent, so that the ethanol does not need to play a role as a solvent, the energy consumption is reduced, the resources are saved, the process is high in yield, simple to operate and environment-friendly, and the atom economy is good.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

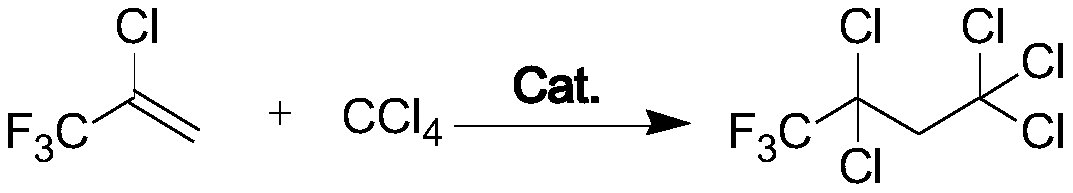

Preparation method of 1,1,1,3,3-pentachloro-4,4,4-trifluorobutane

InactiveCN110372473AIncrease production costIncreased separation costOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationTelomerizationMedicinal chemistry

The invention discloses a preparation method of 1,1,1,3,3-pentachloro-4,4,4-trifluorobutane. The preparation method comprises the steps: adopting 2-chloro-3,3,3-trifluoropropene and carbon tetrachloride as raw materials, and synthesizing 1,1,1,3,3-pentachloro-4,4,4-trifluorobutane in the presence of a telomerization catalyst, a catalytic assistant and a reducing agent. The invention provides a synthetic route with high telomerization reaction efficiency, and the preparation method is mainly applied to preparation of 1,1,1,3,3-pentachloro-4,4,4-trifluorobutane.

Owner:XIAN MODERN CHEM RES INST

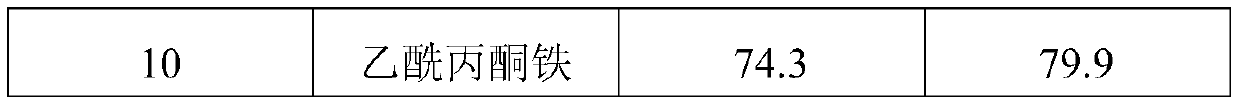

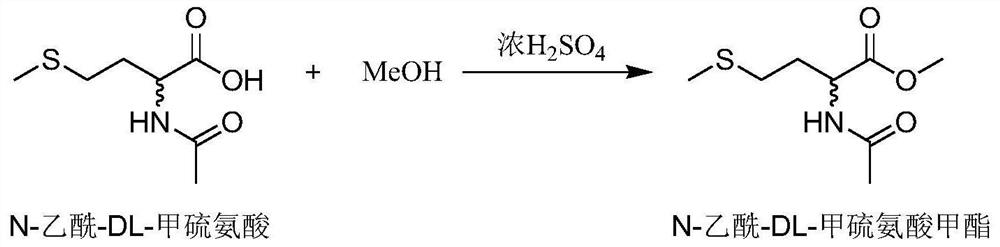

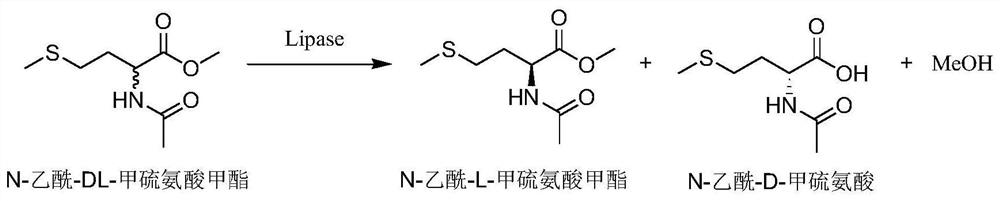

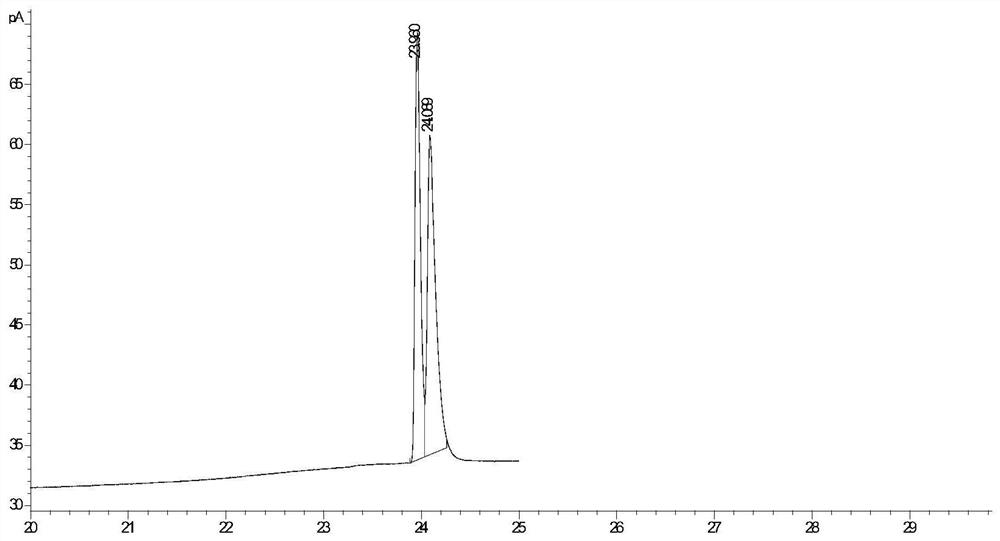

Application of a lipase in splitting n-acetyl-dl-methionine methyl ester

ActiveCN109628544BImprove efficiencyMild conditionsHydrolasesMicroorganism based processesEnzyme GeneRecombinant escherichia coli

The invention provides an application of a lipase in splitting N-acetyl-DL-methionine methyl ester, the amino acid sequence of the lipase is shown in SEQ ID NO.1, and its coding gene is shown in SEQ ID NO .2 shown. The lipase gene of the present invention can be connected with an expression vector to construct an intracellular expression recombinant plasmid containing the gene, and then transformed into an E. coli strain to obtain a recombinant E. coli engineering bacterium; the recombinant E. coli is subjected to cell crushing, separation and purification to obtain a recombinant fat Enzyme; the recombinant lipase has the ability to catalyze the splitting of N-acetyl-DL-methionine methyl ester, and can obtain N-acetyl-L-methionine methyl ester with an enantiomeric excess value of >99% and a conversion rate of 51.2 %.

Owner:ZHEJIANG UNIV OF TECH

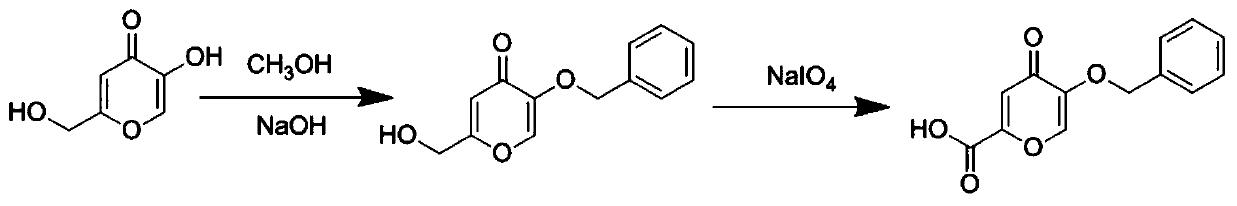

A kind of preparation method of 5-benzyloxy-4-oxo-4h-pyran-2-carboxylic acid

ActiveCN105481812BIncreased separation costIncrease production costOrganic chemistryKojic acidWastewater

The present invention discloses a 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid preparation method comprising the following steps: adding kojic acid, benzyl chloride and methanol benzyl chloride into a reaction vessel, and heating for reflux reaction for 16 to 18 hours; distilling under reduced pressure, evaporating the solvent to dryness, and cooling to room temperature; adding methanol and water, stirring, washing, filtering and drying to obtain an intermediate; and adding the intermediate and water into the reaction vessel, reducing the temperature to 0 DEG C to -10 DEG C, adding sodium periodate, controlling the temperature to be not higher than 5 DEG C, then adding dropwise a proper amount of water, stirring for 5-15 minutes, heating to 12 DEG C-22 DEG C, stirring for reaction for 2.5 to 3.5 hours, extracting with ethyl acetate, layering, drying, filtering and drying to obtain white solid 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid. The new 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid preparation method is provided, does not produce large amounts of chromium-containing waste water, prevents severe environmental pollution, and can achieve industrial production.

Owner:CHONGQING TIANYI HENGHUA TECH CO LTD

A method for preparing high-purity 1-pentene

ActiveCN104557410BAdd recovery unitIncreased separation costDistillation purification/separationChemical modification purification/separationAlkaneDistillation

A method for preparing high-purity 1-pentene. The process includes: using the raffinated C5 after diolefins and isopentene have been extracted and separated as raw material for rectification and separation to remove heavy components, the top of the tower is enriched with 1-pentene cuts, and the heavy components are discharged from the bottom of the tower; by process 1 ) The fraction enriched in 1-pentene obtained at the top of the tower is subjected to precise rectification to remove light components, and the top of the tower obtains carbon penta-alkanes and other light components, and the crude product of 1-pentene is obtained in the bottom of the tower; by process 2) The crude product of 1-pentene is etherified with methanol to remove the difficult-to-separate 2-methyl-1-butene in the crude product; the ether product obtained in process 3) is sent to a refining tower for purification to obtain More than 98% 1-pentene. The invention improves the process flow, simplifies the process, reduces the production cost, and improves the economic efficiency of the process for preparing high-purity 1-pentene.

Owner:CHINA PETROLEUM & CHEM CORP +1

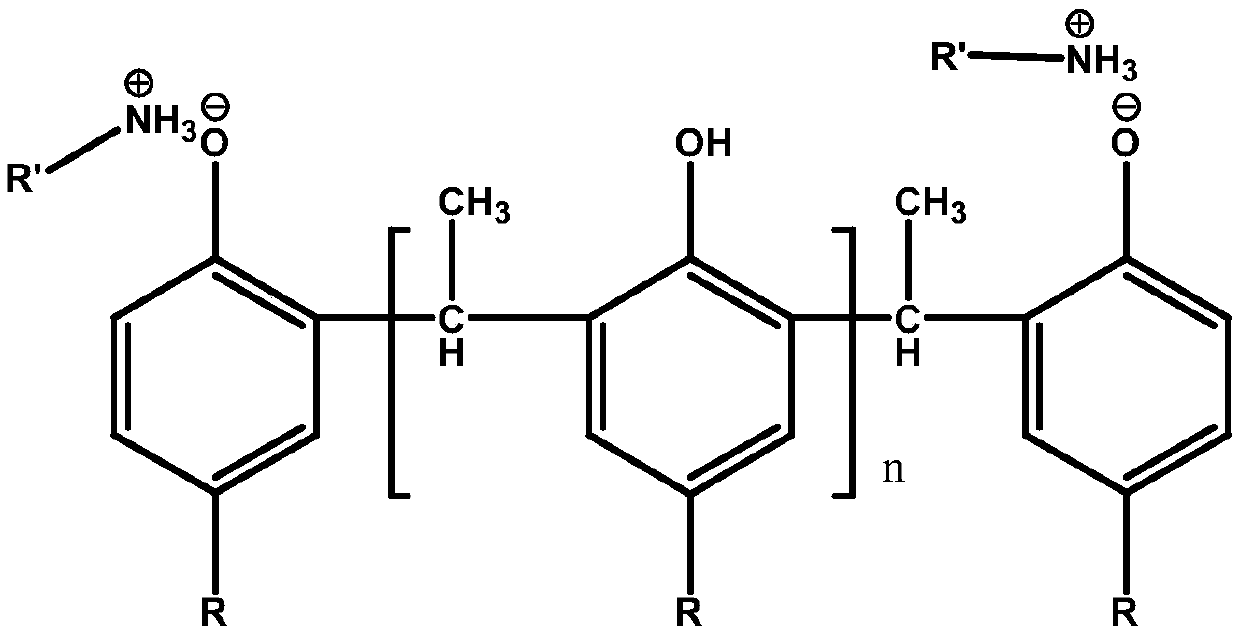

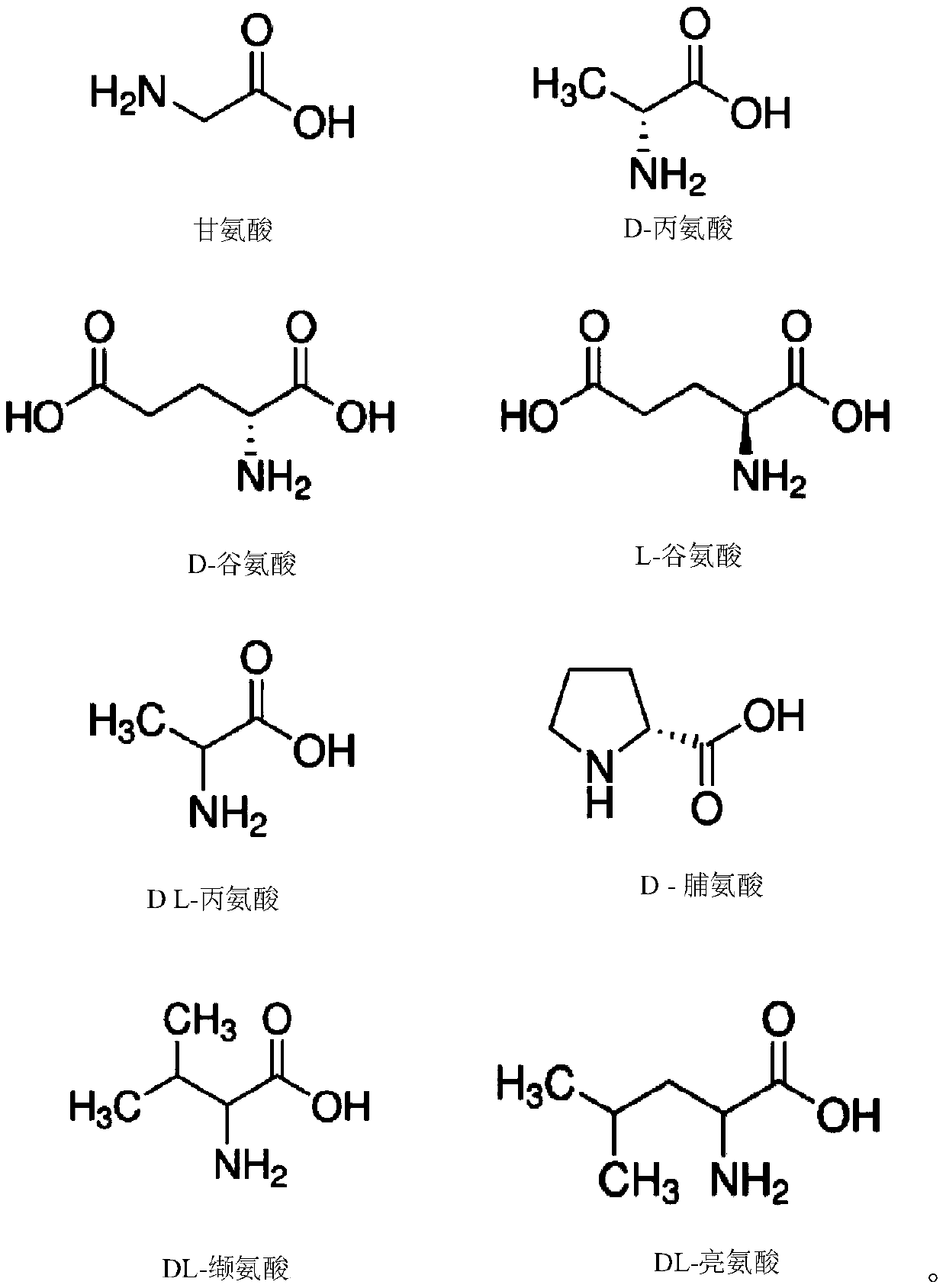

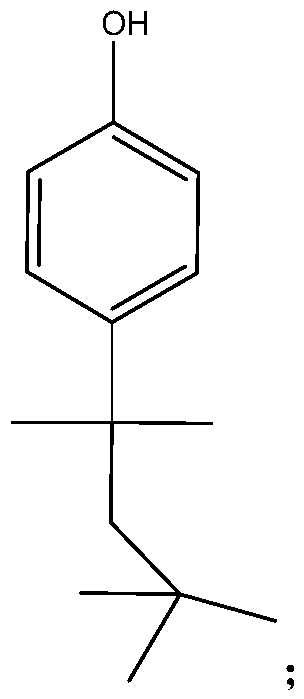

Amino acid modified alkylphenol-formaldehyde resin and preparation method thereof

InactiveCN110862499AImprove initial viscosityImprove long-lasting stickinessRubber materialPolymer science

The invention provides amino acid modified alkylphenol-formaldehyde resin. The invention further provides a preparation method of the amino acid modified alkylphenol-formaldehyde resin, a complex separation process of DL mixed amino acid is avoided, the modified alkylphenol-formaldehyde resin has extremely high tackifying performance, and the tackifying durability and damp-heat viscosity performance of the modified alkylphenol-formaldehyde resin are excellent. The amino acid modified alkylphenol-formaldehyde resin also has the following advantages that when raw materials are used, the condition of using solid formaldehyde is provided, so that part of formaldehyde aqueous solution is replaced, and the wastewater amount is greatly reduced; the amino acid modified alkylphenol-formaldehyde resin is selected, so that the branching degree of a product can be greatly improved, and the tackifying performance of the resin is improved; amino acid not only contains amino, carboxyl and long-chainalkane functional groups, but also can effectively improve the intermiscibility of resin and rubber materials and reduce the migration rate, so that the lasting viscosity of rubber sheets is improved.

Owner:SHANDONG YANGGU HUATAI CHEM

A method for isolating and cultivating umbilical cord mesenchymal stem cells

ActiveCN104450609BHigh activityIncreased separation costSkeletal/connective tissue cellsUmbilical cord tissueHyaluronidase

The invention belongs to the biomedical field and particularly belongs to the field of stem cells. The invention provides a method of separating UC-MSCs (umbilical cord mesenchymal stem cells). The method comprises the following steps: 1) mixing umbilical cord tissue pieces with pancreatin and collagenase to incubate; and 2) adding hyaluronidase to incubate.

Owner:BGI SHENZHEN CO LTD

Catalyst for preparing 1,3,3,3-tetrafluoropropene from 1,1,1,3,3-pentafluoropropane

ActiveCN106902849BLow costReduce inactivationPreparation by hydrogen halide split-offPhysical/chemical process catalysts1,3,3,3-TetrafluoropropenePentafluoropropane

The invention discloses a catalyst for preparing 1,3,3,3-tetrafluoropropene from 1,1,1,3,3-pentafluoropropane, the composition of which is M x O y / AlF 3 , where the carrier AlF 3 It has an alpha phase structure and a specific surface area greater than 150m 2 ·g ‑1 , active carrier with pore size distribution concentrated in 15nm~40nm, M x O y For MgO, Fe 2 O 3 ,Co. 2 O 3 Or one of CuO, M x O y and AlF 3 The molar ratio is 1:5~50. The preparation method of the catalyst is: using active α-phase AlF with large specific surface area and mesoporous structure 3 As a carrier, the soluble salt of any element such as Mg, Fe, Co or Cu is loaded with equal amounts of impregnation method, and then dried and roasted at high temperature to form a catalyst. The catalyst in the present invention has excellent performance, does not need to use expensive precious metal compounds in the preparation process, has low cost and high activity. When reacting at 280°C, the conversion rate of 1,1,1,3,3-pentafluoropropane can reach 70%. Above, the catalyst has a long life, can operate stably for 360 hours, and does not need to introduce diluent gas during the reaction process, so it has industrial application value.

Owner:XIAN MODERN CHEM RES INST

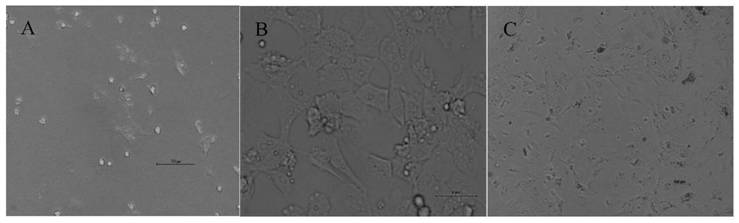

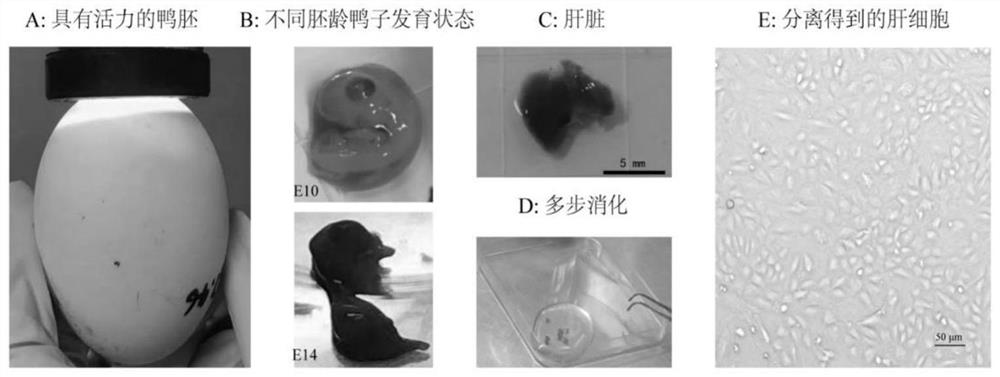

Duck embryo primary hepatocyte separation culture method

ActiveCN113957035AFully digestedAvoid complex operationsCell dissociation methodsVertebrate cellsBiotechnologyEnzyme digestion

The invention relates to the field of cell culture, in particular to a duck embryo primary hepatocyte separation culture method. The method comprises the following steps: disinfecting shells of duck embryos, and taking 13-15-day-old duck embryos under an aseptic condition; separating the liver of the duck embryo, removing gall bladder, and soaking and washing the obtained liver in a D-Hank's buffer solution; removing loose connective tissues and liver envelopes adhered to the periphery of the liver, and soaking and washing the obtained small pieces of liver tissues in D-Hank's buffer solution; performing multi-step digestion; and re-suspending the obtained cells, sieving the cells with a 70-[mu]m cell sieve, and inoculating the cells into a culture bottle for culture. According to the invention, a simple, economical and rapid duck embryo primary hepatocyte separation method is established from the selection of the day age of the duck embryo, the combination of a mechanical method and an enzyme digestion method for tissues and the like.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

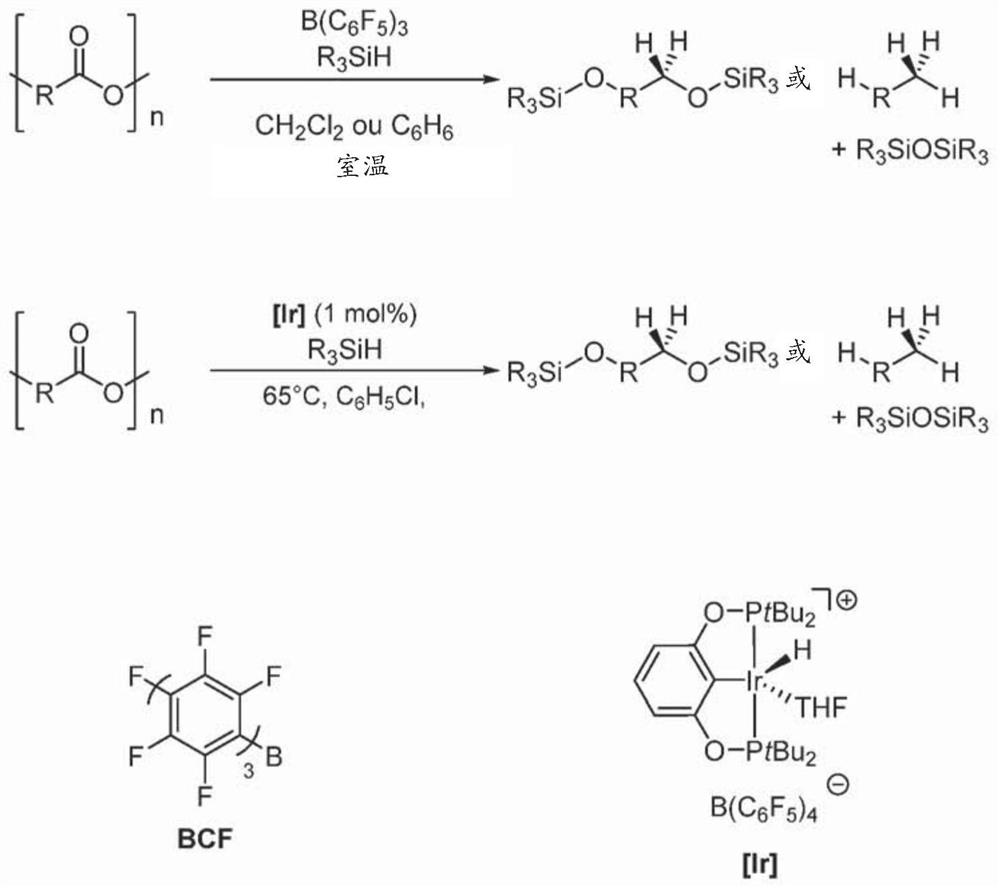

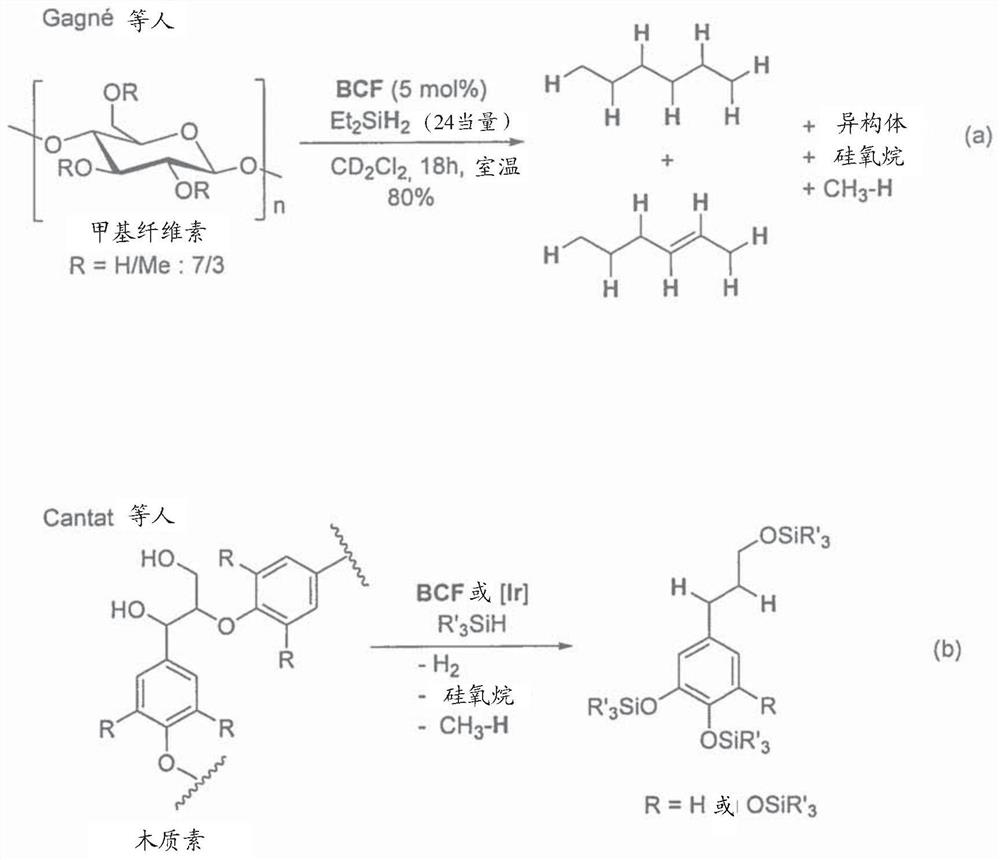

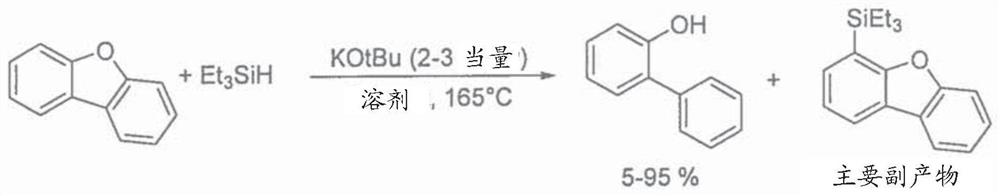

Method for depolymerising oxygenated polymer materials by nucleophilic catalysis

ActiveCN112673058AHigh purityEasy to purifyOrganic compound preparationPlastic recyclingFertilizerChemistry

The present invention relates to a method for depolymerising oxygenated polymer materials, in particular by nucleophilic catalysis, and to the use of said method in the recycling of plastic materials and the preparation of aromatic and aliphatic compounds that can be used as fuel, synthesis intermediates, raw materials in the construction sector, and in the petrochemical, electrical, electronic, textile, aeronautical, pharmaceutical, cosmetic and agrochemical industries. The present invention also relates to a method for manufacturing fuels, electronic components, plastic polymers, rubber, medicines, vitamins, cosmetics, perfumes, food products, synthetic yarns and fibres, synthetic leathers, glues, pesticides and fertilisers, comprising (i) a step of depolymerisation of oxygenated polymer materials according to the method of the invention and, optionally, (ii) a step of hydrolysis and, optionally, (iii) a step of functionalisation and / or defunctionalisation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

The method for preparing high-purity 1-pentene

ActiveCN104557409BAdd recovery unitEasy to separateChemical modification purification/separationAlkaneButene

The method for producing high-purity 1-pentene, the process includes: using the raffinate carbon five after extraction and separation of diolefins and isopentene as raw material to rectify and separate and remove heavy components, and enrich 1-pentene at the top of the tower Distillate, the heavy component is discharged from the tower bottom; the fraction enriched in 1-pentene obtained from the process 1) at the top of the tower is subjected to precise rectification to remove light components, and carbon penta-alkanes and other light components are obtained at the top of the tower, and obtained at the bottom of the tower The crude product of 1-pentene; the crude product of 1-pentene obtained by process 2) isomerized through a fixed-bed catalytic bed of sulfonic acid-based cation exchange resin, so that the difficult-to-separate 2-methyl-1-in the crude product Butene is converted into 2-methyl-2-butene which is easier to separate; the isomerization product obtained in process 3) is sent to a refining tower for purification to obtain more than 98% 1-pentene. The invention improves the process flow, simplifies the process, reduces the production cost, and improves the economic efficiency of the process for preparing high-purity 1-pentene.

Owner:CHINA PETROLEUM & CHEM CORP +1

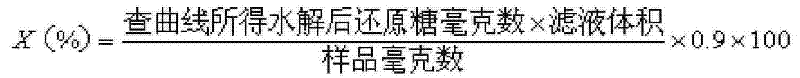

Comprehensive Utilization Method of Corn Cob

ActiveCN101628920BEasy to separatePromote conversionSugar derivativesBiofuelsSocial benefitsMolecular materials

The invention provides a comprehensive utilization method of corn cob, which effectively separates hemicellulose, lignin and cellulose contained in a reproducible biological resource of corn cob in a reasonable process order at low cost and high efficiency, and makes full use of every type of biomass components, thereby solving the problem of utilization of residue in the biomass refining process of preparing ethanol and butanol by extracting xyio-oligosacchandes and enzymolysis from the corn cob in the prior art, and making reasonable and effective use of main components of biomass contained in the corn cob; particularly, the lignin can substitute partial petrochemical materials to prepare modified high-molecular materials, thereby reducing the cost of high-molecular materials and saving the energy consumption of petrochemical materials to bring great social benefit; in addition, the comprehensive utilization method of corn cob is featured by simple processing technique, easy implementation and favorable effect.

Owner:重庆辉泰化工销售有限公司

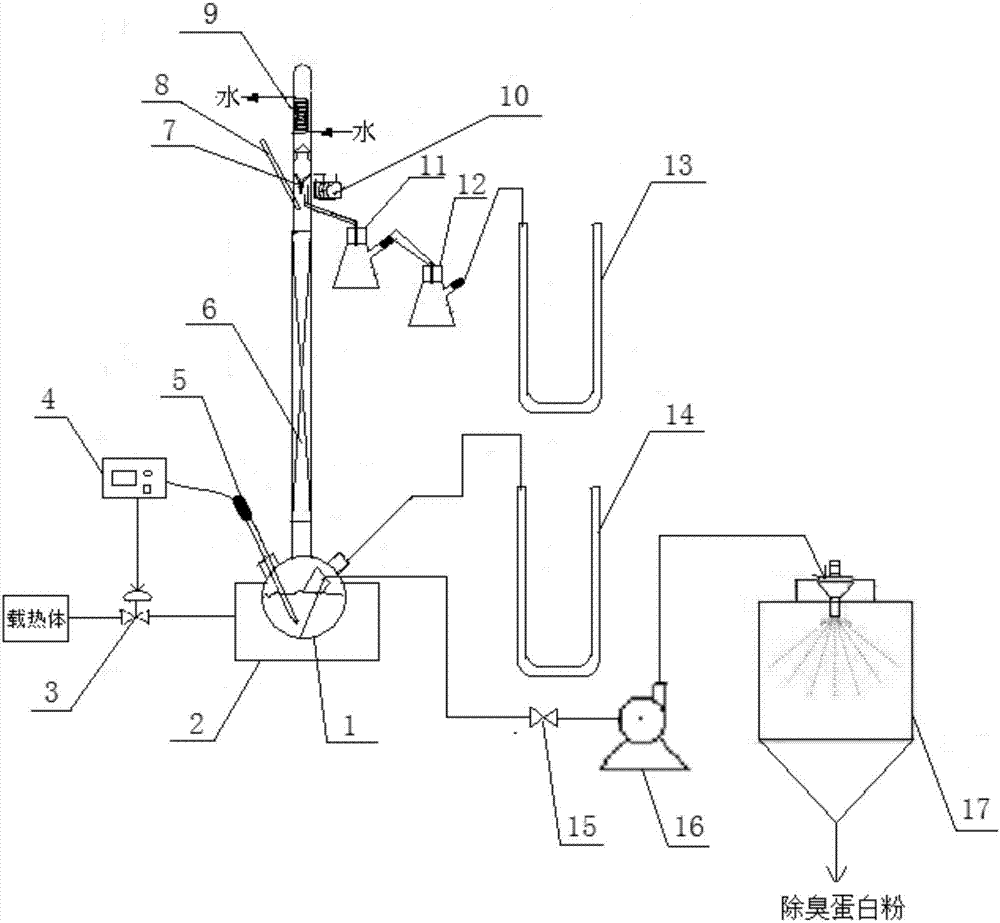

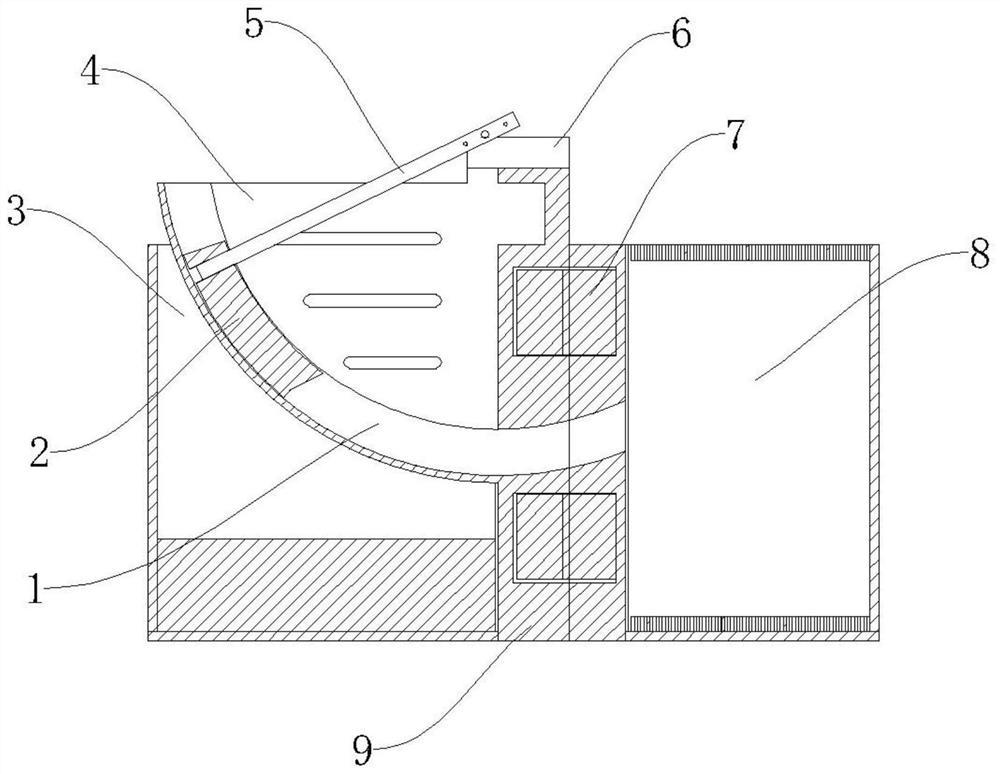

Device for removing volatile odor from sludge protein solution

PendingCN107243163AMonitor temperature in real timeNo loss of puritySpecific water treatment objectivesDistillation in boilers/stillsProtein solutionElectrical resistance and conductance

The invention provides a device for removing volatile odor from a sludge protein solution. The device for removing the volatile odor from the sludge protein solution comprises an evaporating device, a rectifying device and a odorant liquid receiving device, wherein the evaporating device comprises a temperature controller, a tower kettle and a heater on the outer side of the tower kettle; a thermoresistor thermometer is arranged inside the tower kettle; the thermoresistor thermometer interacts with the temperature controller; the heater is connected with a heat carrier pipe; a pneumatic actuator is arranged on the heat carrier pipe; the pneumatic actuator is connected with the temperature controller; a rectifying interface is further formed in the tower kettle; the rectifying interface is connected with the rectifying device; the rectifying device is connected with the odorant liquid receiving device. The device for removing the volatile odor from the sludge protein solution, provided by the invention, does not destroy sludge protein and reduce the purity thereof while sludge protein deodorization is achieved.

Owner:YULIN UNIV

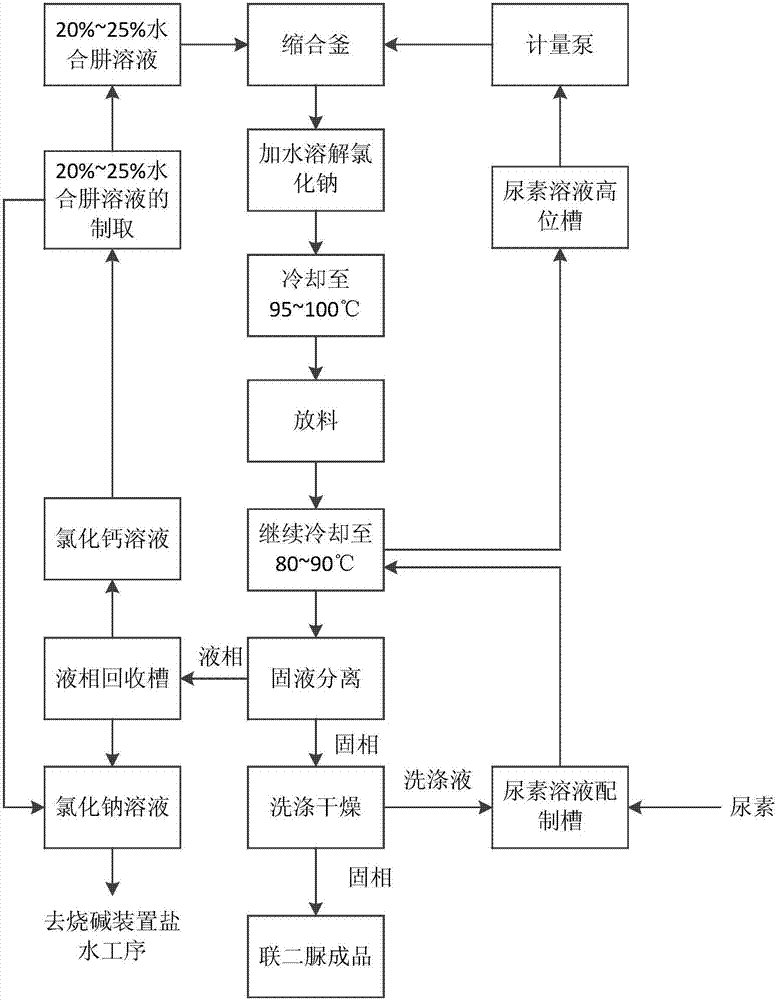

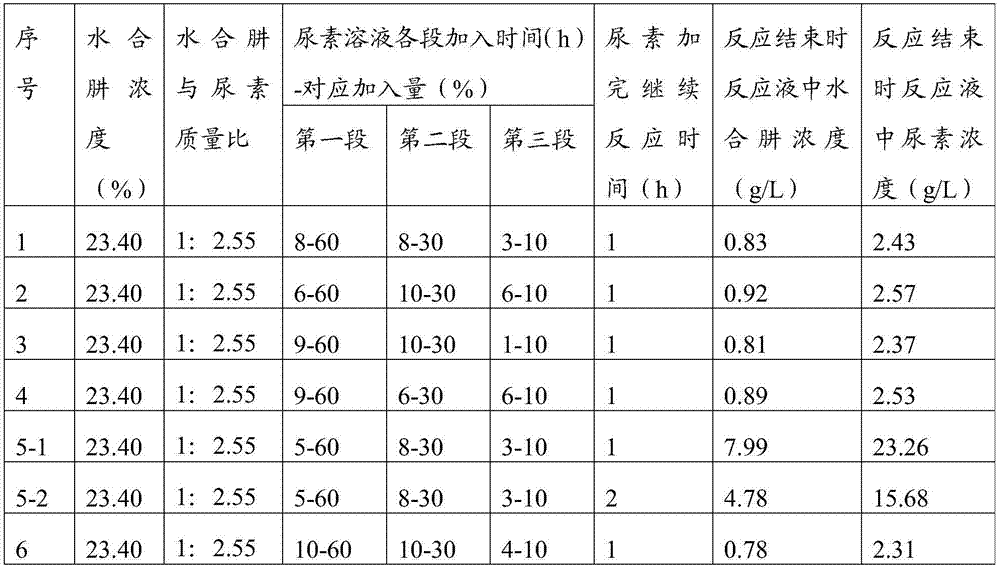

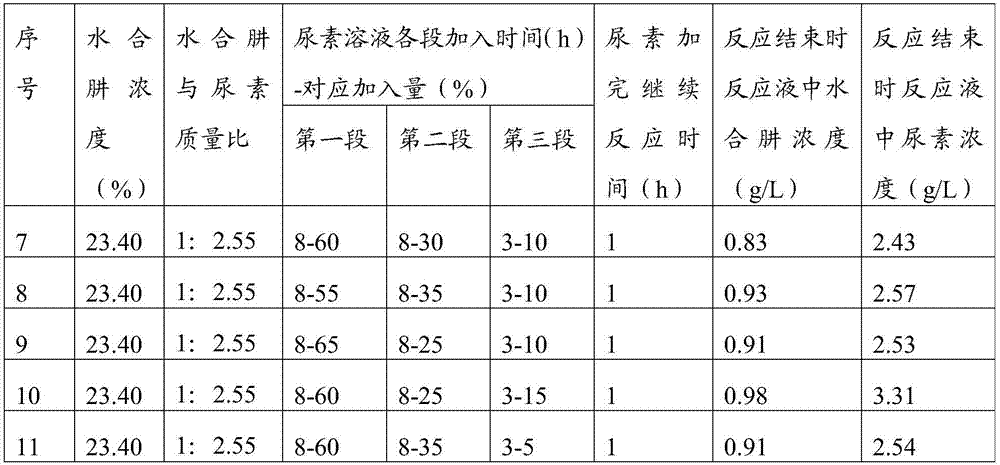

A kind of preparation method of biurea

The invention discloses a preparation method of biurea, wherein the preparation method comprises the steps: firstly, preparing a 20%-25% hydrazine hydrate solution as a raw material; followed by, adding a urea solution into a condensation kettle in a successive subsection manner, and carrying out condensation reaction, wherein the mass ratio of hydrazine hydrate to urea is less than or equal to 1:2.55, and the addition way of the urea solution is divided into three sections; after addition of urea is completed, continuing to carry out reaction for a period of time until the concentration of residual hydrazine hydrate in a reaction liquid in the condensation kettle is less than or equal to 1 g / L, stopping heating of the condensation kettle, and then adding water to dissolve sodium chloride precipitated in the condensation reaction process; and cooling, and then successively carrying out discharging, solid-liquid separation, and washing and drying treatment to obtain the diurea product. The preparation method of the diurea makes the preparation process of the diurea more energy saving and more efficient and makes the cost lower, impurities in the prepared diurea are fewer, and the purity is higher.

Owner:QINGHAI SALT LAKE IND

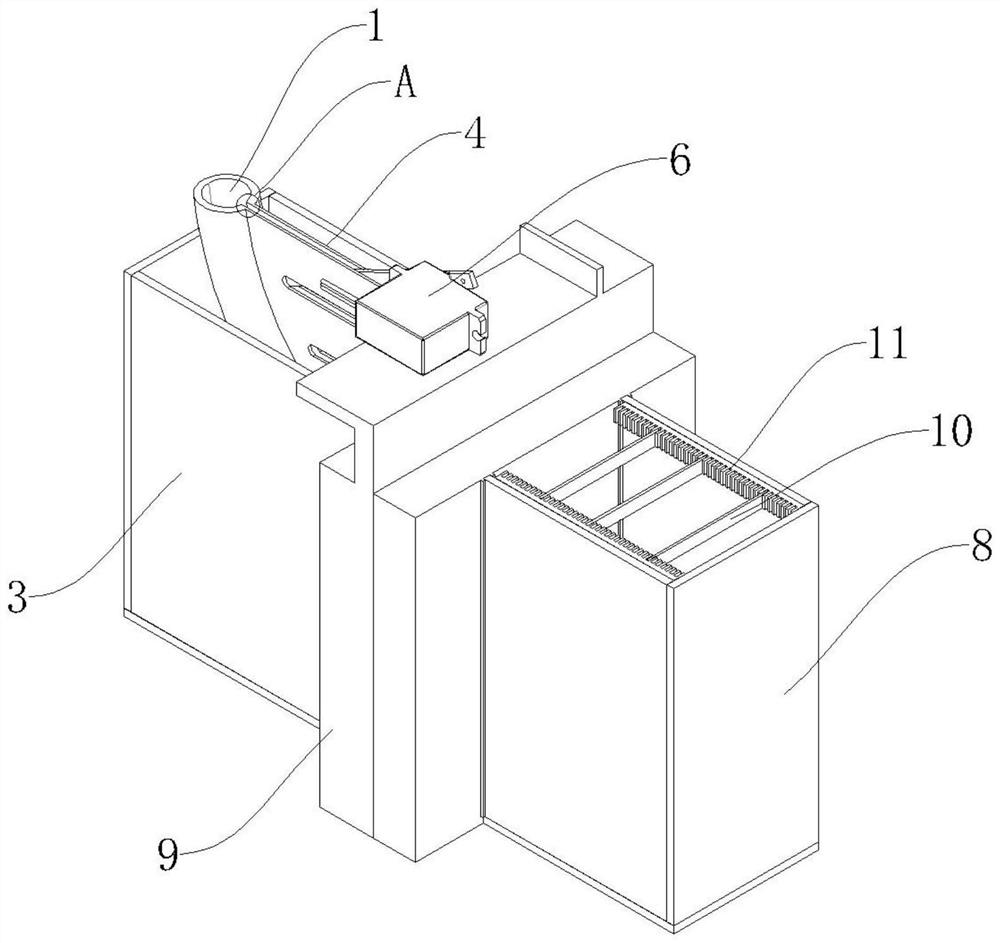

Bidirectional magnetic projection automatic separation device for plastic waste

ActiveCN113134921ASimple designMake up for the sharp cutsPlastic recyclingMechanical material recoveryPlastic wasteControl theory

The invention provides a bidirectional magnetic projection automatic separation device for plastic waste. The bidirectional magnetic projection automatic separation device comprises a separation box used for containing a medium solution. the bidirectional magnetic projection automatic separation device further comprises a feeding mechanism and an axial magnetizing annular magnet group, the axial magnetizing annular magnet group is arranged between the feeding mechanism and the separation box, the feeding mechanism comprises a feeding channel and a pendulum bob, wherein the discharging end of the feeding channel penetrates through the annular magnet group and communicates with the separation box, the pendulum bob is arranged in the feeding channel in a sliding mode and can push materials in the feeding channel to the separation box, the end face of the discharging end of the feeding channel is perpendicular to the central axis direction of the annular magnet group, the end face of the pushing end of the pendulum bob is of a molded surface structure consistent with the end face of the discharging end, and the center of the end face of the discharging end is close to or located on the central axis of the annular magnet group. The bidirectional magnetic projection automatic separation device is high in separation precision, high in separation recovery rate and large in single-time separation amount, a mixture of various plastic wastes can be separated, the working efficiency is greatly improved, and the separation cost is reduced.

Owner:ZHEJIANG UNIV

A kind of separation and extraction method of squalene in mixed tocopherols

ActiveCN103288571BGuaranteed purityGuaranteed RecoveryAdsorption purification/separationAlcoholElution

The invention provides a method for separating and extracting squalene in mixed tocopherols. The method comprises steps of: filling silochrom with the meshes of 100-200 into a chromatographic column, adopting an elution solvent to elute and compact the silochrom, then feeding the tocopherols into the chromatographic column according to a proper ratio, and separating the squalene from natural vitamin E through utilizing column chromatography. By adopting the separating and extracting method, the technological process is simple, the purity and recovery rate of the squalene can be improved to the maximum extent through utilizing a gradient elution method, silicagel columns can be well regenerated through utilizing strong polar solvents such as methyl alcohol and the like, and the method has the advantages of large solvent usage, easiness in recycling, small consumption and small environmental pollution.

Owner:NINGBO DAHONGYING BIO ENG

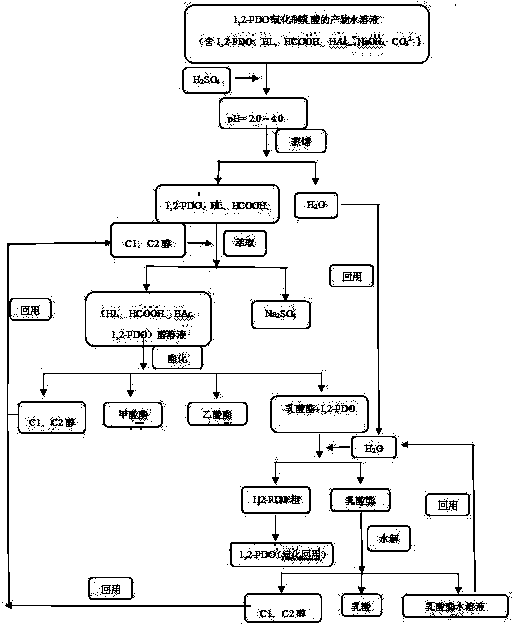

Product separation process for preparing lactic acid by means of oxidation of 1,2-propanediol

ActiveCN107857700ANo emissionsIncreased energy costsOrganic compound preparationCarboxylic compound separation/purificationHydrolysisPropanediol

The invention provides a product separation process for preparing lactic acid by means of selective catalytic oxidation of 1,2-propanediol (1,2-PDO). A separation object is a 1,2-PDO oxidized lactic acid product mixture solution which contains a NaOH aqueous solution, unreacted 1,2-PDO, lactic acid, formic acid, acetic acid and carbonate. The separation process includes the following steps of acidification, extraction, esterification, distillation under reduced pressure and hydrolysis. According to the separation process, 1,2-PDO oxidation mixtures are completely separated to obtain high-purity lactic acid and lactic anhydride, the yield is high, by adopting a ester extracting agent, the separation energy consumption and the equipment input cost are reduced, separated and added substancescan be recycled and reutilized, and the separation process completely causes no waste water discharge, saves the cost and is efficient and environmentally friendly.

Owner:南京大学扬州化学化工研究院

Method for separating gas

ActiveCN102121369BReduce separation costsAchieve natural separationFluid removalLighter than airResistor

The invention provides a method for separating gas. The method comprises the following steps of: (1) building enclosed wall bodies at all exits of an isolated worked out section to fully isolate the worked out section from the outside; (2) arranging a gas inlet pipeline in at least one enclosed wall body on the lower part of the worked out section; (3) connecting pumped gas with the gas inlet pipeline at the inner side of the enclosed wall body through a fire arrestor at the outer side of the enclosed wall body; (4) forming at least one drill hole in a fissure zone on the upper part of the worked out section to collect enriched gas; and (5) connecting the drill hole with a gas outlet pipeline through the fire resistor. By adopting the method, huge inbreak space of the underground worked out section is fully utilized, natural separation of gas from the air is realized by using the property that gas is lighter than the air under the condition of low separating cost, the concentration oflow-concentration gas with high separation cost by using a manual device is increased to be over than 40 percent, and 100 percent separation and purification of gas pumped from a mine is realized.

Owner:CHINA SHENHUA ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com