Method for depolymerising oxygenated polymer materials by nucleophilic catalysis

A polymer and compound technology, applied to aliphatic compounds in the construction industry, petrochemical industry, electrical fields, can solve the problems of several types of recycling, and achieve the effect of large industrial value and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

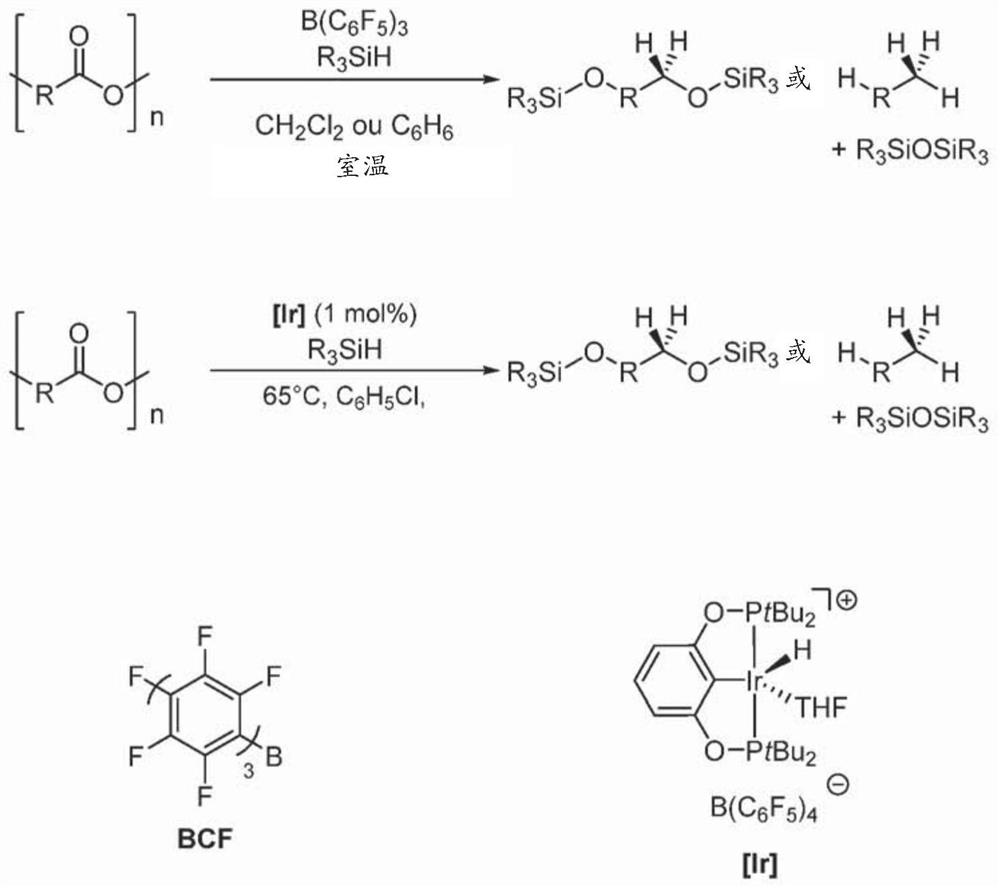

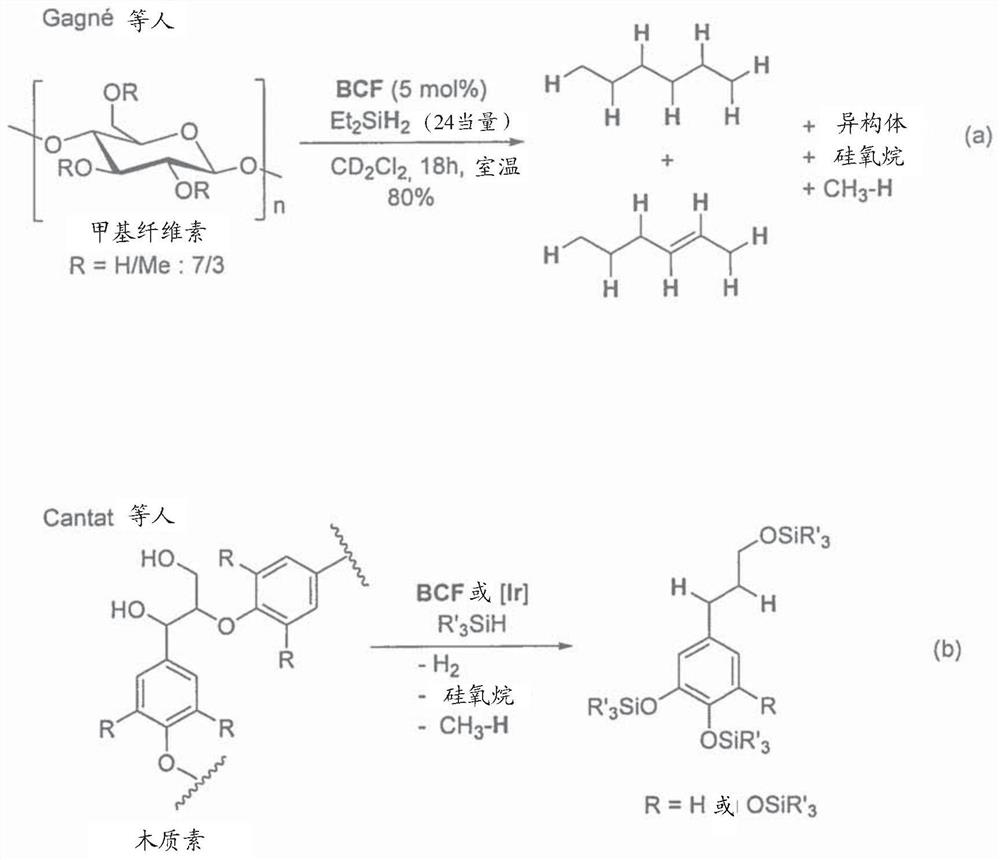

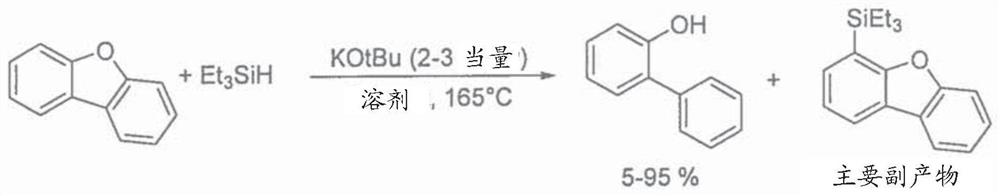

Method used

Image

Examples

Embodiment 1

[0267]Example 1 : Trimethoxysilane ((MEO)3SiH) and Kotbu to solve PC-BPA

[0268]

[0269]The commercially available PC-BPA (123.2 mg; 0.5 mmol; 1 mole) and trimethoxysilane (244 mg; 2 mmol; 4 molar equivalents) were added to 1.5 ml of THF. The KOTBU catalyst (0.05 molar equivalents) was added while stirring. The reaction was reacted at room temperature (20 ° C ± 5 ° C), and then the solvent was evaporated under vacuum. The resulting product IIA was purified by using the same conditions described in the general method of operation. By purification, a product IIa having very high purity is obtained, wherein the yield is 97% relative to the introduced starting material.

[0270]At 25 ° C, 10 mL of NaOH (10%) in the methanol / water mixture was directly added to the reaction mixture, and a hydroxy product of a 2-hour product IIa was performed. The hydrolyzate (BPA) of the white solid was obtained by purification by the column using the condition described in the general operation method.

Embodiment 2

[0271]Example 2 : Trimethoxysilane ((MEO)3SiH)) and TBAT to explain PC-BPA

[0272]

[0273]Using (MEO)3SiH and KOTBUs to explain the same manner as in Example 1 of PC-BPA, and to deliver with TBAT (0.05 molar equivalents). In this case, 123.2 mg of PC-BPA (0.5 mmol; 1 molar equivalents) with 244 mg of trimethoxysilane (244 mg; 2 mmol; 4 molar equivalents) and 0.05 molar equivalent TBAT (13.5 mg, 0.025 mmol, 5 mol%) is used together. After 6 hours, it was completely converted into IIA. The product was purified by the same method of operation as in Example 1.

[0274]The hydrolysis of the product IIa made BPA (white solid, yield of 92%).

Embodiment 3

[0275]Example 3 : Trimethoxysilane ((MEO)3SiH) and TBAF (1M in THF) to solve PC-BPA

[0276]

[0277]Using (MEO)3SiH and KOTBUs to explain the same manner as in Example 1 of PC-BPA, and the TBAF (1M in THF) is given. In this case, 123.2 mg of PC-BPA (0.5 mmol; 1 molar equivalents) was used to trimethoxysilane (244 mg; 2 mmol; 4 molar equivalents) and 50 μl of TBAT (0.05 mmol, 0.1 molar equivalents). After 12 hours, it was completely converted into IIA.

[0278]The product was purified by the same method of operation as in Example 1. The hydrolysis of the product IIa made BPA (white solid, yield of 92%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com