Method for preparing D-mannose

A technology of mannose and miscellaneous sugars, which is applied in the field of D-mannose preparation, can solve the problems of high temperature control equipment requirements, high cost of enzymatic degradation, increased energy consumption costs, etc., to reduce energy consumption, save concentration costs, simplify The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

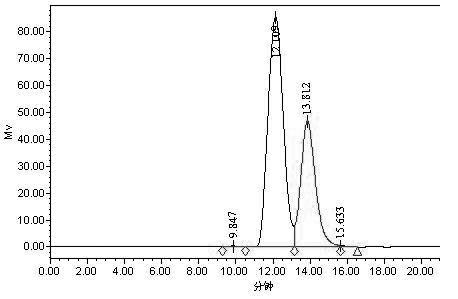

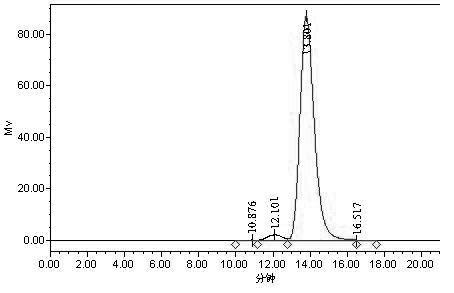

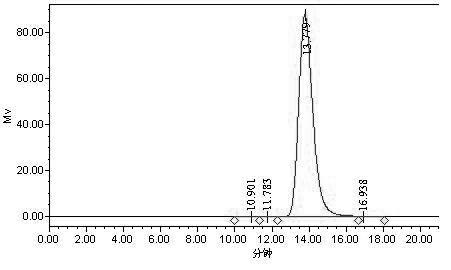

Image

Examples

Embodiment 1

[0040] The preparation method of D-mannose of the present invention comprises the following steps:

[0041](1) Dilute 5kg of anhydrous crystalline glucose with pure water to a concentration of 65%, add 5g of catalyst ammonium molybdate, and carry out epimerization at 125°C and 0.12Mpa to partially convert glucose into mannose, isomerize After the end, the content of mannose in the mixed solution was 31.6%.

[0042] (2) The glucose and mannose mixed solution obtained after isomerization is decolorized by activated carbon, desalted and refined by ion exchange resin to obtain the glucose and mannose mixed solution A.

[0043] (3) The mixed solution A enters the simulated moving bed for separation and purification to obtain a mannose-rich component A1 and a glucose-rich component A2, wherein the mannose content in the mannose-rich component A1 is 81%, The miscellaneous sugar content is 0.42%, the mannose content of the glucose-rich fraction is 11%, and the miscellaneous sugar con...

Embodiment 2

[0053] The preparation method of D-mannose of the present invention comprises the following steps:

[0054] (1) Dilute 5kg of anhydrous crystalline glucose with pure water to a concentration of 65%, add 5g of catalyst ammonium molybdate, and carry out epimerization at 125°C and 0.12Mpa to partially convert glucose into mannose, isomerize After the end, the content of mannose in the mixed solution was 31.6%.

[0055] (2) The glucose and mannose mixed solution obtained after isomerization is decolorized by activated carbon and desalted and refined by ion exchange resin to obtain the glucose and mannose mixed solution A.

[0056] (3) Separating and purifying the mixed solution A through a simulated moving bed to obtain a mannose-rich component A1 and a glucose-rich component A2, wherein the mannose content in A1 is 81%, and the miscellaneous sugar content is 0.42%, The mannose content in the glucose-rich fraction is 11%, and the miscellaneous sugar content is 2.1%.

[0057] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com