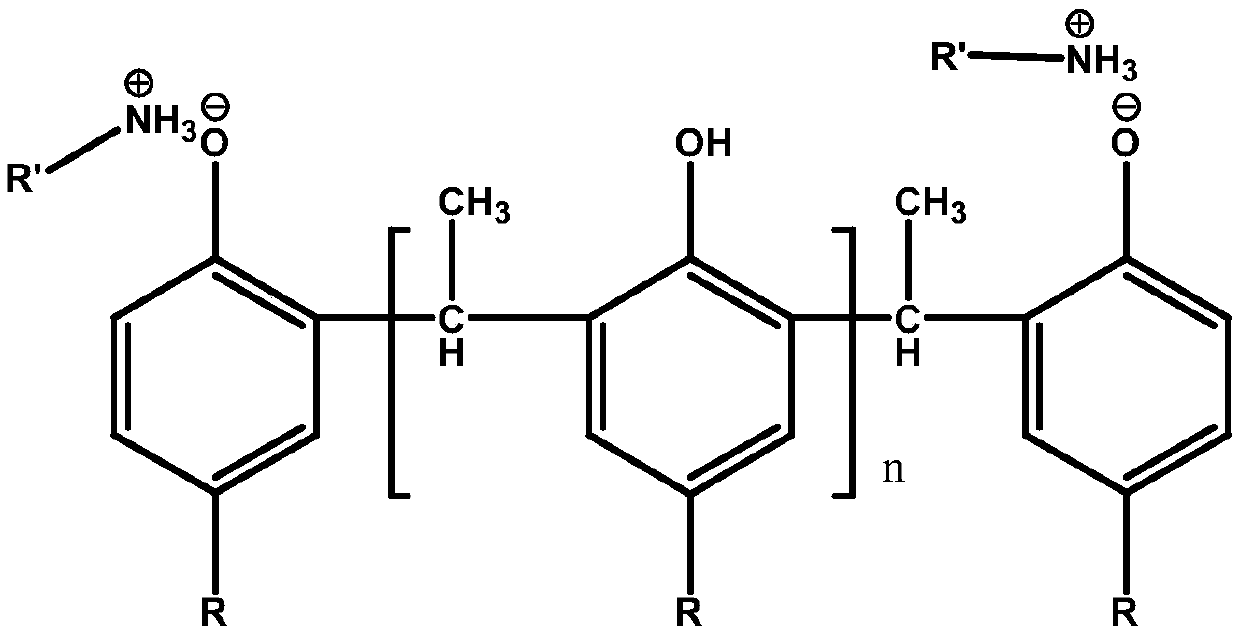

Amino acid modified alkylphenol-formaldehyde resin and preparation method thereof

A formaldehyde resin and amino acid technology, applied in the field of tackifying resins, can solve the problems that alkylphenol-formaldehyde resins do not have storage stickiness, wet heat stickiness, can not meet the production needs of high-end tires and rubber products, and the production process is complicated, etc., to achieve the goal of tackifying Excellent permanence and wet-heat tack performance, improved initial tack and long-lasting tack, and reduced migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

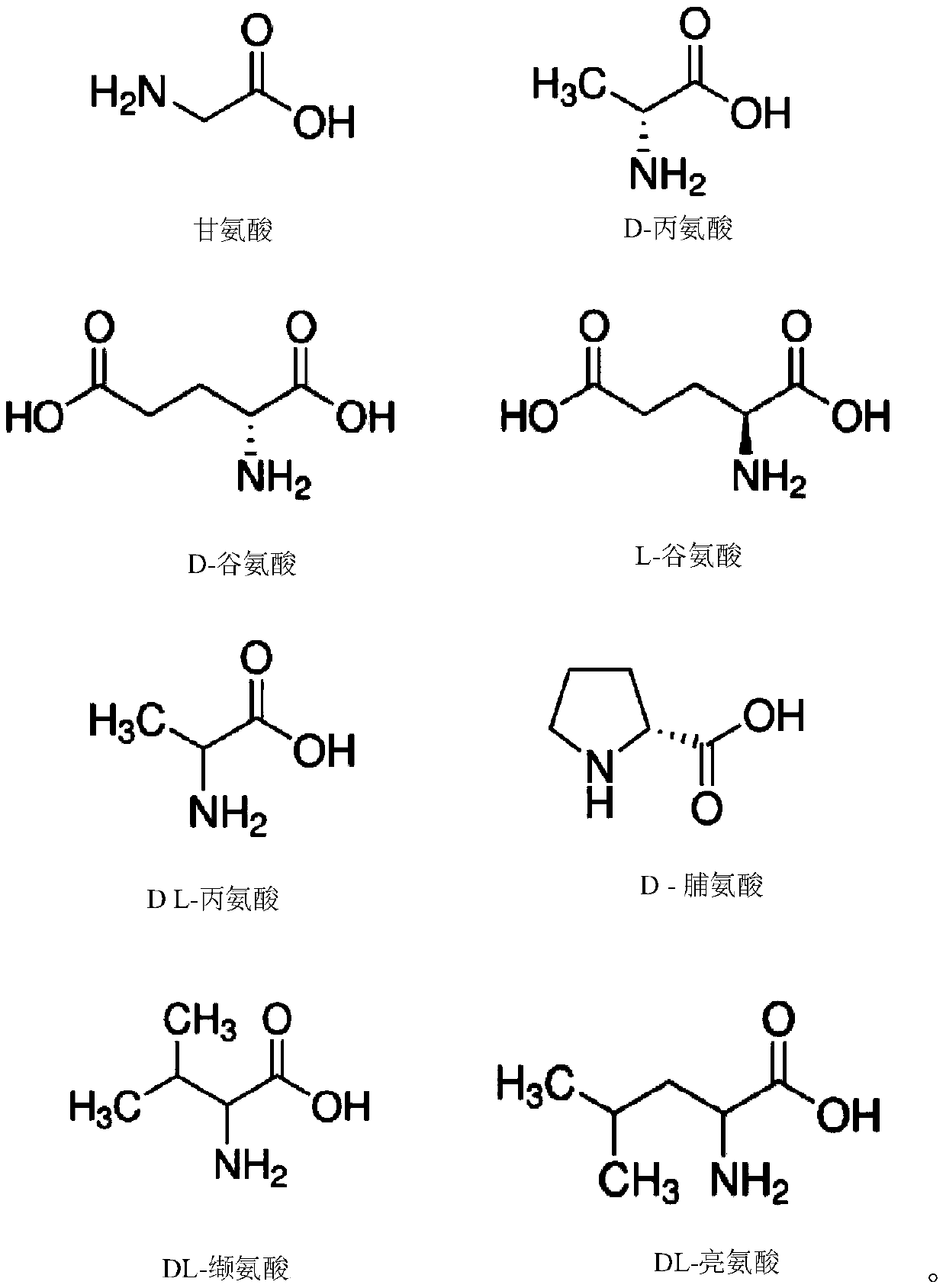

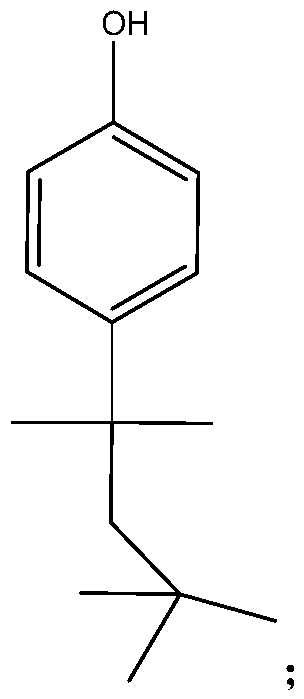

[0044] In the synthesis of amino acid modified p-tert-butylphenol-formaldehyde resin, concentrated sulfuric acid is used as an acidic catalyst, p-tert-butylphenol, liquid formaldehyde and solid formaldehyde are used as raw materials, and the mixture of DL-leucine is used as a modifier. Butylphenol: liquid formaldehyde: solid formaldehyde (molar ratio) = 1:0.51:0.34; amino acid addition is 5% of p-tert-butylphenol. Specific steps are as follows:

[0045] Step 1: Add 100 g (0.67 mol) of p-tert-butylphenol and 0.2 g of concentrated sulfuric acid to a 500 ml four-necked round-bottomed reaction flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel. The temperature was raised to 90°C, 41.8g of formaldehyde solution (37wt%) was slowly added dropwise, and the reaction was refluxed for 1h;

[0046] Step 2: After the reflux reaction, 5.0 g of amino acid was added to carry out the modification reaction, and the reaction was continued for 1 hou...

Embodiment 2

[0049] In the synthesis of amino acid modified p-tert-butylphenol-formaldehyde resin, hydrochloric acid is used as an acidic catalyst, p-tert-octylphenol, liquid formaldehyde and solid formaldehyde are used as raw materials, and the mixture of D-glutamic acid and L-glutamic acid is used as Modifier, p-tert-octylphenol: liquid formaldehyde: solid formaldehyde (molar ratio) = 1:0.54:0.36; amino acid addition is 5% of p-tert-butylphenol. Concrete steps are with embodiment 1.

[0050] The product is weighed under cooling, and the productive rate is 99% based on alkylphenol. After measurement, the softening point of this resin is 108 ℃, and the molecular weight measured by gel permeation chromatography (GPC) method is 1672g / mol, and the mass percentage of free p-tetylphenol in the resin measured by bromination method is 0.6%. , the moisture mass content is less than 1%.

Embodiment 3

[0052] Synthesis of amino acid modified p-tertyl phenol-formaldehyde resin, using p-toluenesulfonic acid as an acidic catalyst, p-tertyl phenol, liquid formaldehyde and solid formaldehyde as raw materials, and a mixture of DL-alanine as a modifier; p-tert-octylphenol: liquid formaldehyde: solid formaldehyde (molar ratio)=1:0.54:0.36; amino acid addition is 5% of p-tert-butylphenol. Concrete steps are with embodiment 1.

[0053] The product is weighed under cooling, and the productive rate is 99% based on alkylphenol. After measuring, the softening point of this resin is 138 ℃, and the molecular weight measured by gel permeation chromatography (GPC) method is 1701g / mol, and the mass percentage of free p-tetylphenol in the resin measured by bromination method is 0.5%. , the moisture mass content is less than 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com