Method for preparing natural 2-benzyl carbinol

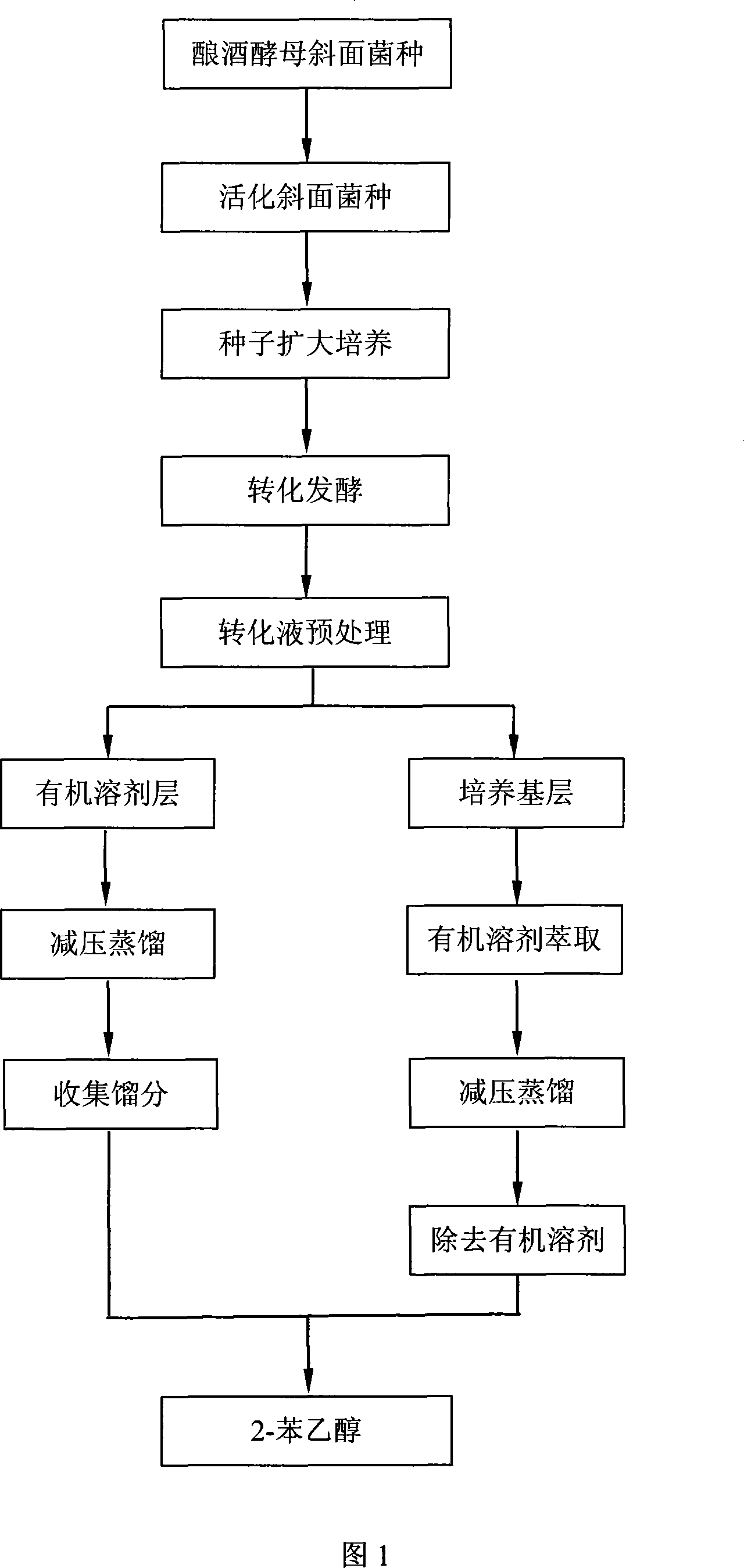

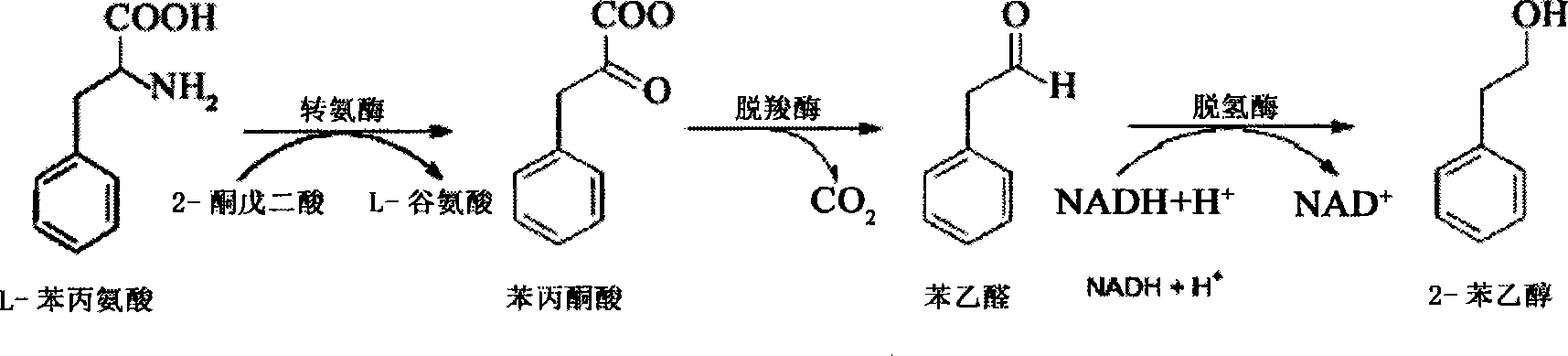

A phenylethanol and natural technology, applied in the field of biotransformation to produce natural 2-phenylethanol, can solve the problems that hinder the industrial application of 2-phenylethanol, toxicity, limit the concentration of 2-phenylethanol conversion and synthesis, and achieve large-scale industrial application , Short production cycle, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The culture medium formula of the present embodiment is:

[0036] Slant medium: glucose 10g / L, peptone 5g / L, yeast extract powder 3g / L, agar 15g / L, solvent is water, pH is natural, sterilized by high pressure steam at 121°C for 20min.

[0037] Seed medium: glucose 20g / L, peptone 10g / L, yeast extract powder 5g / L, solvent is water, pH is natural, sterilized by high pressure steam at 121°C for 20min.

[0038] Transformation medium: sucrose 100g / L, yeast extract powder 5g / L, KH 2 PO 4 7.5g / L, K 2 HPO 4 ·3H 2 O 12.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the solvent is water, the pH is natural, and sterilized by high-pressure steam at 121°C for 20min.

[0039] First pick a ring full of cells from the slant strain of Saccharomyces cerevisiae preserved in the refrigerator, inoculate it in a fresh slant medium, and culture the slant surface in a biochemical incubator at 25°C for 36 hours to obtain an activated slant surface of Saccharomyces cerevisiae strain. Pick 2 rings of bacte...

Embodiment 2

[0045] The culture medium formula of the present embodiment is:

[0046] Slant medium: glucose 20g / L, peptone 10g / L, yeast extract powder 5g / L, agar 20g / L, solvent is water, pH is natural, sterilized by high pressure steam at 121℃ for 20min.

[0047] Seed medium: glucose 40g / L, peptone 20g / L, yeast extract powder 10g / L, solvent is water, pH is natural, sterilized by high pressure steam at 121°C for 20min.

[0048] Transformation medium: sucrose 20g / L, yeast extract powder 6.0g / L, KH 2 PO 4 7.5g / L, K 2 HPO 4 ·3H 2 O 12.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the solvent is water, the pH is natural, and sterilized by high-pressure steam at 121°C for 20min.

[0049] First pick a ring full of cells from the Saccharomyces cerevisiae slant strain stored in the refrigerator, inoculate it in a fresh slant medium, and culture the slant surface in a biochemical incubator at 30°C for 24 hours to obtain an activated Saccharomyces cerevisiae strain slant. Pick 2 rings of bacteria from the ac...

Embodiment 3

[0054] The culture medium formula of the present embodiment is:

[0055] Slant medium: glucose 10g / L, peptone 5g / L, yeast extract powder 3g / L, agar 15g / L, solvent is water, pH is natural, sterilized by high pressure steam at 121°C for 20min.

[0056] Seed medium: glucose 20g / L, peptone 10g / L, yeast extract powder 5g / L, solvent is water, pH is natural, primary seed medium and secondary seed medium have the same composition, sterilized by high pressure steam at 121°C for 20min.

[0057] The composition of the transformation medium is: sucrose 120g / L, yeast extract powder 6.0g / L, KH 2 PO 4 7.5g / L, K 2 HPO 4 ·3H 2 O12.6g / L, MgSO 4 ·7H 2 O 0.5g / L, the solvent is water, the pH is natural, and sterilized by high-pressure steam at 121°C for 30min.

[0058] Pick a ring full of cells from the slant strain of Saccharomyces cerevisiae stored in the refrigerator, inoculate it in a fresh slant medium, and culture the slant in a biochemical incubator at 30°C for 24 hours to obtain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com