Method for treating heavy emulsified oil in waste water

A technology for treating wastewater and emulsified oil, applied in separation methods, grease/oily substances/suspton removal devices, liquid separation, etc., can solve the separation effect of heavy emulsified oil wastewater that has not been reported, high energy consumption of air flotation separation, separation Low efficiency and other problems, to avoid transmission and circulation, simplify the processing technology and process, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

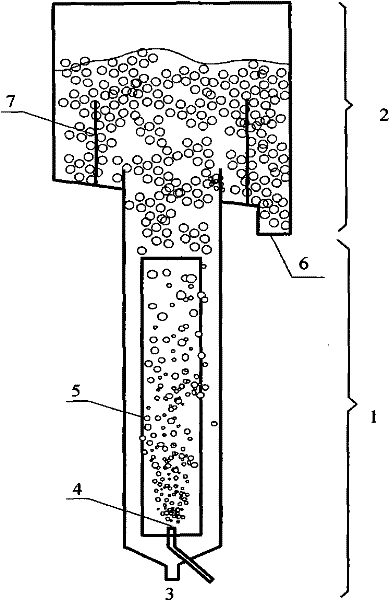

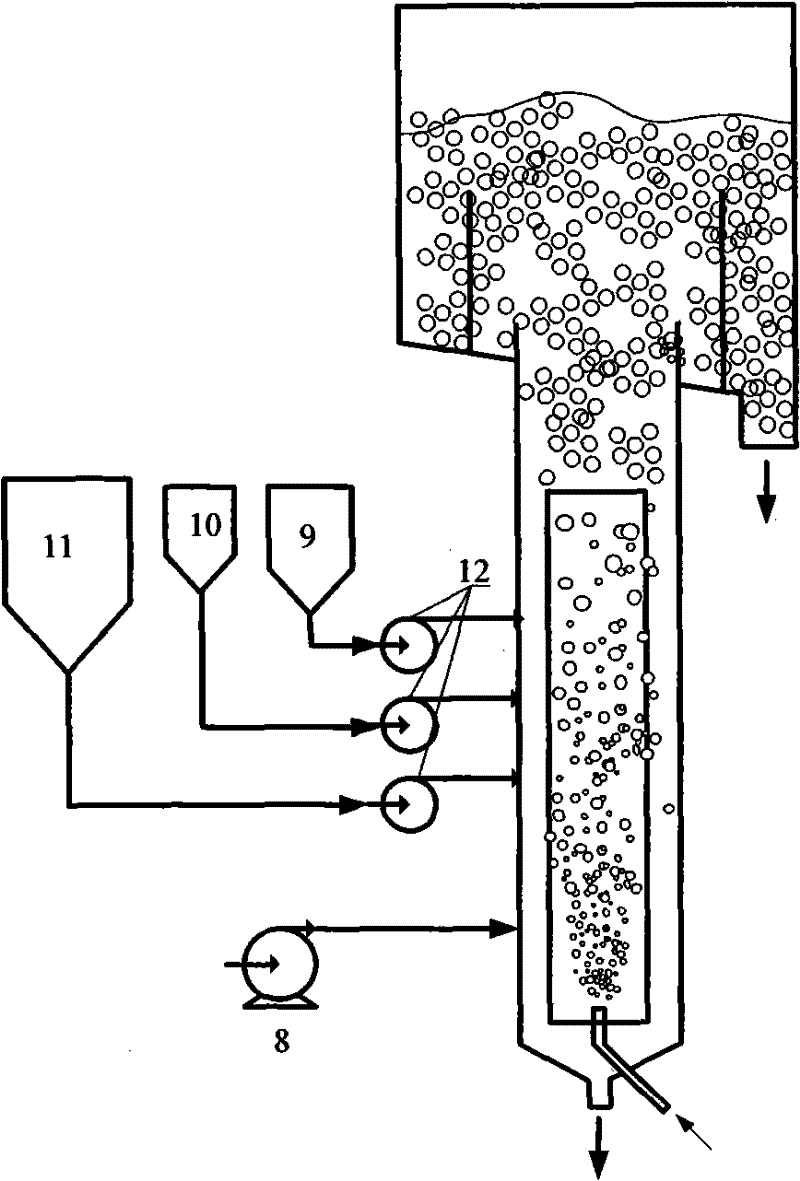

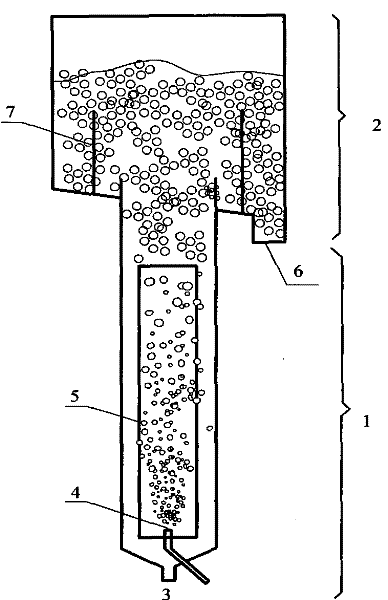

[0028] The heavy emulsified oil in wastewater is separated by continuous operation mode and flocculation-circulation foam.

[0029] The wastewater is condensed water from heavy oil processing coking steam blowing in a refinery. The total COD is 22000mg / L, of which the COD of emulsified oil and other colloidal suspended matter is 20000mg / L, and the average diameter of emulsion droplets is 2.5μm. The diameter of the bubble section of the circulating foam separation tower is 192mm, and the height is 1500mm; the diameter of the foam section is 340mm, and the height is 680mm; the diameter of the overflow weir is 260mm, and the height is 90mm. Among them, the height of the first stage is 560mm; the center of the bottom of the reactor is equipped with a special microporous (average pore diameter of 3μm) columnar gas distributor (20mm in diameter, 60mm in height), and the liquid capacity is 42L. Inorganic flocculant is AlCl 3 , the dosage is 2.3g (ie 0.02mmol / g COD emulsified oil), a...

Embodiment 2

[0031] Batch operation mode, flocculation-circulation foam separation of heavy emulsified oil in wastewater.

[0032] Waste water and device are with embodiment 1. Inorganic flocculant is AlCl 3 , the dosage is 5.6g (that is, 0.05mmol / g COD emulsified oil), and it is prepared into an aqueous solution with a concentration of 47g / L, and is added to the bubbling section at a flow acceleration rate of 80mL / h; the dosage of polyacrylamide is 1.05mg, (that is, 25mg / L m 3 waste water), prepared into an aqueous solution with a content of 50mg / L, and added to the bubbling section at a flow rate of 14mL / h; the surfactant is sodium dodecylsulfonate (SDBS), and the dosage is 8.4g (that is, 10mg / g COD emulsified oil), prepared into an aqueous solution with a content of 10.5g / L, added to the bubbling section at a flow rate of 0.4L / h; the superficial gas velocity was 1.1cm / s, and the separation time was 1.5h. The effluent COD is 1400mg / L, and the removal rate of emulsified oil reaches 94%...

Embodiment 3

[0034] This example shows the removal effect of emulsified oil under the condition of different surfactant dosage, and adopts batch operation.

[0035] Waste water and device are with embodiment 1. Inorganic flocculant is AlCl 3 , the dosage is 2.3g (that is, 0.02mmol / g COD emulsified oil), and it is prepared into an aqueous solution with a concentration of 23g / L, and is added to the bubbling section at a flow acceleration rate of 50mL / h; the dosage of polyacrylamide is 1.05mg, (that is, 25mg / L m 3 Wastewater), prepared into an aqueous solution with a content of 50mg / L, added to the bubbling section at a flow rate of 14mL / h; the superficial gas velocity was 1.1cm / s, the surfactant was SDS, and the separation time was 2h. The amount of SDS is 0.84g (ie 1mg / g COD emulsified oil, solution concentration 5.3g / L, flow acceleration rate 80mL / h), 4.2g (ie 5mg / g COD emulsified oil, solution content 10.5g / L, flow acceleration rate 0.2L / h), 8.4g (ie 10mg / g COD emulsified oil, solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com