Apparatus and methods for defining a plasma

A technology of plasma and equipment, applied in the field of plasma, can solve problems such as unsuitable substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

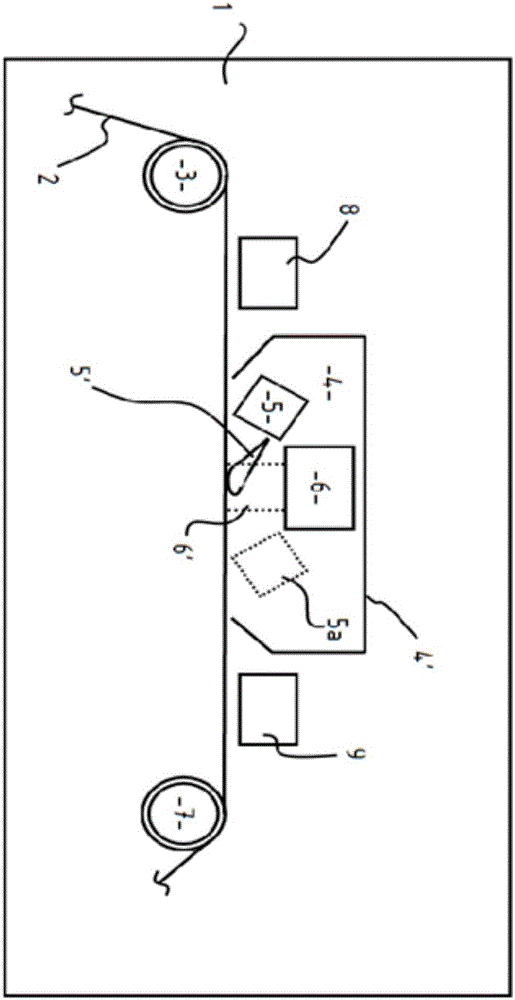

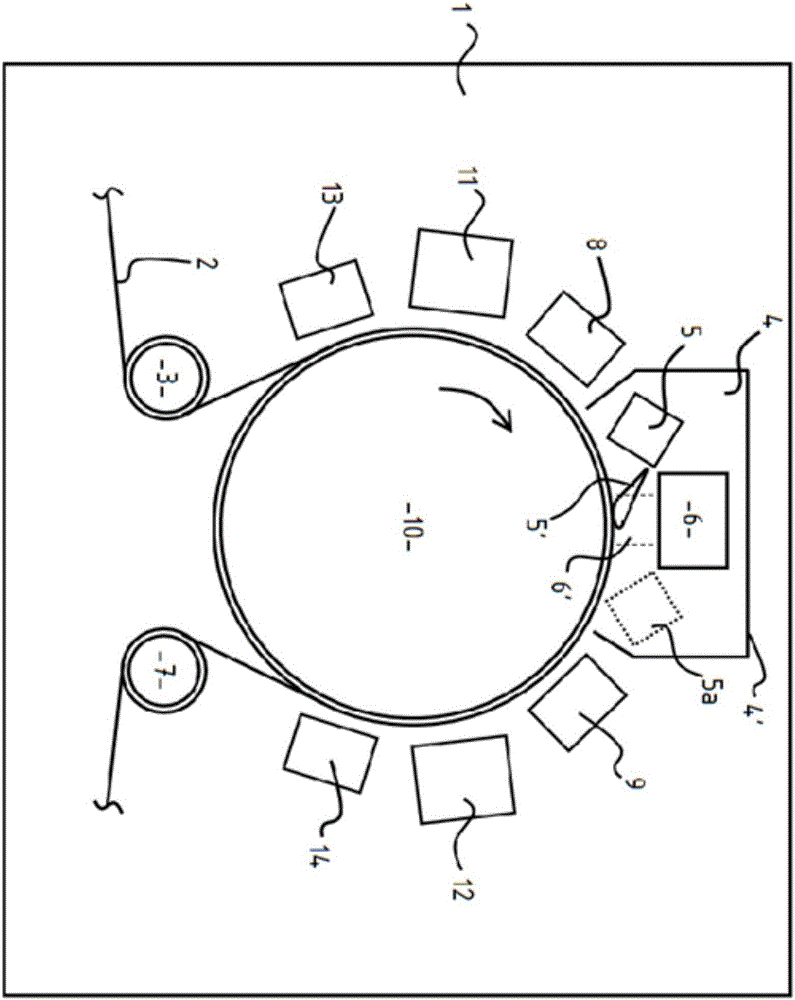

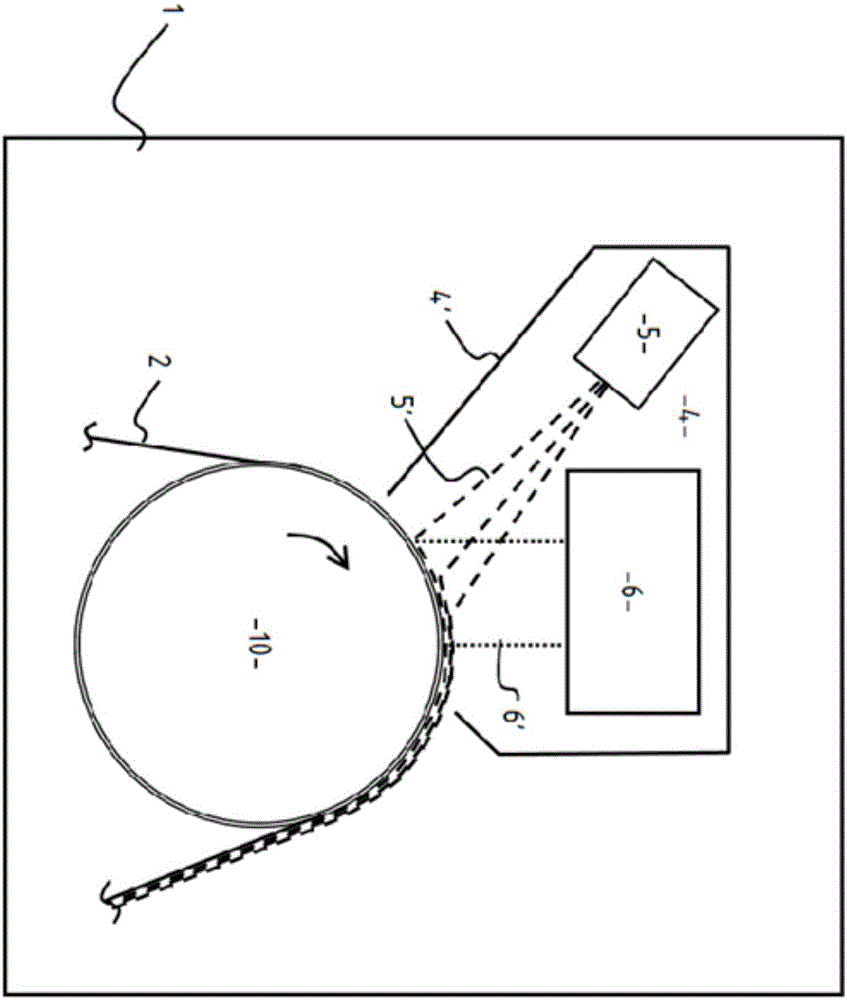

[0114] figure 1 The shown apparatus is housed in a vacuum chamber 1, and a coated substrate 2 to be treated is fed to a guide between a coated substrate unwinding (not shown) and a coated substrate rewinding chamber (not shown). On free guide rollers 3, 7, the coated substrate 2 is fed through a coating chamber 4, which is formed by an outer packaging 4' in which is placed a device for producing radiation curing. A radiation curing material directional beam generator 5 for a material directional beam 5', and a low-pressure gas plasma source 6 for generating a directional ion flow 6'. The directed ion flow may include cations as well as other positively charged or uncharged particles and species, however, only these positively charged ions are the primary initiators of the curing or treating process. Typical plasma ionization fractions can be in the range of 10 -5 to 10 -1 between. As the coated substrate passes beneath the radiation-curable material directional beam genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com