Treatment process of recycled waste water from polysilicon cutting waste mortar

A technology for cutting waste sand and processing technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult wastewater discharge, water environment hazards, etc., to achieve The effect of reducing pollutant discharge, simple management, and low construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

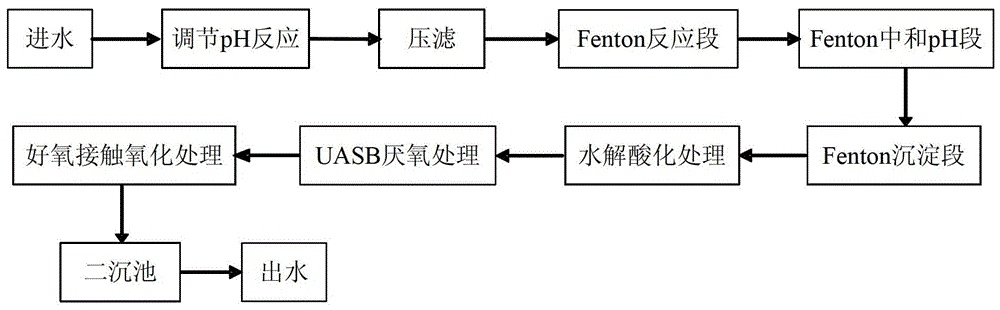

[0031] A trial production test was carried out on a polysilicon cutting mortar recycling wastewater treatment process (see attached figure 1 ), the system design water volume is 800m 3 / d. Influent water (most data) indicators are: COD concentration is 15000mg / L~25000mg / L, pH is 11~13, SS (suspended solids in water quality) concentration is 10000mg / L~30000mg / L, silicate concentration is 20000mg / L L~30000mg / L.

[0032] Polysilicon cutting mortar recycling wastewater treatment process: adjust the pH of the polysilicon cutting mortar recycling wastewater to react to precipitate silicate radicals and flocculate the suspended solids of silicon carbide powder, then pass through plate and frame filter press to achieve solid-liquid analysis, then oxidize it by Fenton, and then undergo hydrolysis and acidification Treatment, followed by UASB anaerobic treatment, then contact oxidation aerobic treatment, and finally solid-liquid separation through the secondary sedimentation tank. in...

Embodiment 2

[0042] A trial production test was carried out on the waste water recovered from a polysilicon cutting mortar. The design water volume of the system is 600m 3 / d. Influent water (most data) indicators are: COD concentration is 15000mg / L~25000mg / L, pH is 11~13, SS (suspended solids in water quality) concentration is 10000mg / L~30000mg / L, silicate concentration is 20000mg / L L~30000mg / L.

[0043] Polysilicon cutting mortar recycling wastewater treatment process: adjust the pH of the polysilicon cutting mortar recycling wastewater to react to precipitate silicate radicals and flocculate silicon carbide powder suspensions, then pass through plate and frame filter press to achieve solid-liquid analysis, then oxidize it by Fenton, and then undergo hydrolysis and acidification treatment, followed by UASB anaerobic treatment, then contact oxidation aerobic treatment, and finally solid-liquid separation through the secondary sedimentation tank; among them,

[0044] The described remova...

Embodiment 3

[0053] Trial production test was carried out on polysilicon cutting mortar recovery wastewater treatment process, the design water volume of the system is 700m 3 / d. Influent water (most data) indicators are: COD concentration is 15000mg / L~25000mg / L, pH is 11~13, SS (suspended solids in water quality) concentration is 10000mg / L~30000mg / L, silicate concentration is 20000mg / L L~30000mg / L.

[0054] Polysilicon cutting mortar recycling wastewater treatment process: adjust the pH of the polysilicon cutting mortar recycling wastewater to react to precipitate silicate radicals and flocculate silicon carbide powder suspensions, then pass through plate and frame filter press to achieve solid-liquid analysis, then oxidize it by Fenton, and then undergo hydrolysis and acidification treatment, followed by UASB anaerobic treatment, then contact oxidation aerobic treatment, and finally solid-liquid separation through the secondary sedimentation tank; among them,

[0055] The described rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com